1/16 Aluminum Plate

1/16 Aluminum Plate Related Searches

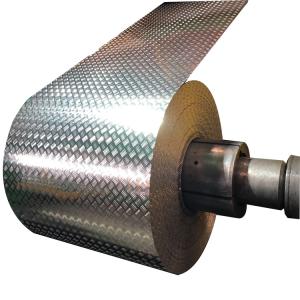

1/16 Diamond Plate Aluminum 1 16 Aluminum Plate 3/16 Aluminum Plate 5/16 Aluminum Plate 3/16 Inch Aluminum Plate 7/16 Aluminum Plate 3/16 Thick Aluminum Plate Aluminum 3/16 Plate Aluminum Plate 3/16 Thick 1/4 Aluminum Plate 1/8 Aluminum Plate Aluminum Plate 1/4 1/2 Aluminum Plate Aluminum 1/2 Plate Aluminum 1/4 Plate 1/4 Plate Aluminum 1 Inch Aluminum Plate 1/4 Inch Aluminum Plate 1/4in Aluminum Plate 1/4 Thick Aluminum Plate 1/8 Inch Aluminum Plate 3/16 Diamond Plate Aluminum 1/2 Inch Aluminum Plate 1 Aluminum Plate 1/8 In Aluminum Plate 3/16 Aluminum Diamond Plate Aluminum Plate 1/4 Thick Bending 3/16 Aluminum Plate 1 16 Aluminum Diamond Plate 1/4 Inch Thick Aluminum Plate1/16 Aluminum Plate Supplier & Manufacturer from China

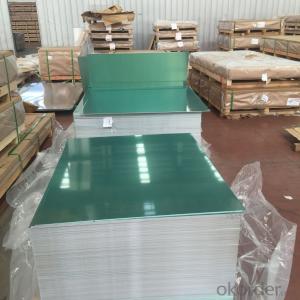

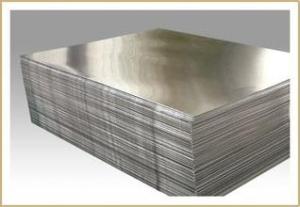

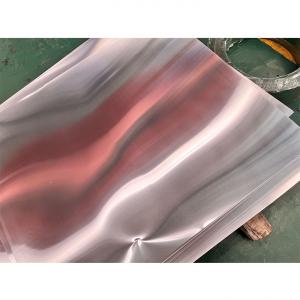

1/16 Aluminum Plate, a versatile and lightweight material, is widely recognized for its durability and corrosion resistance. This product is commonly used in various industries such as construction, automotive, aerospace, and more, due to its high strength-to-weight ratio and ease of fabrication. It is particularly suitable for applications where weight reduction and material strength are critical factors.The 1/16 Aluminum Plate is utilized in numerous scenarios, including but not limited to, structural components, decorative panels, and heat sinks. Its malleability and formability make it an ideal choice for intricate designs and complex shapes, which are often required in modern engineering and architectural projects. The material's non-magnetic properties also make it a preferred option for applications where electromagnetic interference is a concern.

Okorder.com is a reputable wholesale supplier of 1/16 Aluminum Plate, boasting a vast inventory to cater to the diverse needs of clients across different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 1/16 Aluminum Plate is sourced from reliable manufacturers and is available at competitive prices, making it an attractive option for businesses looking to optimize their material costs without compromising on performance.

Hot Products