1/8 Aluminum Sheets - Mill Finish Aluminium Sheet AA1100 H14 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet AA1100 H14 for Building

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminium Sheet AA1100 H14 for Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet AA1100 H14 for Building

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

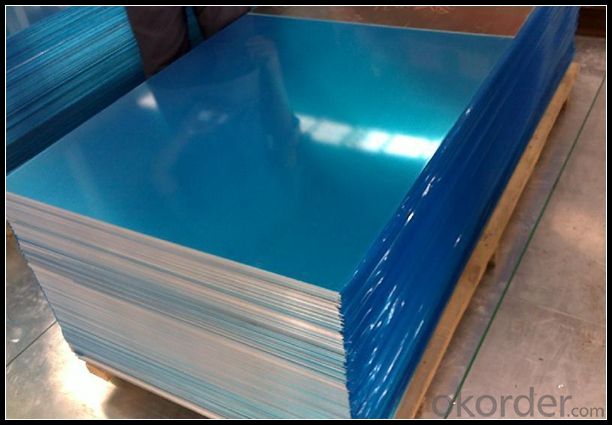

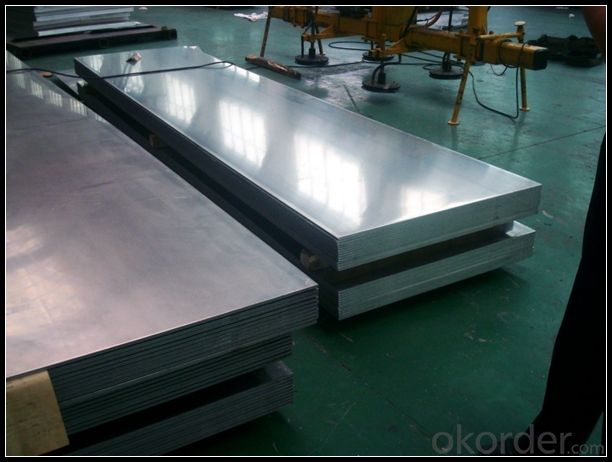

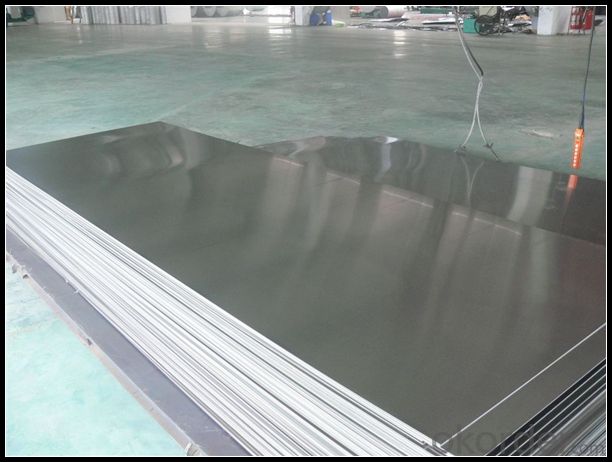

5. Image of Mill Finish Aluminium Sheet AA1100 H14 for Building

6. Package and shipping of Mill Finish Aluminium Sheet AA1100 H14 for Building

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the difference between aluminium plate 5A05 and 5A06?

- The aluminum plate doesn't have this material. Have you made a mistake?Give you a full one,1, pure aluminum: Material: 1050/1060/1070/1100/ 1200/ thickness: 0.1---20mm width: 800---2200mm2, alloy aluminum: Material: 2A21/3003/5052/5083/6061/6082 /8011 thickness: 0.5---260mm width: 800---2800mm3 curtain wall Kaiping aluminum plate: Material: 1060/1100 thickness 0.95, 1.35, 1.85, 2.35, 2.7, 2.85mm, width 0.8---1.5m

- Q: aluminum is used to make planes, cast iron is used to make heavy mashines. what is the comparisonof teh densities of aluminum and cast iron?

- The density of aluminum is MUCH lower than cast iron (thus, aluminum is LIGHTER). Because it is lighter, it would be much more ideal for applications like plane building, which is why aluminum is used over cast iron in airplanes. As well, aluminum has a protective coating called aluminum oxide which protects it from corroding in water. [Answer: see above]

- Q: Which kind of glue is best for bonding aluminum sheets?

- I advice you to use AB glue to bond aluminum sheets, acylic acid AB glue is better than 502 in bonding aluminum sheets, Gelianghao XSSS-290AB glue sold in hardware store can directly permeate into the surface of aluminum sheets and bond the sheets tightly.

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a versatile material that offers several advantages for facade applications. It is lightweight, durable, and corrosion-resistant, making it suitable for various weather conditions. Aluminum sheets can be easily fabricated and installed, offering flexibility in design and allowing for intricate and complex facades. Additionally, aluminum can be finished in a variety of ways, including powder coating, anodizing, or painting, to enhance its appearance and provide the desired aesthetic appeal. Overall, the use of aluminum sheets for architectural facades provides architects and designers with a wide range of options to create visually appealing and long-lasting building exteriors.

- Q: What is the weight of an aluminum sheet?

- The weight of an aluminum sheet can vary depending on its thickness and dimensions.

- Q: Trying to find the best aluminum powder I can buy for rocket engines and pyrotechnic (fireworks) uses?

- For okorder (I think there prices are the same as the other high end brands, except Star Molecule is not diluted, and it works better from my experience).

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Yes, aluminum sheets are suitable for aircraft manufacturing. Aluminum is widely used in the aerospace industry due to its unique combination of properties such as lightweight, high strength, corrosion resistance, and excellent formability. These characteristics make aluminum an ideal material for constructing various aircraft components, including fuselages, wings, and structural parts. Additionally, aluminum alloys can be easily joined, allowing for efficient manufacturing processes. Overall, aluminum sheets play a crucial role in aircraft manufacturing, contributing to the overall performance, durability, and safety of the aircraft.

- Q: What are the different packaging options available for aluminum sheets during transportation?

- There are several packaging options available for aluminum sheets during transportation. Some common methods include wrapping the sheets in protective film or paper, using wooden crates or pallets to stack and secure the sheets, and using cardboard or plastic edge protectors to prevent damage. Additionally, aluminum sheets can also be packaged in custom-cut foam or bubble wrap for added cushioning and protection during transit.

- Q: Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are several different types of alloys used for powder-coated aluminum sheets, each with its own unique set of properties and characteristics. Some of the most commonly used alloys include: 1. 3003 Alloy: This alloy is one of the most widely used for powder-coated aluminum sheets. It offers good corrosion resistance, excellent formability, and high strength. It is often used in applications that require moderate strength and resistance to atmospheric corrosion, such as building facades, signage, and automotive parts. 2. 5052 Alloy: This alloy is known for its high strength and excellent corrosion resistance. It is often used in marine and architectural applications where durability and resistance to saltwater and harsh environments are essential. It is also commonly used in the manufacturing of electrical enclosures and transportation equipment. 3. 6061 Alloy: This alloy is highly versatile and offers excellent weldability, formability, and machinability. It is often used in a wide range of applications, including aerospace components, marine hardware, structural components, and automotive parts. It has good corrosion resistance and can be easily powder-coated to enhance its appearance and provide additional protection. 4. 7075 Alloy: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used in aerospace applications, such as aircraft fittings and structural components, where strength and lightweight properties are crucial. Although it is less commonly used for powder-coated aluminum sheets due to its higher cost, it can still be found in certain specialized applications. These are just a few examples of the different types of alloys used for powder-coated aluminum sheets. The choice of alloy depends on the specific requirements of the application, including factors such as strength, corrosion resistance, formability, and cost.

Send your message to us

1/8 Aluminum Sheets - Mill Finish Aluminium Sheet AA1100 H14 for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords