Wholesale Aluminum Decorative Sheets for Wall Cladding, Facades, Roofing, Canopies, Tunnels, and Column Covers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

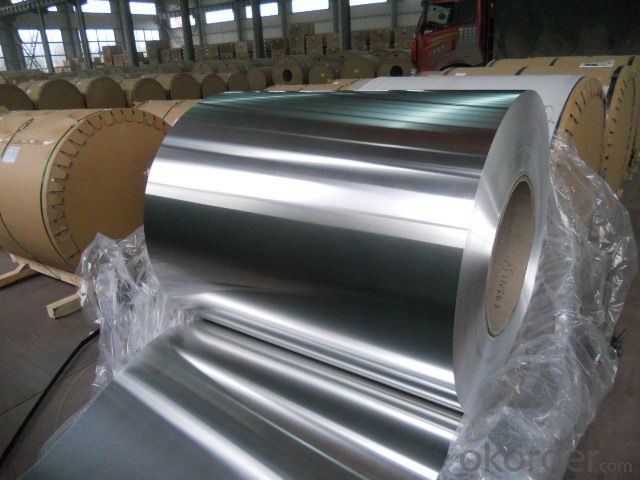

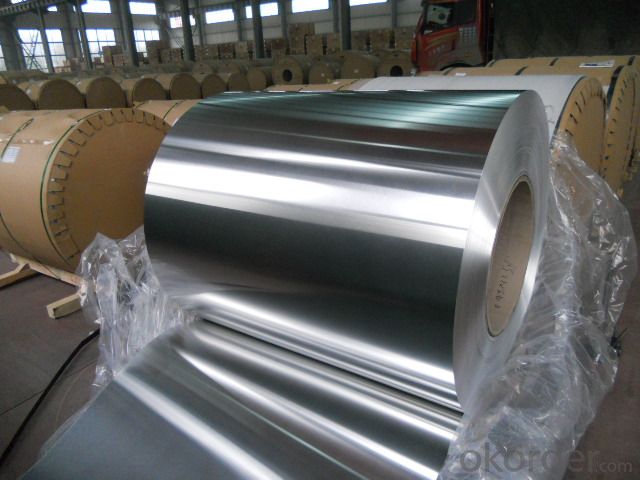

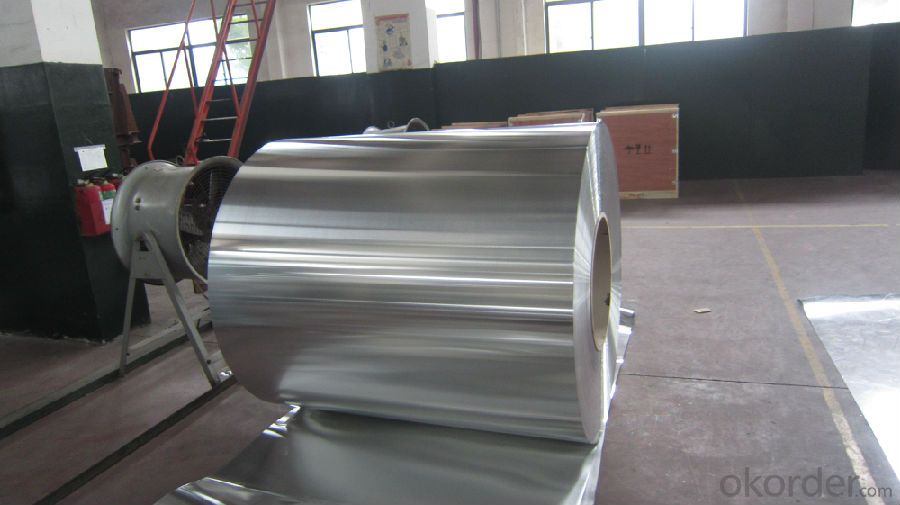

We are one of the largest aluminum producer in China, and we also use of aluminum rod, billets, rod, foils, sheet, circles, embossed coil etc.We have produced Aluminum Coils over 10 years, and we have good reputation of the price and quality in North part of China

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< p=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

.

- Q: What are the different surface finishes available for aluminum sheets?

- There are several different surface finishes available for aluminum sheets, each offering distinct characteristics and aesthetic appeal. Some of the commonly used surface finishes for aluminum sheets include: 1. Mill Finish: This is the most basic surface finish and is achieved by leaving the aluminum in its as-rolled condition, without any additional treatment. It has a smooth and shiny appearance, but may have minor imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and provides a wide range of color options. Anodized finishes can have a matte or glossy appearance. 3. Brushed Finish: This finish is achieved by brushing the aluminum sheet with a fine abrasive material, creating a textured pattern. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes and gives a high-end, mirror-like appearance to the aluminum. 5. Embossed Finish: Embossing is a process that creates raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, as it adds texture and visual interest to the material. 6. Powder Coated Finish: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This finish provides a durable and weather-resistant coating, and is available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting different patterns or designs on the surface of the aluminum sheet. This finish is often used for architectural applications and adds visual interest to the material. These are just a few examples of the different surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: whst should I notice while welding aluminum sheet and aluminum block?

- two types of aluminum reach melting points, aluminum block must be preheated when you weld them with small current, you will know how to do it. You can use argon-arc welding back and forth, preheat it with small current.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically classified as Class A, indicating a high level of fire resistance.

- Q: Is it possible to utilize a custom-made door in place of a standard door within a construction or renovation project?

- <p>Yes, you can use a custom-made door to replace a standard door in your project. However, it's important to ensure that the custom door meets all the necessary building codes and specifications required for your project. This includes considerations for size, material, fire resistance, insulation, and any other relevant standards. Additionally, you should consult with your architect or contractor to confirm that the custom door will fit properly within the existing framework and align with the overall design and functionality of the space.</p>

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum size of aluminum sheets can differ based on the manufacturer and specific use. Nonetheless, as a rule, aluminum sheets typically have a standard maximum size of 4 feet by 12 feet (48 inches by 144 inches). This size is widely employed across industries like construction, automotive, and aerospace. Nevertheless, it is crucial to acknowledge that certain suppliers may offer larger sizes upon request, albeit with additional expenses and factors to consider.

- Q: How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to know the dimensions (length, width, and thickness) of the sheet and the density of aluminum. The weight can be calculated by multiplying these three values together and then multiplying it by the density of aluminum.

- Q: What are the advantages of utilizing aluminum sheets in construction projects in terms of environmental impact?

- <p>Using aluminum sheets in construction offers several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing the carbon footprint associated with transportation. It also has a high strength-to-weight ratio, leading to less material usage and lower energy consumption in production. Additionally, aluminum's reflective properties can help in reducing heat absorption, contributing to energy efficiency in buildings. Moreover, aluminum production technology has advanced to minimize harmful emissions, making it a more sustainable choice for construction materials.</p>

- Q: Can aluminum sheets be used in automotive applications?

- Aluminum sheets find their utility in automotive applications. This lightweight and sturdy material brings a multitude of advantages to the manufacturing of automobiles. It is widely employed in the creation of car bodies, hoods, doors, roofs, and various other components. By incorporating aluminum sheets into automotive applications, the overall weight of the vehicle can be reduced, thereby enhancing both fuel efficiency and performance. Moreover, aluminum boasts exceptional resistance to corrosion, making it well-suited for enduring harsh weather conditions and exposure to road salt. Additionally, aluminum can be easily molded and shaped, facilitating intricate designs and detailing on automotive parts. In summary, the utilization of aluminum sheets in automotive applications contributes to the creation of vehicles that are lighter, more fuel-efficient, and visually appealing.

- Q: How do you calculate the price and weight of aluminum sheet?

- Our company imports more materials. It will be much more expensive if you are short of itAluminum prices have gone up this year

- Q: Does it make any difference shiny side up, shiny side down when it comes to cooking with aluminum foil?

- The dull/shiny question was on the top of their list! Aren't you glad this answer is out in the open now?!

Send your message to us

Wholesale Aluminum Decorative Sheets for Wall Cladding, Facades, Roofing, Canopies, Tunnels, and Column Covers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords