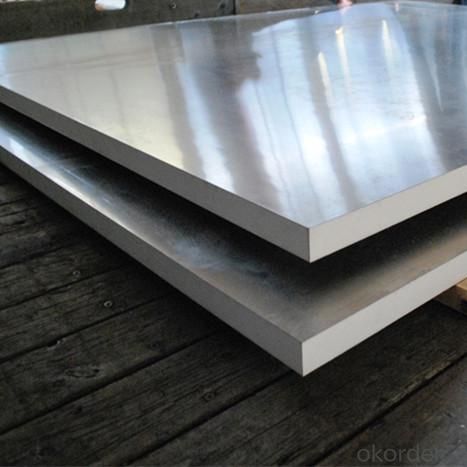

Thin Sheets of Aluminum 5052 - Thickness 0.1mm to 500mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Plates 5052

Alloy Number | AA1050 , AA1060 ,AA1070 ,AA1100 etc. |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Plates 5052

Aluminum Plates is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum plates which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3 Packaging & Delivery of Aluminum Plates 5052

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Aluminum Plates 5052

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

5052-H32 Aluminum Plate - (ASTM B209, QQ-A-250/8) Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Plate a common choice for chemical, marine or saltwater applications. 5052 Aluminum Plate applications include: tanks, drums, marine hardware, boat hulls, etc.

Non-magnetic, Brinell = 60, Tensile = 33,000, Yield = 28,000 (+/-)

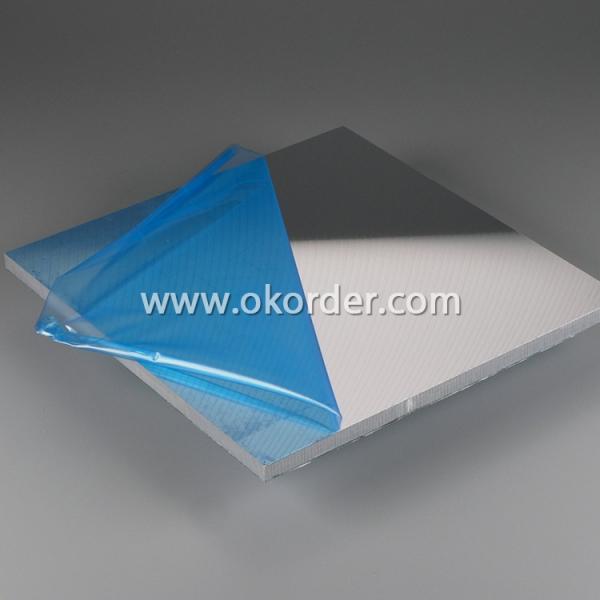

- Q: Can aluminum sheets be coated with protective films?

- Yes, aluminum sheets can be coated with protective films. These films are typically made of materials such as polyethylene or polypropylene and are designed to provide a barrier against scratches, abrasions, and other forms of damage. The protective film is applied to the surface of the aluminum sheet, creating a layer that shields it from potential harm during handling, transportation, or processing. This coating process helps to maintain the integrity and appearance of the aluminum sheet, ensuring that it remains in excellent condition until it is ready for use.

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Aluminum cans melt at about 1220 F. Lava is about 1300F to 2400F. The can would melt into the lava.

- Q: Can the aluminum sheets be used for manufacturing electronic heat sinks?

- Yes, aluminum sheets can be used for manufacturing electronic heat sinks. Aluminum is a popular choice for heat sink material due to its excellent thermal conductivity and lightweight properties. It efficiently transfers heat away from electronic components, helping to dissipate and manage heat generated during operation. Aluminum sheets can be easily formed and shaped into the desired heat sink design, providing effective cooling for electronic devices.

- Q: Consider an aluminum wire of diameter 0.580 mm and length 28.0 m. The resistivity of aluminum at 20.0°C is 2.82 10-8 Ω · m.(a) Find the resistance of this wire at 20.0°C. ___________Ω(b) If a 9.00-V battery is connected across the ends of the wire, find the current in the wire. __________A

- Resistivity Of Aluminum Wire

- Q: Are there any specific storage requirements for 101 aluminum sheets?

- Yes, there are specific storage requirements for 101 aluminum sheets. Aluminum sheets should be stored in a clean and dry area to prevent any moisture absorption or corrosion. They should be kept in a well-ventilated space to avoid the buildup of any potentially harmful gases. It is important to stack the sheets properly, with adequate support and spacing, to prevent any bending or deformation. Additionally, aluminum sheets should be protected from direct sunlight to avoid any discoloration or fading. It is recommended to cover them with a suitable material, such as a plastic sheet or tarp, to provide an extra layer of protection. Proper storage conditions will help maintain the quality and integrity of the aluminum sheets for their intended use.

- Q: Can the aluminum sheets be used for manufacturing chemical piping systems?

- Indeed, the utilization of aluminum sheets in the production of chemical piping systems is plausible. Renowned for its remarkable resistance against corrosion, aluminum proves to be apt for handling an array of chemicals. Moreover, its lightweight nature facilitates effortless installation and maintenance procedures. Furthermore, aluminum possesses commendable thermal conductivity, thereby enabling efficient heat transfer within chemical processes. Nonetheless, it is crucial to contemplate the distinctive demands imposed by the chemicals being conveyed and seek guidance from specialists to guarantee the selection of aluminum sheets equipped with indispensable properties and compatibility with the chemicals to be employed within the piping system.

- Q: why can aluminum sheet after oxide film removal react quicker with hydrochloric acid?

- the reason is very simple, the original aluminum sheet has a layer of dense oxide film AI2O3, which has prevented the inner aluminum sheet from reacting with hydrochloric acid. but after oxide film removal, aluminum sheet will directly contact hydrochloric acid, generating H2.

- Q: How do aluminum sheets compare to other metals in terms of strength?

- Compared to other metals, aluminum sheets typically possess lower strength. Although aluminum is lightweight and exhibits excellent corrosion resistance, it lacks the same level of strength as steel or titanium. In terms of tensile strength and yield strength, aluminum falls short when compared to these metals, rendering it more susceptible to deformation and failure when subjected to heavy loads. Nevertheless, by alloying aluminum with other elements, its strength can be enhanced, allowing certain aluminum alloys to compete with or even surpass the strength of certain other metals. Furthermore, aluminum's strength-to-weight ratio stands as one of its primary advantages, making it the preferred choice in industries where weight reduction is critical, such as aerospace and automotive. All in all, while aluminum may not possess the highest level of strength among metals, its combination of strength, lightweight properties, and corrosion resistance renders it an adaptable material for various applications.

- Q: Are aluminum sheets suitable for automotive body reinforcements?

- Aluminum sheets, indeed, prove to be a fitting option for reinforcing automotive bodies. With its lightweight properties and exceptional strength-to-weight ratio, aluminum emerges as the perfect candidate for various automotive applications. Furthermore, its resistance to corrosion becomes vital for vehicles navigating through diverse weather conditions and encountering road salts. Moreover, the malleability and weldability of aluminum sheets make them easily adaptable and seamlessly integrated into the body structure. By incorporating aluminum sheets in automotive body reinforcements, the overall weight of the vehicle diminishes, leading to enhanced fuel efficiency and performance. Additionally, the recyclable nature of aluminum aligns perfectly with the automotive industry's growing emphasis on sustainability. Therefore, unquestionably, aluminum sheets represent an ideal choice for reinforcing automotive bodies.

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Thin Sheets of Aluminum 5052 - Thickness 0.1mm to 500mm

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords