Mill Finish Aluminum Sheets AA1100 H14 for Curtain Wall and Building Boats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

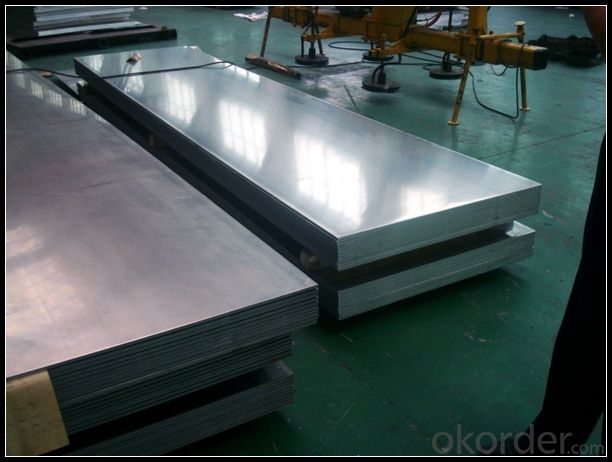

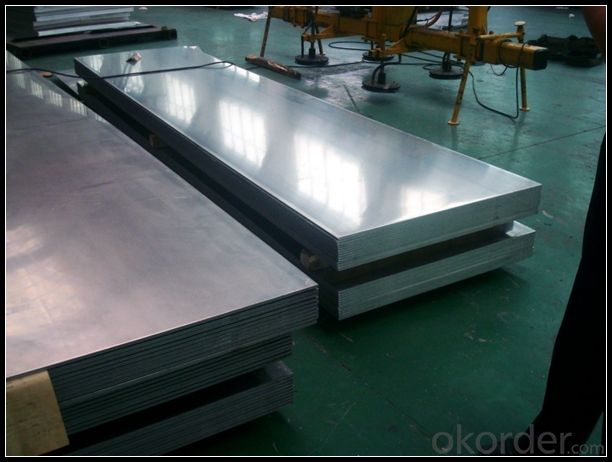

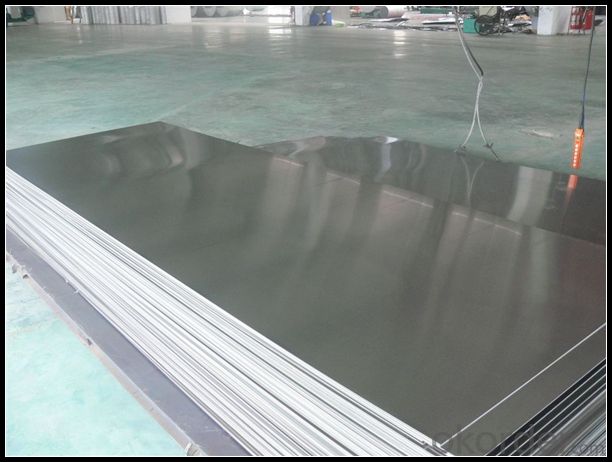

5. Image of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

6. Package and shipping of Mill Finish Aluminium Sheet AA1100 H14 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for air conditioning systems?

- Indeed, air conditioning systems can make use of aluminum sheets. Due to its remarkable heat transfer properties, aluminum is widely employed in the fabrication of air conditioning systems. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity render it a perfect material for producing coils, fins, and heat exchangers within air conditioning units. Furthermore, aluminum sheets can be effortlessly manipulated and molded into diverse forms and dimensions, thereby enabling flexibility in both design and installation.

- Q: What is the coefficient of friction for aluminum sheets?

- The coefficient of friction for aluminum sheets can vary depending on the specific conditions, such as the surface it is in contact with and the presence of lubricants or contaminants. In general, the coefficient of friction for aluminum sheets is relatively low, ranging from 0.2 to 0.6. However, it is important to note that these values are approximate and can be influenced by various factors.

- Q: What are the common sizes of aluminum sheet?

- Some common sizes of aluminum sheet include 4x8 feet (48x96 inches), 4x10 feet (48x120 inches), and 5x10 feet (60x120 inches).

- Q: Can aluminum sheets be used for HVAC systems?

- Certainly, HVAC systems can utilize aluminum sheets. Aluminum proves to be a favored material for HVAC applications owing to its numerous beneficial characteristics. Its lightweight nature facilitates effortless handling and installation. Moreover, aluminum exhibits remarkable resistance to corrosion, a vital attribute for HVAC systems subject to moisture and fluctuating temperatures. Additionally, aluminum boasts exceptional thermal conductivity, ensuring efficient heat transfer. Consequently, it becomes ideal for heat exchangers and other HVAC system components. In summary, aluminum sheets emerge as a dependable and long-lasting choice for HVAC systems.

- Q: Are the aluminum sheets suitable for manufacturing electrical busbars?

- Yes, aluminum sheets are suitable for manufacturing electrical busbars. Aluminum is a popular choice for busbars due to its excellent electrical conductivity and lightweight properties. It can efficiently conduct high electrical currents and has low resistance, making it ideal for conducting electricity in power distribution systems. Additionally, aluminum sheets can be easily fabricated and formed into various shapes and sizes, allowing for customization and efficient installation in electrical systems.

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Now, there are many kinds of ceramic curtain walls. They are made of natural clay materials. They are green, environmentally friendly, low energy consumption, and they are not easy to fade and deform. They have good corrosion resistance and durability, and high strength. At present, the domestic market of ceramic tile is faster than that of foreign countries. I heard ruigao is the first manufacturer of ceramic plate, there are other TOB ah, new Kerry ah. The strength is good.

- Q: What kind of aluminum sheet can be bent with five millimeters?

- The aluminum plate can be bent five milimeter too much, if only bending words and aluminum quality has little relationship.First of all, the state is the most important, the state is divided into hard, semi hard, soft (usually soft called O state)The bending effect of the whole hard is not too far (the aluminum plate is H18, H19, H38 and so on are all hard)Semi hard aluminum sheets can basically be bent (H24, that is, semi hard)O bending is certainly not a problem, but because of too soft, basically with this state to bend lessSecond, you have to choose pure aluminum or alloy aluminum?Pure aluminum hardness is not very good, with 1100, 1050, 1060 and so on can be recommended 1100 H26Alloy aluminum hardness is better, can use 3003, 3005, 5052 and other semi hard state can be.Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.If the aluminum surface paint it quality do not too good, good is a waste, it is recommended to use 3003-H26, 3005H24 or 5052H34, the price of twenty pieces of it, made up to more than forty yuan per kilogram

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q: How do aluminum sheets perform in terms of thermal expansion and contraction?

- Aluminum sheets have a relatively high coefficient of thermal expansion, meaning they expand and contract more than most other materials when exposed to heat or cold. The coefficient of thermal expansion for aluminum is approximately 23 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, aluminum will expand by 23 millionths of its size. This thermal expansion and contraction property of aluminum makes it suitable for various applications where temperature fluctuations are expected. For instance, in the construction industry, aluminum sheets are commonly used for roofing and cladding purposes. These sheets can withstand the thermal stresses caused by the changing temperatures without warping or distorting significantly. Moreover, this characteristic of aluminum also makes it ideal for manufacturing products like cookware and heat sinks. Aluminum cookware heats up quickly and evenly due to its high thermal conductivity and expands uniformly, preventing warping or deformation when exposed to heat. Similarly, aluminum heat sinks effectively dissipate heat generated by electronic components, as they can accommodate thermal expansion without compromising their structural integrity. However, it is important to note that while aluminum sheets have good thermal expansion and contraction properties, extreme temperature changes can still lead to some dimensional changes. Therefore, proper consideration of the anticipated temperature variations is crucial when designing and using aluminum sheets to ensure their optimal performance and longevity.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be bent or formed into different shapes through processes such as bending, rolling, or pressing, due to its malleability and ductility.

Send your message to us

Mill Finish Aluminum Sheets AA1100 H14 for Curtain Wall and Building Boats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords