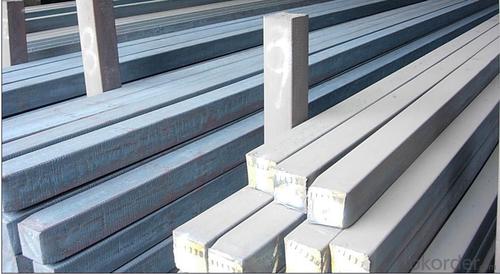

Prime quality square alloy steel billet 135mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime quality square alloy steel billet 135mm Q235

Description of Prime quality square alloy steel billet 135mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime quality square alloy steel billet 135mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime quality square alloy steel billet 135mm Q235

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Prime quality square alloy steel billet 135mm Q235

Product | Prime quality square alloy steel billet 135mm Q235 |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime quality square alloy steel billet 135mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel billets be used in the production of construction machinery?

- Construction machinery can indeed be produced using steel billets. Steel billets, which are partially finished steel products, can be further processed into various shapes and sizes, including components for construction machinery. These billets can be hot-rolled or cold-rolled to create different types of steel products commonly used in construction, such as bars, rods, plates, or sheets. Steel's exceptional strength and durability make it an excellent material for construction machinery, as it can withstand heavy loads, resist corrosion, and provide structural integrity. Consequently, steel billets play a vital role as raw materials in the manufacture of construction machinery.

- Q: Are steel billets used in the manufacturing of tools?

- Yes, steel billets are commonly used in the manufacturing of tools. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes, including bars, rods, and sheets. These billets serve as the primary raw material in tool manufacturing, as they provide the necessary strength, durability, and machinability required for producing high-quality tools. By shaping and machining the steel billets, manufacturers can create a wide range of tools such as wrenches, hammers, screwdrivers, drill bits, and cutting tools. The use of steel billets ensures that these tools possess the necessary hardness, toughness, and resistance to wear and tear, making them reliable and long-lasting. Therefore, steel billets play a crucial role in the production of tools, contributing to the overall efficiency and functionality of various industries.

- Q: Can steel billets be used for structural purposes?

- Structural purposes can indeed be served by steel billets. These particular steel products are considered semi-finished and are typically shaped through hot-rolling or forging techniques to create various structural components such as beams, columns, and more. Their utilization in construction and engineering projects is widespread due to their ability to provide strength, durability, and the capability to bear heavy loads. Before being incorporated into the construction process, these billets are often further processed and shaped according to specific design requirements. The construction industry heavily relies on steel billets for the construction of buildings, bridges, highways, and other infrastructure projects due to their exceptional mechanical properties and high strength-to-weight ratio. Moreover, their suitability for various structural applications is enhanced by their ease of welding.

- Q: What is carbon accumulation?

- Generally refers to the polycarbonate, PC, is a kind of thermoplastic plastics, good transparency, good mechanical properties, surface hardness, common uses such as CD, plastic glasses, a fence, protective window, public places, vacuum cleaners, coffee machine, juicer barrel, refrigerator shelf, pure such as the bucket.

- Q: What is the weight of a standard steel billet?

- The weight of a standard steel billet can vary depending on its dimensions, but typically ranges from 1 to 6 metric tons.

- Q: What is the role of steel billets in the manufacturing of automotive suspension systems?

- The role played by steel billets in the manufacturing of automotive suspension systems is crucial. These systems are responsible for ensuring a comfortable and smooth ride while maintaining the stability and handling of the vehicle. Various components of the suspension system, including control arms, coil springs, sway bars, and stabilizer links, are fabricated using steel billets as the raw material. Strength and durability are primary requirements for suspension systems, and steel billets are an ideal choice for manufacturing suspension components due to their high tensile strength and excellent mechanical properties. Carbon steel is commonly used to make these billets because of its exceptional strength and ability to withstand the heavy loads and forces encountered by suspension systems. The process of manufacturing suspension components from steel billets involves several stages. Initially, the billets are heated to a specific temperature, typically above their recrystallization temperature, to make them more malleable. This enables the material to be easily shaped and formed into the desired component. After heating, the billets undergo various forming processes such as hot forging, cold forging, or machining, depending on the specific component being manufactured. These processes help shape the billets into control arms, coil springs, or other suspension components with precise dimensions and specifications. The use of steel billets in suspension systems offers several advantages. Firstly, steel is a cost-effective material, making the overall manufacturing process more economical. Moreover, steel provides an excellent strength-to-weight ratio, allowing for lighter suspension components without compromising on strength and durability. This, in turn, contributes to improved fuel efficiency and overall vehicle performance. Additionally, steel billets have high resistance to wear, corrosion, and fatigue, ensuring that the suspension components can endure harsh operating conditions and have a long lifespan. They also possess excellent damping characteristics, which help absorb and dissipate vibrations and shocks, further enhancing the comfort and stability of the vehicle. In conclusion, steel billets play a crucial role in the manufacturing of automotive suspension systems. Their strength, durability, and malleability make them an ideal raw material for fabricating various suspension components. By utilizing steel billets, automotive manufacturers can produce suspension systems that provide a smooth ride, stability, and enhanced performance, contributing to the overall comfort and safety of drivers and passengers.

- Q: What are the market trends and growth prospects for steel billets?

- The market trends for steel billets indicate steady growth prospects. With the increasing demand for steel in various sectors such as construction, automotive, and infrastructure, the demand for steel billets is expected to rise. Additionally, the growing focus on sustainable and eco-friendly construction materials is likely to drive the market further. Furthermore, the expanding urbanization and industrialization in emerging economies present significant growth opportunities for the steel billets market. Overall, the market for steel billets is expected to experience positive growth in the coming years.

- Q: Are steel billets subject to any regulations or certifications?

- Steel billets must adhere to numerous regulations and certifications to guarantee their production, quality, and safety standards are met. The ISO 9001 certification, an internationally recognized standard for quality management systems, is one of the most common certifications for steel billets. This certification ensures that the manufacturing process of steel billets follows consistent quality control measures, from sourcing raw materials to final production. Steel billets may also need to obtain industry-specific certifications, depending on their intended use. For example, if the steel billets are intended for construction projects, they must comply with certifications such as ASTM standards or European EN standards. These certifications define the necessary mechanical properties, chemical composition, and other specifications that steel billets must meet to ensure they are suitable for construction purposes. In addition, governmental bodies or industry associations may impose regulations on steel billets. These regulations can include safety standards, environmental regulations, and compliance with trade policies. For instance, steel billet producers may need to comply with regulations regarding emissions, waste management, or occupational health and safety. In conclusion, various regulations and certifications are in place to ensure the quality, safety, and compliance with industry standards of steel billets. These certifications and regulations are crucial for maintaining the integrity of steel billets and ensuring they are suitable for various applications.

- Q: What is the role of steel billets in the construction of residential buildings?

- Residential building construction heavily relies on steel billets, which have a crucial function. These elongated steel bars, with their rectangular shape, act as the primary raw material for producing different structural components used in the construction process. One major application of steel billets lies in the creation of reinforced concrete structures. Due to its exceptional strength and durability, reinforced concrete finds extensive use in building foundations, columns, beams, and slabs. To enhance the structural integrity of the building and provide tensile strength, steel billets are employed in the manufacturing of rebar. This rebar is then embedded within the concrete, allowing the building to withstand external forces like wind, seismic activity, and its own weight. Moreover, steel billets find utility in the production of steel beams and columns. These components play a crucial role in supporting the building's weight and transferring loads from the upper floors to the foundation. Steel beams offer superior strength and rigidity, enabling the construction of open and spacious interiors without the need for excessive support walls. This not only provides design flexibility but also maximizes the usable space within residential buildings. Steel billets also contribute to the construction of stairs, handrails, and balconies. These architectural elements necessitate materials with high strength to ensure the structure's safety and longevity. By providing the necessary strength and stability, steel billets enable safe and secure access to different areas of the building. In conclusion, steel billets are of utmost importance in residential building construction, serving as the raw material for various structural components. From reinforced concrete structures to steel beams, columns, and other architectural elements, steel billets play a vital role in ensuring the strength, durability, and overall safety of residential buildings.

- Q: What are the different types of steel billets used in the aerospace industry?

- Various types of steel billets are utilized in the aerospace industry to meet the stringent requirements for aircraft components. Rigorous testing and quality control are undertaken on these steel billets to ensure they meet the necessary standards for aerospace applications. 1. Stainless Steel Billets: Stainless steel proves to be highly resistant to corrosion, making it an ideal choice for aircraft parts that are exposed to moisture, high temperatures, and chemicals. It possesses excellent mechanical properties, including high strength and toughness, which are essential for aerospace components. 2. Alloy Steel Billets: Alloy steel combines iron with other elements, such as nickel, chromium, and molybdenum, to enhance specific properties. These billets offer outstanding strength, hardness, and wear resistance, making them suitable for critical parts like landing gear, engine components, and structural elements. 3. Tool Steel Billets: Tool steel is renowned for its exceptional hardness, toughness, and high temperature resistance. It is commonly used in the aerospace industry for manufacturing cutting tools, dies, and molds. The ability to retain its hardness at elevated temperatures makes tool steel billets crucial for machining and shaping aerospace components. 4. Carbon Steel Billets: Due to its high strength, low cost, and ease of manufacturing, carbon steel is widely utilized in the aerospace industry. It primarily finds application in non-critical parts such as brackets, fasteners, and supports. Carbon steel billets can be further classified based on their carbon content, with higher carbon steel providing greater strength but reduced ductility. 5. Titanium Steel Billets: Titanium alloys are extensively employed in the aerospace industry due to their exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance. These billets offer excellent mechanical properties while being lightweight, making them ideal for critical components like aircraft frames, engine parts, and landing gear. It is essential to consider factors such as strength, weight, corrosion resistance, temperature resistance, and cost when selecting steel billets for aerospace components. The choice of steel billets plays a crucial role in ensuring the safety, performance, and longevity of the aircraft components.

Send your message to us

Prime quality square alloy steel billet 135mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords