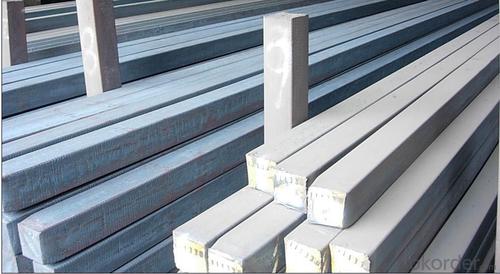

Prime square alloy steel billet 130mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 130mm Q235

Description of Prime square alloy steel billet 130mm Q235

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

Main Feature of Prime square alloy steel billet 130mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 130mm Q235

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Specifications of Prime square alloy steel billet 130mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 130mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: How are steel billets used in the production of electrical transmission towers?

- Steel billets play a crucial role in the manufacturing of electrical transmission towers. These billets are semi-finished steel products that are cast into a specific shape and size. When it comes to transmission towers, steel billets are used as raw material to create the tower structures. The process begins by carefully selecting high-quality steel billets and inspecting them for their chemical composition and physical properties. Once the billets meet the required specifications, they undergo heating and are passed through a series of rolling mills to achieve the desired shape and size of the tower sections. To make the steel billets malleable, they are heated to a specific temperature. This heating process reduces internal stresses and enhances the steel's ductility. The heated billets are then shaped into various sections such as angles, channels, and I-beams by passing them through multiple rolling stands. These sections are further cut into appropriate lengths and welded together to form the framework of the transmission tower. The steel billets provide the necessary strength and structural integrity to withstand the weight of the tower and environmental loads like wind and ice. In addition, the use of steel billets ensures excellent corrosion resistance, as steel is known for its durability and longevity. This is crucial for maintaining the reliability and safety of the power transmission infrastructure. In conclusion, steel billets are vital in the production of electrical transmission towers as they provide the raw material necessary for manufacturing the tower structures. Their strength, durability, and corrosion resistance make them an ideal choice for constructing towers that can support transmission lines and ensure efficient and reliable distribution of electricity.

- Q: How are steel billets used in the production of valves?

- Steel billets are used in the production of valves as a raw material. They are melted and then shaped into the desired shape and size of the valve through various manufacturing processes such as forging, machining, and heat treatment. The steel billets provide the necessary strength and durability required for valves to withstand high pressure and temperature conditions.

- Q: How are steel billets used in the production of agricultural equipment?

- The versatility and durability of steel billets make them indispensable in the production of agricultural equipment. These semi-finished steel products come in solid rectangular forms, making them perfect for various manufacturing processes. When it comes to agricultural equipment production, steel billets serve as the primary raw material for forging, casting, or rolling. Forging involves heating the billets to a specific temperature and shaping them with a hammer or press. This method is commonly used to create robust components like plowshares, tiller blades, and harrow teeth that require superior strength and resistance to wear. Casting, on the other hand, involves pouring molten steel into a mold and allowing it to solidify. By melting and casting steel billets into intricate shapes, manufacturers can produce complex components such as tractor engine blocks, combine harvester parts, and agricultural machinery frames. This flexibility in shape allows for customized equipment that meets specific requirements. Rolling is yet another technique that utilizes steel billets in agricultural equipment production. The billets are heated and then passed through rollers to reduce their size and shape them into bars, rods, or sheets. Rolled steel billets are commonly used for manufacturing axles, shafts, and brackets, which are crucial for the proper functioning of agricultural machinery. The inherent strength and durability of steel billets make them highly preferred in agricultural equipment production. The demanding conditions of the agricultural industry require machinery that can withstand harsh environments, heavy loads, and repetitive use. Steel billets offer exceptional strength, enabling the creation of equipment that can endure these challenging conditions. Furthermore, heat treatment processes like quenching and tempering can further enhance the mechanical properties of steel billets. In conclusion, steel billets play a crucial role in the production of agricultural equipment. Their versatility and durability allow manufacturers to create components and machinery that can withstand the challenging conditions of the agricultural industry. Whether used in forging, casting, or rolling, steel billets provide the necessary strength and reliability for efficient and long-lasting agricultural equipment.

- Q: How do steel billets contribute to the overall aesthetics of a structure?

- Steel billets, which are semi-finished steel products, do not directly contribute to the overall aesthetics of a structure. However, they play a crucial role in the manufacturing process of various steel components such as beams, columns, and decorative elements. These components, when properly designed and incorporated into a structure, can enhance its aesthetic appeal by providing strength, durability, and architectural uniqueness.

- Q: What are the different types of steel billet packaging?

- There are several different types of steel billet packaging that are commonly used in the industry. 1. Bundles: Bundles are one of the most common types of packaging for steel billets. In this method, several billets are tightly bound together using steel straps or wire rods. This helps to secure the billets and prevent any movement or damage during transportation or storage. 2. Wooden crates: Wooden crates are another popular packaging option for steel billets. These crates are usually made of sturdy wooden materials and are designed to provide maximum protection to the billets. They are typically reinforced with steel bands or straps to ensure the billets remain secure. 3. Steel cages: Steel cages or racks are commonly used for packaging steel billets. These cages are made of steel and are designed to hold multiple billets at once. They provide a sturdy and secure packaging solution and allow for easy handling and transportation. 4. Plastic wrapping: In some cases, steel billets may be wrapped in plastic film or shrink wrap to provide protection against moisture and corrosion. This method is often used when the billets are being stored or transported in a controlled environment. 5. Custom packaging: Depending on specific requirements, steel billets may also be packaged in custom-made containers or packaging solutions. These can include specialized crates, boxes, or containers designed to fit the dimensions and weight of the billets, ensuring maximum protection during transportation and storage. Overall, the choice of steel billet packaging depends on factors such as the size and weight of the billets, transportation method, and desired level of protection. Each type of packaging has its own advantages and is chosen based on the specific needs of the industry and the customer.

- Q: How are steel billets manufactured?

- Steel billets are manufactured through a process called continuous casting, where liquid steel is poured into a water-cooled mold to form a solidified billet shape. This billet is then further processed through reheating, rolling, and cooling to achieve the desired dimensions and properties.

- Q: How are steel billets used in the production of hydraulic cylinders?

- Hydraulic cylinders rely on steel billets as a crucial raw material for their production. These billets, which are cylindrical and made of high-quality steel, serve as the starting point for the manufacturing process. To begin, the steel billets are heated in a furnace. This heating process, known as hot rolling, makes the billets more malleable and easier to work with. Once heated, the billets are then passed through a series of rollers, shaping and elongating them to the desired size and form. After the initial shaping, the billets undergo further processing through various machining operations. These operations include drilling, boring, milling, and grinding, among others. By using these machining processes, the necessary features and dimensions for hydraulic cylinders, such as piston and rod bores, mounting holes, and fluid flow ports, are created. Once the machining operations are complete, the billets are subjected to heat treatment to improve their mechanical properties. The specific heat treatment method, either quenching and tempering or annealing, depends on the hydraulic cylinder's requirements. Heat treatment enhances the steel's strength, hardness, and durability, ensuring that the hydraulic cylinder can withstand the high pressures and forces it will encounter during operation. After shaping, machining, and heat treatment, the steel billets are ready for the final assembly stage. Other components, such as pistons, rods, seals, and valves, are added to complete the hydraulic cylinder. These components are carefully integrated with the billets to ensure proper functionality and reliable performance. In conclusion, steel billets are essential for the production of hydraulic cylinders. They undergo heating, shaping, machining, heat treatment, and assembly to form the core structure of the cylinder. This guarantees that the hydraulic cylinder possesses the necessary strength, durability, and precision required for efficient operation in a variety of industrial and mobile applications.

- Q: What are the different surface treatments for improved corrosion resistance in steel billets?

- There are several different surface treatments that can be applied to steel billets in order to improve their corrosion resistance. These treatments are designed to create a protective barrier on the surface of the steel, preventing the corrosive agents from reaching the underlying metal. Some common surface treatments for improved corrosion resistance in steel billets include: 1. Hot-dip galvanizing: This process involves immersing the steel billets in a bath of molten zinc. The zinc reacts with the steel to form a protective layer of zinc-iron alloy, known as a galvanized coating. This coating provides excellent corrosion resistance and can extend the lifespan of the steel billets. 2. Electroplating: Electroplating is a process in which a thin layer of metal, such as zinc or nickel, is deposited onto the surface of the steel billets using an electric current. This creates a protective barrier that prevents corrosion and provides a decorative finish. 3. Powder coating: Powder coating involves applying a dry powder to the surface of the steel billets and then heating it to form a protective layer. The powder is typically made of a mixture of resin and pigment, which melts and bonds to the steel when heated. Powder coating provides excellent corrosion resistance and is available in a wide range of colors and finishes. 4. Paint coatings: Painting steel billets with corrosion-resistant paint is another effective surface treatment. The paint forms a protective barrier that prevents moisture and corrosive agents from reaching the steel. Multiple layers of paint may be applied to improve the durability and longevity of the coating. 5. Passivation: Passivation is a chemical process that removes free iron and other contaminants from the surface of the steel billets. This helps to prevent the formation of corrosion and promotes the formation of a protective oxide layer. Passivation is often used in combination with other surface treatments, such as electroplating or powder coating, to enhance their corrosion resistance. It is worth noting that the choice of surface treatment for improved corrosion resistance in steel billets depends on various factors such as the environment in which the billets will be used, the desired lifespan of the steel, and the cost considerations. Therefore, it is essential to carefully evaluate the specific requirements and consult with experts to determine the most suitable surface treatment.

- Q: How are steel billets used in the construction industry?

- Steel billets are a crucial component in the construction industry, used in a variety of ways to support and enhance the structural integrity of buildings and infrastructure. These billets, which are essentially semi-finished steel products, are first heated and then shaped into specific forms to meet the desired requirements of construction projects. One of the primary applications of steel billets is in the production of reinforcing bars, commonly known as rebar. Rebar is used to provide strength and stability to concrete structures, such as buildings, bridges, and highways. Steel billets are heated and rolled into long, cylindrical shapes to create these reinforcement bars. Once embedded within the concrete, rebar enhances its tensile strength, preventing cracks and structural failure. Steel billets are also used in the manufacturing of structural steel sections, such as beams, columns, and channels. These sections are vital for constructing the skeleton of a building, providing support and load-bearing capacity. Steel billets are heated and rolled into various shapes and sizes, depending on the specific requirements of the project. These structural steel sections are then assembled to create the framework of the building, ensuring its stability and durability. In addition to rebar and structural steel sections, steel billets are utilized in the production of various other construction components. These include steel plates, pipes, tubes, and wires, which are used for different purposes within the construction industry. For instance, steel plates are used to reinforce the foundations of buildings, while steel pipes and tubes are used for plumbing, drainage, and HVAC systems. Steel wires are commonly used to strengthen concrete structures and as reinforcement in precast concrete elements. Overall, steel billets play a crucial role in the construction industry by providing the necessary raw material for the production of reinforcing bars, structural steel sections, and other construction components. Their versatility and strength make them an essential ingredient in ensuring the safety, stability, and longevity of buildings and infrastructure projects.

- Q: What are the different finishing processes used for steel billets?

- There are several different finishing processes used for steel billets to achieve the desired surface quality and dimensions. These processes include: 1. Hot rolling: This process involves passing the steel billets through a series of heated rollers to reduce their thickness and shape them into the desired profile. It can be used to produce a variety of finished products, such as bars, rods, and structural shapes. 2. Cold drawing: In this process, the steel billets are pulled through a series of dies at room temperature to reduce their cross-sectional area and improve their surface finish. Cold drawing is commonly used to produce high-quality steel bars and wires with precise dimensions and a smooth surface. 3. Peeling: Peeling is a machining process in which a thin layer of material is removed from the surface of the steel billets using a cutting tool. This process helps to improve the surface finish, remove any defects, and achieve tight dimensional tolerances. 4. Grinding: Grinding involves using an abrasive wheel or belt to remove material from the surface of the steel billets. It is commonly used to remove surface defects, such as scale and rust, and to achieve a smooth and uniform surface finish. 5. Polishing: Polishing is a finishing process that involves using abrasive materials, such as polishing compounds and buffing wheels, to create a smooth and reflective surface on the steel billets. It is often used to enhance the aesthetic appeal of the finished product and improve its resistance to corrosion. 6. Coating: Coating is a process in which a protective layer is applied to the surface of the steel billets to improve their resistance to corrosion and other environmental factors. Common coating methods include galvanizing, where a layer of zinc is applied to the surface, and painting, where a layer of paint or other protective material is applied. Overall, these finishing processes are essential in ensuring that steel billets meet the required specifications and standards for their intended applications. They help to improve the surface finish, dimensional accuracy, and overall quality of the finished steel products.

Send your message to us

Prime square alloy steel billet 130mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords