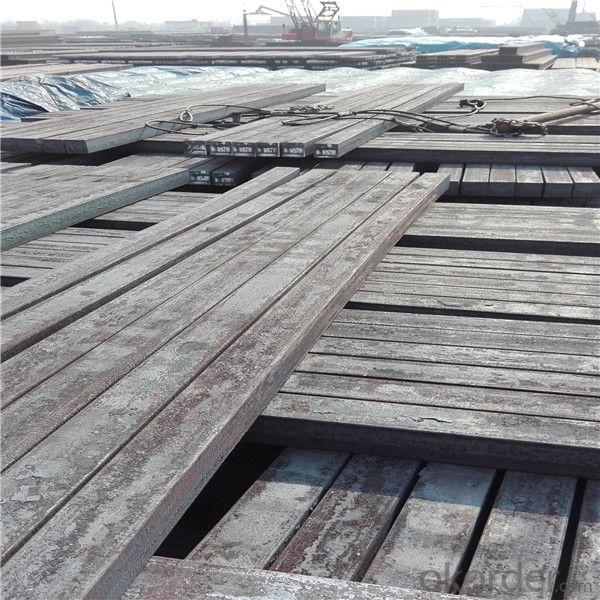

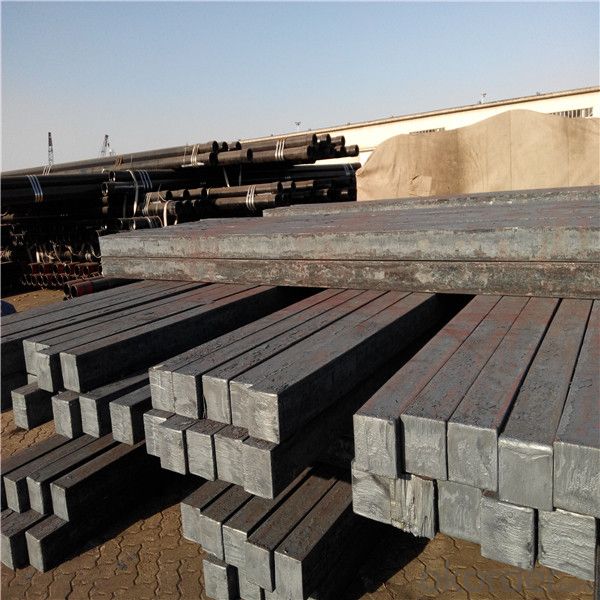

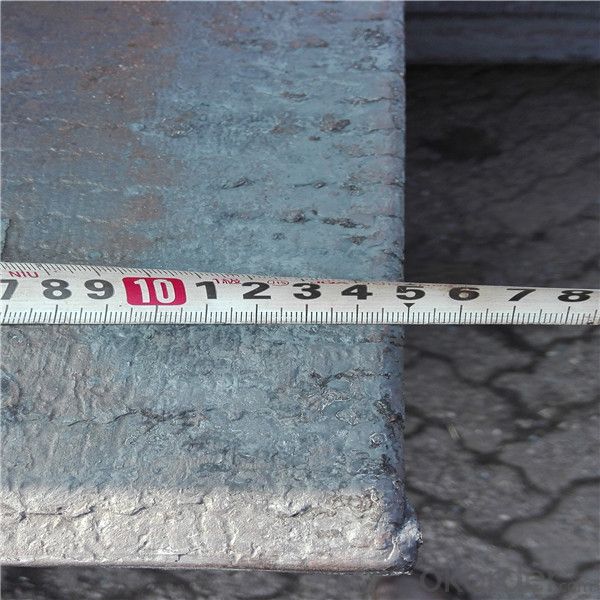

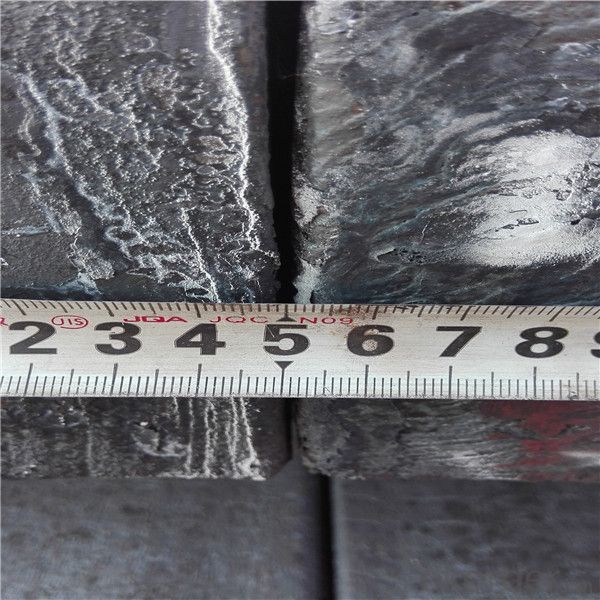

Prime Square Steel Billet 150x150mm 165x165mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19684 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the

support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the main factors affecting the tensile strength of steel billets?

- There are several main factors that affect the tensile strength of steel billets. Firstly, the composition of the steel plays a significant role. The presence of certain elements, such as carbon, manganese, and silicon, can greatly influence the strength of the steel. Carbon, in particular, is a key element in increasing the strength of steel through its ability to form strong interatomic bonds. Secondly, the heat treatment process employed during the production of steel billets is crucial. Heat treatment, such as quenching and tempering, can significantly enhance the tensile strength of the steel by manipulating its microstructure. Quenching involves rapidly cooling the steel, which creates a hardened structure, while tempering involves reheating the steel to a specific temperature to achieve the desired balance of hardness and toughness. Additionally, the grain size of the steel also affects its tensile strength. Fine-grained steel generally exhibits higher strength due to the increased number of grain boundaries, which act as barriers to dislocation movement. On the other hand, coarse-grained steel tends to have lower strength as it allows for easier dislocation movement. Moreover, the presence of impurities or defects in the steel can weaken its tensile strength. Inclusions, such as sulfur, phosphorus, and non-metallic inclusions, can act as stress concentration points and promote crack initiation, leading to reduced strength. Similarly, the presence of voids, porosity, or other structural defects can compromise the overall strength of the steel billets. Lastly, the processing conditions during the manufacturing of steel billets can affect their tensile strength. Parameters such as rolling and forging temperatures, deformation rate, and cooling rate can influence the resulting microstructure and, consequently, the strength of the steel. In conclusion, the main factors affecting the tensile strength of steel billets include the steel composition, heat treatment process, grain size, impurities or defects, and processing conditions. Understanding and optimizing these factors are crucial for producing steel billets with the desired mechanical properties.

- Q: What are the safety precautions to be followed while handling steel billets?

- When handling steel billets, it is important to follow certain safety precautions to prevent accidents and injuries. Some of the key safety measures to be followed include: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves, safety glasses, and steel-toed boots, to protect yourself from potential hazards like sharp edges or falling objects. 2. Lifting Techniques: Use proper lifting techniques and equipment, such as cranes or forklifts, to handle steel billets. Avoid attempting to lift them manually, as they can be heavy and may cause strain or back injuries. 3. Secure Storage and Transportation: Ensure that steel billets are securely stored and transported to prevent them from rolling or falling. Use appropriate containers or racks to keep them stable and avoid any mishaps. 4. Avoid Overloading: Do not overload lifting equipment or storage containers beyond their recommended weight limits. Exceeding these limits can compromise their stability and lead to accidents. 5. Clear Work Area: Maintain a clean and organized work area, free from clutter or debris, to prevent slips, trips, and falls while handling steel billets. 6. Proper Training: Ensure that all personnel involved in handling steel billets receive proper training on safe handling practices, equipment usage, and emergency procedures. 7. Communication and Signage: Clearly communicate and display warning signs or labels indicating the presence of steel billets in the vicinity, helping to prevent accidental contact or collisions. By following these safety precautions, you can minimize the risks associated with handling steel billets and maintain a safe working environment.

- Q: What are the different grades of steel used for producing billets?

- The different grades of steel used for producing billets vary depending on the specific requirements and applications. Some common grades include mild steel, low carbon steel, medium carbon steel, high carbon steel, alloy steel, and stainless steel. Each grade offers different mechanical properties, such as strength, durability, and corrosion resistance, to meet the desired characteristics for the final product.

- Q: What are the common applications of steel billets?

- Steel billets are commonly used as raw material for the production of various steel products, such as bars, rods, wire, pipes, and tubes. They are also utilized in the automotive industry for manufacturing parts like crankshafts, camshafts, and gears. Additionally, steel billets find applications in construction for producing structural elements like beams, columns, and girders.

- Q: How are steel billets used in the production of railway wheels?

- Steel billets are an indispensable element for manufacturing railway wheels. These billets, which are essentially semi-finished forms of steel, serve as the initial stage of the production process. To begin the production of railway wheels, the steel billets are subjected to high temperatures in a furnace. This heating process, known as hot rolling, enhances the steel's malleability and ductility, making it easier to shape. Once the billets have reached the desired temperature, they undergo a series of rolling operations. These operations gradually shape the billets into the required size and form for railway wheels. High pressure is applied to the billets during this rolling process, causing them to elongate and take on the desired shape. After the rolling process, the shaped billets undergo further processing to eliminate any excess material and refine the surface finish. This step ensures that the final product meets all the necessary specifications for railway wheels. Lastly, the shaped billets are sent for additional machining, where they are turned, drilled, and finished to create the final railway wheel. This machining process is essential in achieving the required dimensions, balance, and surface quality needed for safe and efficient operation. In conclusion, steel billets play a vital role in the production of railway wheels. They are heated, rolled, shaped, and further processed to create the essential components for the final product. Without steel billets, the production of railway wheels would not be feasible.

- Q: What are the main factors affecting the quality of steel billets?

- The main factors affecting the quality of steel billets include the composition of the raw materials used, the temperature and duration of the heating process, the cooling rate, and the presence of impurities or defects in the final product. Additionally, the quality of the equipment and machinery used during the production process, as well as the expertise and experience of the workers, can also significantly impact the quality of steel billets.

- Q: What is the role of steel billets in the manufacturing of construction machinery?

- Steel billets play a crucial role in the manufacturing of construction machinery as they serve as the raw material for producing various components and structures. These billets are initially heated and then shaped or machined into different forms such as plates, beams, or rods, which are essential in constructing the frames, chassis, and other structural parts of construction machinery. The high strength and durability of steel make it ideal for withstanding heavy loads and harsh working conditions, ensuring the reliability and longevity of construction machinery.

- Q: What are the different types of steel billet cutting defects?

- There are several different types of steel billet cutting defects that can occur during the cutting process. These defects can have varying degrees of severity and can impact the quality and integrity of the final product. Some common types of steel billet cutting defects include: 1. Burr formation: Burrs are small, unwanted pieces of metal that are left behind on the edges of the cut. They can be caused by factors such as improper cutting blade alignment, excessive cutting speed, or worn-out cutting blades. Burrs can affect the dimensional accuracy of the billet and may require additional processing to remove. 2. Cracks: Cracks can occur during the cutting process due to the high stress and heat generated. They can result from factors such as improper cutting speed, inadequate cooling, or material inconsistencies. Cracks can compromise the structural integrity of the billet and can lead to failure in the final product. 3. Surface imperfections: Surface imperfections can include scratches, dents, or gouges on the surface of the billet. These defects can be caused by factors such as improper handling, inadequate lubrication, or worn-out cutting blades. Surface imperfections can affect the appearance of the final product and may require additional processing to rectify. 4. Incorrect dimensions: Cutting defects can also manifest as deviations from the desired dimensions of the billet. These deviations can arise from factors such as improper cutting blade alignment, inaccurate measurements, or machine malfunctions. Incorrect dimensions can result in compatibility issues during subsequent processing steps or in the final product. 5. Slag inclusion: Slag is a byproduct that can be present in the steel billet. During the cutting process, if the cutting blade encounters slag, it can become embedded in the cut edge. Slag inclusion can lead to structural weakness and reduced mechanical properties in the final product. It is essential to identify and rectify these cutting defects to ensure the production of high-quality steel billets. Regular maintenance and inspection of cutting equipment, proper training of operators, and adherence to quality control measures can help minimize these defects and ensure the production of defect-free steel billets.

- Q: How are steel billets inspected before they are used in production?

- Steel billets are inspected thoroughly before they are used in production to ensure their quality and adherence to the required specifications. The inspection process typically involves several key steps. Firstly, visual inspection is conducted to examine the surface of the billets for any surface defects such as cracks, seams, or deformities. Any irregularities can indicate potential weaknesses or problems in the billet that may affect its performance during production. Secondly, dimensional inspection is performed to verify the billet's size, length, width, and other critical dimensions. This is crucial to ensure that the billets meet the precise requirements of the production process and can be seamlessly integrated into the manufacturing operations. Thirdly, ultrasonic testing is often employed to detect any internal defects or discontinuities within the billets. Ultrasonic waves are passed through the billet, and any reflections or echoes are analyzed to identify any flaws such as voids, inclusions, or cracks that may compromise the structural integrity of the billets. Additionally, magnetic particle inspection may be carried out to identify surface or near-surface defects that may not be visible to the naked eye. This technique involves applying magnetic particles to the surface of the billet and detecting any magnetic leakage caused by defects through the use of magnetic fields. Furthermore, chemical analysis is frequently performed to ensure that the steel billets have the desired chemical composition. This involves taking samples from the billets and subjecting them to various tests to determine the percentages of different elements present. This analysis guarantees that the billets possess the necessary chemical properties for the intended application. Overall, steel billets undergo a comprehensive inspection process that encompasses visual examination, dimensional verification, ultrasonic testing, magnetic particle inspection, and chemical analysis. This multi-faceted approach ensures that the billets meet the required quality standards and are suitable for use in production, thus minimizing the risk of any performance issues or failures during manufacturing processes.

- Q: What is the role of steel billets in the manufacturing of material handling equipment?

- Material handling equipment manufacturing relies heavily on steel billets, which are essential semi-finished steel products used as raw materials for various manufacturing processes. When it comes to material handling equipment, steel billets find their primary application in fabricating heavy-duty components like frames, beams, and brackets. These components must possess exceptional strength, durability, and resistance to wear and tear to endure the demanding conditions in which material handling equipment operates. Steel billets enable manufacturers to create these components with the necessary mechanical properties. Initially, the billets are heated and then shaped through processes such as rolling, forging, or extrusion to achieve the desired shape and dimensions. This shaping process ensures that the components have the required strength and structural integrity to handle the weight and stress associated with material handling tasks. In addition, steel billets offer excellent weldability, which is crucial for fabricating material handling equipment. The ability to securely and efficiently weld the components together ensures the safe and efficient movement of heavy loads, particularly in equipment like cranes, forklifts, and conveyors. Furthermore, steel billets provide a cost-effective solution for manufacturing material handling equipment. Steel is readily available, relatively affordable, and can be recycled, making it a sustainable choice. The versatility of steel billets also allows manufacturers to create components of various shapes and sizes, enabling customization to meet specific requirements. In conclusion, steel billets play a vital role in the manufacturing of material handling equipment. They provide the necessary raw material to create strong, durable, and reliable components that can withstand the demanding conditions of material handling tasks. With their excellent mechanical properties and weldability, steel billets contribute to the safe and efficient operation of material handling equipment.

Send your message to us

Prime Square Steel Billet 150x150mm 165x165mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19684 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords