Oem Aluminum Veneer Sheets - 5052 Aluminium Checker Plate for Boat Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

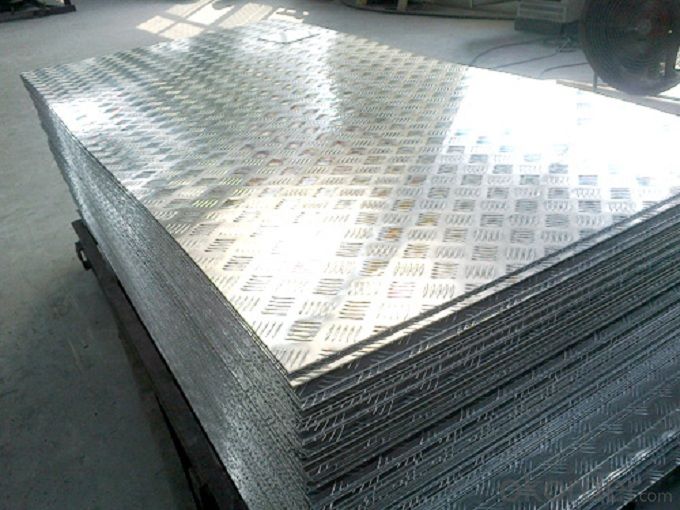

5052 Aluminium Checker Plate for Boat Deck

l Description

1.Alloy number: 1100,3003,1050,1060,5052.

2.Temper: H14,H18,H12,H16,H22,H26,H24.

3.Brand: CMAX

4.Thickness: 0.8-10.0mm. width: 20-1600mm.

5.Tolerance: thick+/-0.02mm, width +/-0.5mm.

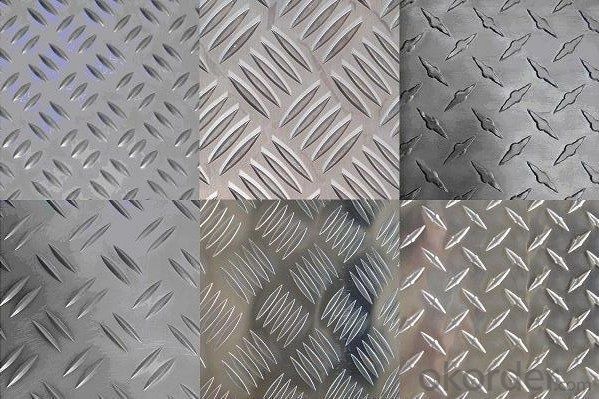

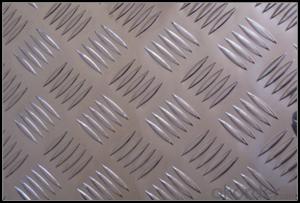

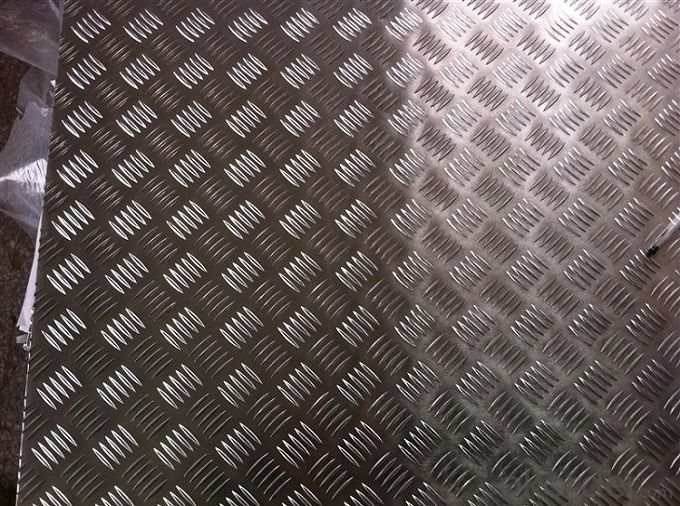

6.Pattern: Two bars, Three bars, Five bars and Diamond.

7.Surface brightness: bright surface or normall surface.

8.Application: trailer,truck,decking,flooring,stairs,steps,building industry.

9.Loading port: Shanghai or main port in China.

l Packaging & Delivery

Packaging detail: wooden pallets that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. Aluminium checker plate is a popular product in CNBM. With best quality and service, we have won reputation around the world.. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: How does the surface roughness affect the friction properties of aluminum sheet?

- The surface roughness of an aluminum sheet affects its friction properties by increasing the surface area in contact with another object, leading to higher frictional forces. A rougher surface will have more irregularities and asperities, creating more points of contact and interlocking with the opposing surface. This increased contact area enhances the adhesion between the surfaces, resulting in higher friction. Conversely, a smoother surface with fewer irregularities will have reduced contact area and less adhesion, leading to lower friction.

- Q: Can aluminum sheet be used for heat exchangers?

- Indeed, aluminum sheet can be effectively utilized in heat exchangers. The utilization of aluminum as a material for heat exchangers is widespread owing to its remarkable thermal conductivity, lightweight nature, and resistance to corrosion. The remarkable thermal conductivity of aluminum facilitates the efficient transfer of heat between fluids, rendering it suitable for a multitude of heat exchange applications. Furthermore, aluminum is obtainable in diverse alloys and thicknesses, granting adaptability in design and customization to cater to specific heat exchanger prerequisites. On the whole, aluminum sheet emerges as a favored option for heat exchangers in industries encompassing automotive, HVAC, and aerospace.

- Q: Maybe you didn't know but in the year 2025 the earth's population will be up to 12 billion people, which is double what we have now. And i am doing a project on Aluminum, and I have to know if there is enough AL for this many people in the year 2025. So will there be enough AL in the world to support us all?

- Aluminium is the third most abundant element on earth after oxygen and silicon. I am quite sure that we will not run out of aluminium in the future. Oxygen - or at least pure good quality oxygen - is probably a more worrying scenario.

- Q: Some say you should use the 'dull' side of aluminum foil when cooking etc. There's something potentially bad about the shiny side.True or not?

- For a pocket stew the dull side is on the outside to absorb the heat and the shiny side is on the inside to keep reflecting the heat into the stew. For a kite flying at night that might be reported as a UFO I would recommend shiny side at the front.

- Q: What is the typical sheet size tolerance for aluminum sheets?

- The typical sheet size tolerance for aluminum sheets is typically around +/- 0.005 to 0.010 inches.

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess several physical properties, including being lightweight, corrosion-resistant, and having a high strength-to-weight ratio. They are also ductile, meaning they can be easily shaped or formed without breaking. Additionally, aluminum sheets have excellent thermal and electrical conductivity, making them suitable for various applications in industries such as construction, aerospace, and automotive.

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: How do I join aluminum sheets together?

- One common method to join aluminum sheets together is through welding. Aluminum can be welded using various techniques such as Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding. These methods involve melting the edges of the aluminum sheets and fusing them together using a filler material. Another option is using adhesives specifically designed for aluminum bonding. These adhesives create a strong bond between the sheets when applied correctly. Additionally, mechanical fastening methods like riveting or bolting can also be used to join aluminum sheets together. The appropriate method depends on factors such as the specific application, desired strength, and aesthetic requirements.

- Q: What is aluminum sheet?

- Aluminum sheet refers to a flat, thin piece of aluminum that is commonly used in various industries and applications. It is produced by rolling aluminum ingots between large rollers to achieve the desired thickness. Aluminum sheets are lightweight, durable, and have excellent corrosion resistance, making them suitable for a wide range of uses. They are commonly used in the construction industry for roofing, siding, and insulation purposes. Additionally, aluminum sheets are widely used in the automotive, aerospace, packaging, and electrical industries due to their high conductivity and ability to be easily molded into different shapes. Overall, aluminum sheets are versatile and highly sought after for their strength, flexibility, and aesthetic appeal.

Send your message to us

Oem Aluminum Veneer Sheets - 5052 Aluminium Checker Plate for Boat Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords