Prime square alloy steel billet 95mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

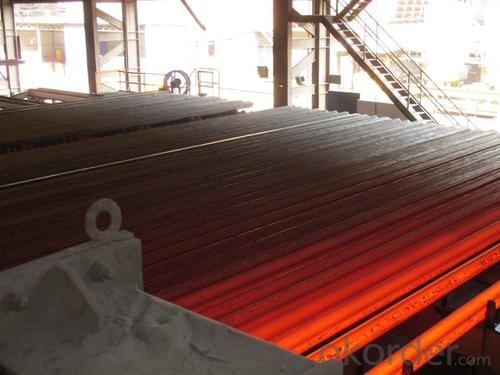

Structure of Prime square alloy steel billet 95mm Q235

Description of Prime square alloy steel billet 95mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime square alloy steel billet 95mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 95mm Q235

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Specifications of Prime square alloy steel billet 95mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 95mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: What are the different methods of steel billet inspection?

- There are several different methods of steel billet inspection that are commonly used in the manufacturing industry. These methods are employed to ensure the quality and integrity of the steel billets before they are further processed into various end products. Some of the most common methods of steel billet inspection include: 1. Visual Inspection: This is the simplest and most basic method of inspection, where trained inspectors visually examine the billets for any surface defects, such as cracks, pits, or any other irregularities. This method is typically used as an initial screening process before more advanced inspection techniques are employed. 2. Ultrasonic Testing: Ultrasonic testing utilizes high-frequency sound waves to detect any internal defects or inconsistencies within the steel billets. This method involves the use of a transducer that emits sound waves into the billet, and the reflected waves are analyzed to identify any flaws or abnormalities. Ultrasonic testing is effective in detecting internal defects like voids, inclusions, or cracks. 3. Magnetic Particle Inspection: This method is particularly useful for detecting surface and near-surface defects in steel billets. It involves applying a magnetic field to the billet and then applying iron particles to the surface. The particles will cluster around any magnetic leakage caused by surface cracks or defects, making them easily visible to the inspector. 4. Eddy Current Testing: Eddy current testing is a non-destructive method used to detect surface and near-surface defects in conductive materials, including steel billets. It involves passing an alternating current through a coil, creating an electromagnetic field. Any changes in the electromagnetic field caused by defects in the billet's surface are detected and analyzed, allowing for the identification of flaws. 5. X-ray Inspection: X-ray inspection is a widely used method for inspecting steel billets. It involves passing X-rays through the billet and capturing the resulting image on a film or digital detector. This method is highly effective in detecting both internal and external defects, such as cracks, voids, inclusions, or segregation. These are just a few of the commonly employed methods of steel billet inspection. Each method has its advantages and limitations, and the choice of inspection technique depends on factors such as the type of defect being targeted, the size and shape of the billets, and the specific requirements of the end product. By utilizing a combination of these inspection methods, manufacturers can ensure the quality and reliability of the steel billets they produce.

- Q: What are the applications of steel billets in the automotive industry?

- Steel billets are an essential component in the automotive industry, playing a crucial role in various applications. One of the primary uses of steel billets in this industry is for the production of engine parts. The billets are forged and machined to create crankshafts, connecting rods, and camshafts, which are vital components for the proper functioning of an engine. Steel billets are also used in the manufacturing of suspension and steering components. These billets are shaped into various parts such as control arms, tie rods, and steering knuckles, which provide stability, control, and smooth handling to the vehicle. These components are crucial for ensuring a safe and comfortable driving experience. Furthermore, steel billets find applications in the production of transmission components. They are forged and machined to create gears, shafts, and other transmission parts that facilitate the smooth transfer of power from the engine to the wheels. These components play a significant role in the overall performance and efficiency of the vehicle. Additionally, steel billets are used in the manufacturing of chassis and frame components. By using billets, manufacturers can create strong and durable structures that provide stability and support to the entire vehicle. Chassis components such as cross members, brackets, and reinforcements are often made from steel billets to ensure the vehicle's structural integrity. In summary, steel billets are widely employed in the automotive industry for various applications. They are used to create engine parts, suspension and steering components, transmission parts, and chassis components. The use of steel billets in these applications ensures the durability, performance, and safety of vehicles.

- Q: What are the different types of cleaning methods used for steel billets?

- There are several different types of cleaning methods used for steel billets. These include mechanical cleaning methods such as shot blasting or wire brushing, chemical cleaning methods like pickling or acid cleaning, and thermal cleaning methods such as annealing or heat treatment. Each method is chosen based on the specific requirements and condition of the steel billets to ensure effective and efficient cleaning.

- Q: How are steel billets used in the production of forgings?

- Steel billets are used as the starting material in the production of forgings. They are heated and shaped using specialized machinery and techniques to create the desired shape and size of the final forged product. The billets provide the necessary strength and durability required for forging processes, ensuring the resulting forgings possess the desired mechanical properties.

- Q: What is the role of steel billets in the manufacturing of industrial boilers?

- Steel billets play a crucial role in the manufacturing of industrial boilers. These billets serve as the raw material from which the various components of the boiler are formed. Industrial boilers are complex structures that require high-quality, durable materials to withstand the harsh conditions they operate in. Steel billets are typically made from carbon steel or alloy steel, which possess excellent strength and corrosion resistance properties. These billets are first heated and then shaped into different forms, such as plates, tubes, or rods, through processes like rolling, extrusion, or forging. These formed components are then further processed and assembled to create the boiler. In the manufacturing process, steel billets are used to fabricate important boiler components, such as the shell, tubes, and flues. The shell, made from steel plates, provides the main body of the boiler, while the tubes and flues allow for the passage of hot gases and water. Steel billets ensure the structural integrity of these components, as they can withstand high temperatures and pressures without deforming or failing. Moreover, steel billets are also used to create other auxiliary components of industrial boilers, including supports, brackets, and fittings. These components are crucial for the proper functioning and installation of the boiler, ensuring stability, efficiency, and safety. Overall, steel billets are essential in the manufacturing of industrial boilers as they provide the necessary strength, durability, and versatility required to withstand the demanding conditions of operation. The use of high-quality steel billets ensures that the boilers are reliable, long-lasting, and capable of meeting the rigorous performance standards expected in industrial applications.

- Q: What are the main challenges in the supply chain management of steel billets?

- The main challenges in the supply chain management of steel billets include ensuring efficient transportation and logistics, managing inventory levels to avoid stockouts or excess inventory, dealing with fluctuating demand and production uncertainties, maintaining quality standards throughout the supply chain, and effectively collaborating with suppliers and customers to ensure timely delivery and customer satisfaction.

- Q: How are steel billets used in the production of hydraulic cylinders?

- Steel billets are an essential raw material used in the production of hydraulic cylinders. These billets are cylindrical in shape and made from high-quality steel. They serve as the starting point for the manufacturing process of hydraulic cylinders. The first step in utilizing steel billets is to heat them in a furnace. This heating process, known as hot rolling, allows the billets to become malleable and easier to work with. Once heated, the billets are then passed through a series of rollers, which shape and elongate them into the desired size and form. After the initial shaping, the billets are further processed through various machining operations. This includes drilling, boring, milling, and grinding, among others. These machining processes help create the necessary features and dimensions required for hydraulic cylinders, such as piston and rod bores, mounting holes, and ports for fluid flow. Once the machining operations are completed, the billets are subjected to heat treatment to enhance their mechanical properties. This involves either quenching and tempering or annealing, depending on the specific requirements of the hydraulic cylinder. Heat treatment helps improve the strength, hardness, and durability of the steel, ensuring that the hydraulic cylinder can withstand the high pressures and forces it will encounter during operation. Once the steel billets have been shaped, machined, and heat-treated, they are ready for the final assembly stage. At this point, other components such as pistons, rods, seals, and valves are added to complete the hydraulic cylinder. These components are carefully integrated with the billets to ensure proper functionality and reliable performance. In summary, steel billets play a crucial role in the production of hydraulic cylinders. They are heated, shaped, machined, heat-treated, and assembled to create the core structure of the cylinder. This ensures that the hydraulic cylinder possesses the necessary strength, durability, and precision required for its efficient operation in various industrial and mobile applications.

- Q: How are steel billets used in the manufacturing of gears and bearings?

- Steel billets are an essential raw material in the manufacturing process of gears and bearings. These billets are semi-finished steel products that are typically cast into a square or rectangular shape. They serve as the starting point for producing various components used in gears and bearings. In the case of gears, steel billets are first cut into smaller sections to create gear blanks or rough gear shapes. These blanks are then further processed through a series of operations like forging, machining, and heat treatment. Forging involves shaping the gear blank using compressive forces, which enhances the mechanical properties of the steel and aligns the grain structure for better strength. Machining is then used to remove excess material, refine the shape, and create the gear teeth. Finally, heat treatment is applied to improve the hardness, toughness, and wear resistance of the gear. Similarly, in the manufacturing of bearings, steel billets are transformed into various components such as inner and outer rings, balls or rollers, and cages. The billets are first cut and shaped into rough rings, which are then further processed through machining operations to achieve the desired dimensions and precision. The rings are often subjected to heat treatment to enhance their hardness, improve surface finish, and increase resistance to wear and fatigue. The balls or rollers are also produced from steel billets through a similar process, while cages are typically fabricated separately using sheet metal. Overall, steel billets play a crucial role in the manufacturing of gears and bearings. They serve as the foundation material that undergoes various shaping, machining, and heat treatment processes to create the final components with the required strength, durability, and precision. The quality of the steel billets used greatly influences the performance and longevity of gears and bearings, making them a critical aspect of the entire manufacturing process.

- Q: How are steel billets tested for mechanical properties?

- Various methods are employed to test the mechanical properties of steel billets in order to verify their quality and suitability for specific applications. One commonly used method is the tensile test, which involves extracting a small sample from the billet and subjecting it to an increasing tensile force until it breaks. This test aids in determining crucial mechanical properties such as ultimate tensile strength, yield strength, and elongation. Another approach utilized is the hardness test, which assesses the billet's surface resistance to indentation. This test provides information regarding the billet's hardness, which is essential for evaluating its ability to withstand wear and deformation. Moreover, the impact test is performed to evaluate the billet's toughness and capacity to absorb energy. This entails striking a standardized sample with a pendulum and measuring the energy absorbed during fracture. The impact test is particularly significant for applications where the steel billet is exposed to sudden loads or impacts. To evaluate the billet's ability to resist deformation, the compression test is employed. In this test, the billet is subjected to a compressive force until it deforms or breaks. The results obtained from this test assist in determining the billet's compressive strength and deformation characteristics. Additionally, non-destructive testing methods such as ultrasonic testing and magnetic particle inspection are utilized to identify any internal defects or irregularities in the billet. These methods involve the use of specialized equipment to examine the billet's internal structure and detect any flaws that may compromise its mechanical properties. In conclusion, steel billets undergo a comprehensive range of tests to ensure that their mechanical properties meet the necessary standards. These tests are crucial in guaranteeing the quality and dependability of the billets, enabling their use in various industries including construction, automotive, and manufacturing.

- Q: What are the different forging techniques used for steel billets?

- Steel billets can be forged using various techniques, each with its own benefits and results. Some commonly employed methods for forging steel billets are: 1. Open Die Forging: By placing the steel billet between two flat dies and applying compressive force, it can be shaped. This technique allows for the formation of a wide range of shapes and is often used for large and intricate components. 2. Closed Die Forging: Also known as impression die forging, this method utilizes specially shaped dies with impressions of the desired final shape. The steel billet is positioned between the dies and compressed to conform to the cavities. Closed die forging provides precise control over the shape and dimensions of the end product. 3. Roll Forging: Here, the steel billet is passed through rotating rolls that exert compressive force to shape it. Roll forging is commonly employed for the production of long cylindrical shapes like bars, rods, and shafts. 4. Upset Forging: This technique involves axial compression of the steel billet to increase its cross-sectional area and reduce its length. Upset forging is often used to create thicker sections or increase the material's diameter. 5. Press Forging: Hydraulic or mechanical presses are used in press forging to apply force to the steel billet, shaping it against the die. This method enables precise control over the forging process, making it suitable for intricate shapes or close tolerances. 6. Swaging: Swaging is a forging technique where the diameter of a steel billet is reduced by applying radial compressive force using a series of dies. This process is commonly employed to produce tapered or pointed components like pins, bolts, or needles. Each of these forging techniques offers unique advantages depending on the desired shape, size, and properties of the final product. The choice of forging technique is determined by factors such as part complexity, material properties, production volume, and cost considerations.

Send your message to us

Prime square alloy steel billet 95mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords