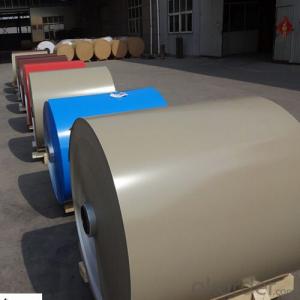

Large 5086 Aluminum Sheets and 6061 Aluminum Coils for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of 6061 Aluminium Coils

|

Alloy |

AA6061 |

|

Temper: |

T, H112, H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

|

Thickness: |

0.10-500mm |

|

Width: |

10mm- 2200mm |

|

Standard: |

GB/T3880-2006, ASTM, ISO, EU standard |

|

Special Specification is available on customer’s requirement | |

2. Applications of 6061 Aluminium Coils

6061 Aluminium Coils have high / medium strength, good mechanical properties and good corrosion resistance. The alloy can be well anodized, so it is applied to various structural component requiring medium strength, high weldability and corrosion resistance, such as plate, tube, bar and section material used in truck, tower building, vessel, trolley, railway vehicle and furniture.

3. Package & Delivery of 6061 Aluminium Coils

Seaworthy package, water-proof paper wrapped inside, carton wrapped outside in wooden pallets by 20FCL or 40GP.

4. Production Flow of 6061 Aluminium Coils

The main producingprocedure of 6061 Aluminium Coils includes the following steps:

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: If not, where can i buy some aluminum?

- is your minuscule excuse for a dick a dick?

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are highly suitable for signage applications due to their durability, lightweight nature, and ability to withstand various weather conditions. They are also easy to customize, making them a popular choice for both indoor and outdoor signage.

- Q: What kind of material is 2A12 aluminum sheet?

- 2A12 is a typical Al Mg alloy in Al Cu mg system. Its composition is reasonable and its comprehensive properties are better. Many countries produce this alloy, which is the largest in use. The alloy is characterized by high strength, a certain heat resistance, and can be used as working parts below 150 degrees C.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: How does aluminum sheet compare to other metals in terms of weight?

- Aluminum sheet is exceptionally lightweight compared to most other metals. It has a lower density, making it a popular choice for applications where weight reduction is a priority.

- Q: im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. The surface of the aluminum sheet can be prepared by cleaning and etching to ensure proper adhesion of the paint or coating.

- Q: How does the purity of aluminum affect its properties as a sheet?

- The properties of aluminum as a sheet are significantly influenced by its purity. Increased levels of purity generally lead to improved mechanical properties, as well as enhanced thermal and electrical conductivity, and better resistance against corrosion. When aluminum possesses a high level of purity, meaning it contains minimal impurities, it becomes more malleable and ductile. This characteristic makes it easier to shape into thin sheets, rendering highly pure aluminum sheets more appropriate for applications requiring intricate shapes and designs. Moreover, the high electrical conductivity of pure aluminum makes it an exceptional choice for electrical applications, such as wiring and circuit boards. It enables efficient transmission of electricity while minimizing the risk of overheating. Additionally, the thermal conductivity of pure aluminum makes it an ideal option for heat transfer purposes. Aluminum sheets with a high level of purity can effectively dissipate heat, making them well-suited for applications like heat sinks and radiators. Furthermore, the corrosion resistance of aluminum increases with higher levels of purity. Pure aluminum forms a protective oxide layer on its surface, which serves to prevent corrosion and prolong the lifespan of aluminum sheets in various environments. In conclusion, the purity of aluminum directly impacts its properties as a sheet. Increased levels of purity enhance its mechanical properties, as well as its electrical and thermal conductivity. Additionally, it improves its resistance against corrosion, making it more versatile and suitable for a wide range of applications.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

- Q: What is the typical fatigue life of aluminum sheets?

- The typical fatigue life of aluminum sheets can vary depending on several factors such as the alloy used, sheet thickness, manufacturing process, and the specific application it is being used for. Generally, aluminum sheets have a relatively high fatigue strength compared to other materials, allowing them to withstand a large number of cyclic loading cycles before failure. However, it is important to note that fatigue life can be influenced by various factors such as stress levels, loading conditions, and environmental factors like temperature and humidity. Aluminum sheets may experience a decrease in fatigue life when subjected to high stress levels, cyclic loading, or harsh environmental conditions. In certain applications where aluminum sheets are subjected to low stress levels or are not exposed to cyclic loading, they can have an infinite fatigue life. On the other hand, in high-stress applications or when subjected to cyclic loading, aluminum sheets typically have a finite fatigue life that can range from thousands to millions of cycles. To determine the precise fatigue life of aluminum sheets for a specific application, it is recommended to refer to relevant industry standards, test data, or consult with material engineers or manufacturers who can provide more accurate information based on the specific parameters and conditions of use.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Large 5086 Aluminum Sheets and 6061 Aluminum Coils for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords