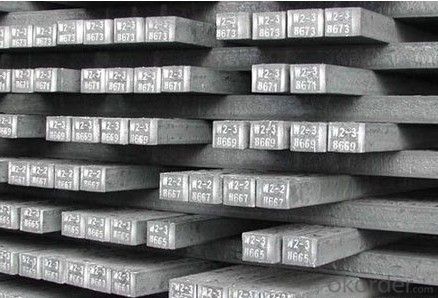

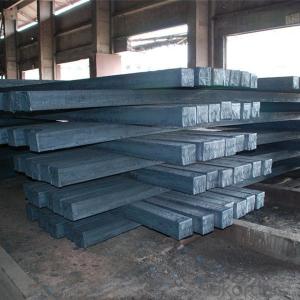

Square Shape Hot Rolled Mild Steel Billet 60mm-150mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Shape Hot Rolled Mild Steel Billet 60mm-150mm at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Square Shape Hot Rolled Mild Steel Billet 60mm-150mmare ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Square Shape Hot Rolled Mild Steel Billet 60mm-150mm are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195/Q235/Q275/20MnSi

Certificates: ISO, SGS, BV

size:60*60/90*90/100*100/120*120/150*150

Length: 6m/12m,

Packaging: Export packing, nude packing, bundled

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: How do steel billets contribute to the overall vibration resistance of a product?

- Steel billets are an essential component in enhancing the overall vibration resistance of a product. The high-strength properties of steel make it an ideal material for reducing vibrations and improving product stability. Steel billets are typically used as a raw material in the manufacturing process, where they are further processed into various shapes and forms. The dense and uniform structure of steel billets allows them to absorb and dissipate vibration energy effectively. When integrated into a product, steel billets provide additional mass, which helps dampen vibrations by absorbing and distributing the energy throughout the structure. This mass acts as a stabilizing force, preventing excessive movement and reducing the amplitude of vibrations. Moreover, steel billets possess excellent mechanical properties, such as high tensile strength and stiffness, which contribute to the overall vibration resistance of a product. These properties enable steel billets to withstand dynamic forces and resist deformation under vibration, ensuring the structural integrity of the product. Additionally, steel billets can be engineered to have specific geometries and cross-sectional shapes that further enhance their vibration resistance. For example, the use of round or square billets with smooth surfaces minimizes stress concentration points and reduces the risk of fatigue failure. By optimizing the design and dimensions of steel billets, manufacturers can tailor the vibration resistance of a product to meet specific requirements. In summary, steel billets play a crucial role in improving the overall vibration resistance of a product. Their high mass, dense structure, and superior mechanical properties enable them to absorb and dissipate vibration energy, stabilize the product, and enhance its structural integrity. By utilizing steel billets in the manufacturing process, manufacturers can ensure that their products are more resistant to vibrations, leading to improved performance and longevity.

- Q: Can steel billets be used in the production of oil and gas equipment?

- Steel billets have the capability to be utilized in the manufacturing process of oil and gas equipment. These semi-finished metal products, known as steel billets, are frequently employed as raw materials for the production of various industrial goods, including oil and gas equipment. They can undergo further treatment through hot rolling or forging to create distinct components like pipes, valves, flanges, and fittings, all of which are vital for the oil and gas industry. Given its robustness and resilience, steel is an ideal material for enduring the demanding conditions and high pressures encountered in oil and gas operations. Moreover, steel billets can be tailored to meet specific requirements, such as corrosion resistance, heat resistance, and mechanical properties, ensuring that the final product is suitable for its intended application within the oil and gas sector.

- Q: Can steel billets be forged?

- Yes, steel billets can be forged.

- Q: What are the main factors affecting the machinability of alloy steel billets?

- The main factors affecting the machinability of alloy steel billets include the composition of the alloy steel, the heat treatment it has undergone, the hardness of the material, the presence of impurities or inclusions, and the cutting parameters used during machining such as cutting speed, feed rate, and depth of cut.

- Q: Are steel billets used in the manufacturing of industrial machinery?

- Yes, steel billets are commonly used in the manufacturing of industrial machinery. Steel billets are semi-finished products that are typically produced through a process called continuous casting. These billets serve as the raw material for various types of machinery, including heavy-duty equipment, construction machinery, and machine tools. Steel is a preferred choice for industrial machinery due to its strength, durability, and resistance to wear and tear. Steel billets are often used as the starting material for forging, rolling, or machining processes to create the specific components required for industrial machinery. These components can include gears, shafts, frames, brackets, and other structural parts. The high-quality properties of steel, such as its high tensile strength and excellent mechanical properties, make it an ideal material for withstanding the demanding conditions and heavy loads that industrial machinery is subjected to. Additionally, steel's ability to be easily welded and machined allows manufacturers to produce complex and precise parts for industrial machinery. Overall, steel billets play a crucial role in the manufacturing of industrial machinery, providing the necessary raw material to create strong and reliable components that can withstand the rigors of various industrial applications.

- Q: Can steel billets be used for making tools?

- Yes, steel billets can be used for making tools. Steel billets are raw metal blocks that can be further processed and shaped into various tools through techniques like forging, machining, and heat treatment. The high strength and durability of steel make it an ideal material for tool manufacturing, as it provides the necessary hardness, toughness, and resistance to wear and tear.

- Q: What are the market trends and growth prospects for steel billets?

- Steel billets play a vital role in the steel industry as they serve as the primary material for various downstream applications. The growth and market trends of steel billets are greatly influenced by factors like global economic growth, infrastructure development, and the demand for steel in different sectors. One notable market trend for steel billets is the increasing demand from the construction industry. With the rapid urbanization and infrastructure development in emerging economies, there is a rising need for steel-intensive construction projects. Steel billets are extensively used in the construction of bridges, buildings, and other infrastructure projects, which drives the demand for this product. Another market trend is the growing demand for steel billets in the automotive industry. The automotive sector is a major consumer of steel, and as the industry shifts towards lightweight and high-strength materials, the demand for steel billets is expected to increase. Steel billets are used in the production of various automotive components, including engine parts, chassis, and suspension systems. Furthermore, the increasing focus on renewable energy sources such as wind and solar power is expected to drive the demand for steel billets. Steel components are required for wind turbines and solar panel structures, and as renewable energy projects expand globally, the demand for steel billets is likely to experience significant growth. In terms of growth prospects, the steel billets market is expected to witness steady growth in the coming years. The Asia-Pacific region, particularly China and India, is projected to dominate the market due to their robust construction and infrastructure sectors. These countries have extensive urbanization projects and ongoing infrastructure development plans, which will contribute to the demand for steel billets. Additionally, the recovery of the global economy after the COVID-19 pandemic is expected to boost the demand for steel billets. As economies bounce back and industrial activities regain momentum, the demand for steel in various sectors, including construction, automotive, and energy, will increase, positively impacting the steel billets market. However, it is important to note that market trends and growth prospects for steel billets can be influenced by factors like fluctuations in raw material prices, trade policies, and environmental regulations. Furthermore, the increasing adoption of alternative materials such as aluminum and composites in certain applications may pose a challenge to the growth of the steel billets market. In conclusion, the market trends for steel billets are driven by the demand from the construction, automotive, and renewable energy sectors. The growth prospects for this market are promising, particularly in the Asia-Pacific region as economies recover from the pandemic and infrastructure projects gain momentum. Nevertheless, challenges such as fluctuations in raw material prices and competition from alternative materials should also be taken into consideration.

- Q: How are steel billets used in the manufacturing of oil and gas equipment?

- Steel billets are used in the manufacturing of oil and gas equipment by being shaped and formed into various components such as pipes, valves, and fittings. These billets are heated and then forged, molded, or rolled to create the required shapes and dimensions. The resulting steel components possess high strength, durability, and corrosion resistance, making them suitable for the harsh conditions encountered in the oil and gas industry.

- Q: How are steel billets used in the manufacturing of pumps and compressors?

- Pumps and compressors rely heavily on steel billets, a crucial raw material for their manufacturing process. These semi-finished steel forms are transformed into different components and parts of these devices. To prepare steel billets for shaping, the initial step involves heating them to a high temperature to make them malleable. Once heated, the billets go through various metalworking techniques like forging, rolling, or extrusion. By subjecting them to these processes, the billets are converted into the desired shapes and sizes required for specific pump and compressor components. In pump manufacturing, steel billets are utilized to fabricate impellers, responsible for fluid movement and circulation. The billets are shaped according to the impeller design through machining or casting procedures. Similarly, for compressors, steel billets are used to create vital components like cylinders, pistons, and connecting rods, which facilitate gas compression and movement. The preference for steel billets in pump and compressor manufacturing stems from their advantageous properties, such as strength, durability, and corrosion resistance. These properties are vital for ensuring the efficiency and longevity of these mechanical devices, especially when they operate under high pressures, temperatures, and harsh working conditions. In conclusion, steel billets play a fundamental role in the manufacturing process of pumps and compressors. They provide the necessary raw material for shaping and creating various components that enable these devices to function effectively.

- Q: What is the role of steel billets in the construction of residential buildings?

- Steel billets are an essential component in the construction of residential buildings as they serve as the raw material for manufacturing various structural steel elements. These billets are heated, shaped, and transformed into different forms such as beams, columns, and reinforcing bars, which provide strength and stability to the building's framework. Additionally, steel billets are also used in the fabrication of other critical components like wall panels and roof trusses, ensuring durability and safety in residential construction.

Send your message to us

Square Shape Hot Rolled Mild Steel Billet 60mm-150mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords