Aluminum Color Sheets - AA1XXX Mill-Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

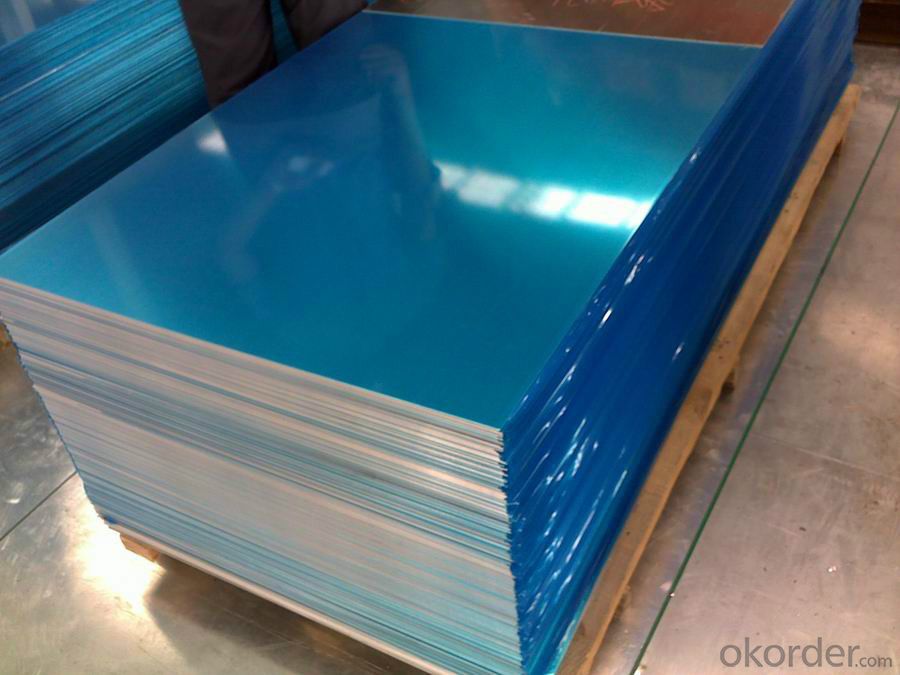

1.Structure of AA1xxx Mill-Finished Aluminum Sheets Used for Construction Description

AA1xxx Mill-Finished Aluminum Sheets Used for Construction is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1xxx Mill-Finished Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1xxx Mill-Finished Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

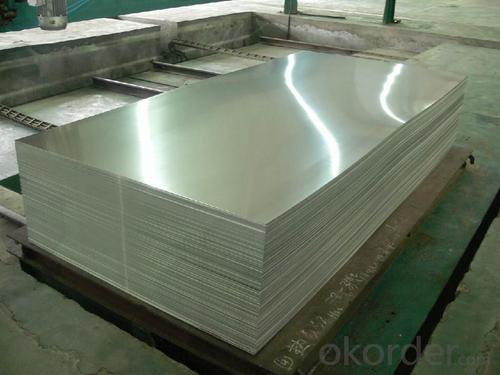

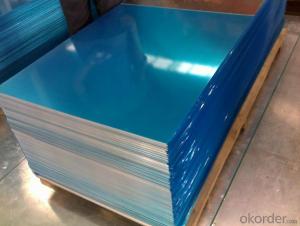

3.AA1xxx Mill-Finished Aluminum Sheets Used for Construction Images

4.AA1xxx Mill-Finished Aluminum Sheets Used for Construction Specification

Alloy | AA1xxx (AA1050, AA1060,AA1070, etc) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1xxx Mill-Finished Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA1xxx Mill-Finished Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What is aluminium oxide sheet?

- The oxidation of aluminum in natural and chemical oxidation, and oxidation of several, generally refers to the chemical oxidation oxidation plate plate, is the use of chemical reaction to aluminum formed on the surface of a white coating can reach the anticorrosion effect, can also be made, through technology, color, color, texture

- Q: Can the aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a preferred material for solar panel frames due to its lightweight, durable, and corrosion-resistant properties. It provides structural stability and ease of installation for the solar panels.

- Q: What kind of welding rod should be used for aluminum plate, welding and welding?.

- Ask for advice, the simplest and the most primitive way, sincerely ask for adviceChasing the answerThe welding method is the most original welding welding, but have difficulty, need certain skills. The simplest is not easy to say, if welding hand arc welding, in fact, the use of hand arc welding is relatively simple, and welding carbon steel is the difference between the welding speed, requiring faster response to the welder on the line. If there is no welding foundation, we can use TIG welding or MIG welding, both of which are simpler to learn, that is, the welding equipment that needs to be purchased is more expensive.

- Q: Is it suitable to use aluminum windows in areas with cold weather conditions?

- <p>Yes, you can use aluminum windows in cold climates, but there are considerations. Aluminum is a good conductor of heat, which can lead to heat loss in cold weather. To mitigate this, insulated glass units and thermally broken frames can be used. These designs slow down heat transfer, making aluminum windows more energy-efficient in cold climates. Additionally, proper sealing and weatherstripping are crucial to prevent drafts and ensure the windows perform well in low temperatures.</p>

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: Solid aluminum or solid wooden boxes-no glass top. Would glass make the temperature rise more quickly? (ie Solar)? Thanks.Joseph

- If all of the heat transfer is from the sun through the open top, a wooden box would keep the heat in, acting as an insulator. The aluminum box would quickly radiate away any trapped heat. If the heat is coming in through the walls, then aluminum would conduct the heat better. A glass top would definitely allow the sun's energy in while trapping the heat. That is how a greenhouse works! The aluminum vs. wood discussion still holds, wood is better in this situation.

- Q: Can aluminum sheets be used for roofing?

- Indeed, roofing can be done using aluminum sheets. The preference for aluminum in roofing material selection is attributed to its sturdy composition, low weight, and resistance to rusting. Aluminum roofing sheets have gained recognition for their impressive lifespan, capable of enduring for many years without requiring replacement. Furthermore, aluminum possesses exceptional reflective capabilities, aiding in reducing energy expenses by maintaining a cooler temperature within the structure in hot weather. Furthermore, aluminum is effortless to install, rendering it an appealing option for roofing ventures. In summary, aluminum sheets are a dependable and pragmatic alternative for roofing purposes.

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

- Q: Are aluminum sheets suitable for electronic enclosures?

- Yes, aluminum sheets are suitable for electronic enclosures. Aluminum is a lightweight and durable material that offers excellent conductivity and thermal management properties, making it ideal for electronic enclosures. It also provides good shielding against electromagnetic interference (EMI) and offers corrosion resistance, making it a popular choice in the electronics industry.

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- 7075 T6 hardness in 150HB, hardness is highestUsually 6061 and 6063 can be common

Send your message to us

Aluminum Color Sheets - AA1XXX Mill-Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords