Aluminum Camper Siding 12 Sheets - Aluminium Checkered Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

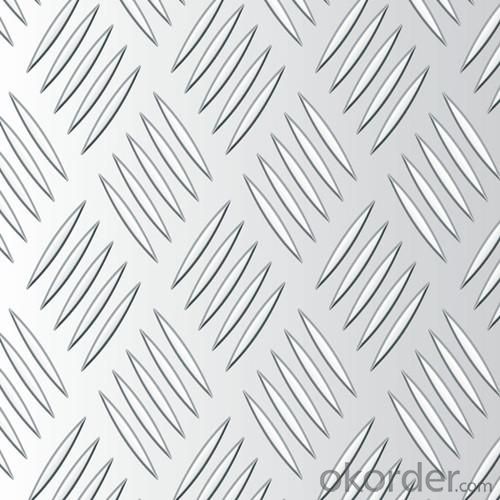

1. Specifications of Aluminum Checkered Sheet

| MAIN SPECIFICATION OF ALUMINUM CHECKERED SHEET | |

| Alloy | AA1XXX (AA1050, AA1060, AA1070, AA1100 etc.) |

| AA3XXX (AA3003, AA3004, AA3005, AA3105 etc.) | |

| AA5XXX(AA5052) | |

| Temper | H14,H18,H24, H26, H32 |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

| Special specification is available on customer's requirement | |

2. Usage/Applications of Aluminum Checkered Sheet

The embossed aluminum sheet are widely used for decorative purposes in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packing & Delivery of Aluminum Checkered Sheet

Packaging: Seaworth package

Shipment: The goods will be delivered in not more than 40 days after getting the buyer's payment.

4. Process Flow of Aluminum Checkered Sheet

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: Describe the steps involved in installing aluminum sheets on a roof.

- <p>Installing aluminum sheets on a roof involves several key steps: 1) Inspect the roof structure to ensure it can support the new material. 2) Remove any existing roofing material. 3) Install roof underlayment to protect against moisture. 4) Position the first aluminum sheet at the lowest point of the roof, aligning it with the eaves. 5) Secure the sheet using clips or screws, ensuring a watertight seal. 6) Continue installing sheets up the roof, overlapping each by at least 2 inches for a secure fit. 7) Cut and fit sheets around vents, pipes, and other roof protrusions. 8) Install flashing and trim to finish edges and seal the roof. 9) Check for proper alignment and secure all fasteners. 10) Clean up debris and inspect the installation for any gaps or leaks.</p>

- Q: How do you ensure the surface quality of aluminum sheets?

- To guarantee the surface quality of aluminum sheets, manufacturers can take several steps: 1. Cleanliness is crucial. Prior to any surface treatment or inspection, it is vital to thoroughly clean the aluminum sheets and eliminate any dirt, grease, or contaminants. This can be accomplished using solvents, detergents, or specialized cleaning agents. 2. A visual inspection is necessary. Trained personnel should visually inspect the surface for visible flaws such as scratches, dents, or pitting. Proper lighting and magnification tools should be utilized. 3. Chemical treatments may be required. Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments such as anodizing, chromate conversion coating, or passivation. These processes can enhance the sheets' surface quality, corrosion resistance, and aesthetic appearance. 4. Mechanical polishing can be employed. To eliminate surface imperfections and achieve a smooth, glossy finish, mechanical polishing techniques like grinding, buffing, or sanding can be utilized. It is important to maintain consistency and avoid over-polishing, which can compromise the integrity of the sheets. 5. Coating and protection are essential. Applying protective coatings like lacquers, paints, or powder coatings can further improve the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality control is crucial. Rigorous quality control procedures should be implemented throughout the manufacturing process. Regular inspections, testing, and documentation should be conducted to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Proper handling and packaging are necessary. To prevent surface damage during transportation and storage, it is important to handle and package the sheets correctly. Protective measures such as using protective films, paper interleaves, or cushioning materials should be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure that the surface quality of aluminum sheets meets the desired specifications and exceeds customer expectations.

- Q: What is the weight of a standard aluminum sheet?

- Depending on its dimensions and thickness, the weight of a standard aluminum sheet may vary. On average, aluminum sheets tend to weigh approximately 2.7 grams per cubic centimeter. If you wish to ascertain the weight of a particular aluminum sheet, you must possess knowledge of its dimensions (length, width, and thickness). By multiplying these dimensions, you can determine the sheet's volume. Subsequently, you can calculate the weight in grams by multiplying the volume by the density of aluminum (2.7 g/cm³).

- Q: Is it possible to use aluminum sheets as a material for interior walls?

- <p>Yes, aluminum sheets can be used for interior walls. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum sheets can also be painted or finished in various ways to match different interior design styles. They are lightweight, which makes them easy to install, and they provide good thermal insulation. However, it's important to consider the acoustic properties and the need for proper insulation to prevent condensation, especially in colder climates.</p>

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Microstructure characteristics of hot dipped aluminized steelHot dip aluminizing steel to achieve the combination of atoms between iron and aluminum by metal bond, close together, as was shown under the microscope, from the outside to the inside with two aluminum film, three aluminum oxide layer, the alloy layer sequentially formed coating. If the coating of carbon steel, the banded structure and base metal contact.Coating thickness: if carbon steel, then the aluminum layer is 0.04-0.07mm alloy layer, the average 0.05mm. However, the thickness of each layer depends on the type of steel, the amount of carbon, and the temperature and time of the dipping. If the parent material is alloy steel, coating and the differences (omitted).

- Q: How do aluminum sheets compare to other metals in terms of strength?

- Compared to other metals, aluminum sheets typically possess lower strength. Although aluminum is lightweight and exhibits excellent corrosion resistance, it lacks the same level of strength as steel or titanium. In terms of tensile strength and yield strength, aluminum falls short when compared to these metals, rendering it more susceptible to deformation and failure when subjected to heavy loads. Nevertheless, by alloying aluminum with other elements, its strength can be enhanced, allowing certain aluminum alloys to compete with or even surpass the strength of certain other metals. Furthermore, aluminum's strength-to-weight ratio stands as one of its primary advantages, making it the preferred choice in industries where weight reduction is critical, such as aerospace and automotive. All in all, while aluminum may not possess the highest level of strength among metals, its combination of strength, lightweight properties, and corrosion resistance renders it an adaptable material for various applications.

- Q: There seems to be a load of buzz out there regarding the use of aluminum pots and pans. They apparently may cause Alzheimer’s or bone degeneration in women. I have some cast iron pans that I use when ever possible but they are not always practical. I’d like some of you kitchen pros to give me some sound advice regard the use of aluminum in the home kitchen. I know they are used in food service organizations.... I look forward to some informative replys.Thanks in advance.

- each thing you do in any given day would reason some style of maximum cancers. you may could be residing in a bubble to not be uncovered. of direction, the bubble could be produced from some style of plastic which of direction would desire to divulge you to 3 strand of maximum cancers besides.

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Indeed, aircraft manufacturing finds aluminum sheets to be highly suitable. The aerospace industry extensively utilizes aluminum owing to its exceptional blend of qualities, encompassing its lightweight nature, robust strength, ability to withstand corrosion, and outstanding malleability. Such attributes render aluminum an optimal substance for constructing diverse aircraft elements, including fuselages, wings, and structural components. Furthermore, aluminum alloys can be effortlessly fused, facilitating efficient manufacturing procedures. In totality, aluminum sheets assume a pivotal function in aircraft manufacturing, substantially enhancing the aircraft's overall performance, durability, and safety.

- Q: Can aluminum sheets be anodized with custom colors?

- Custom colors can indeed be applied to aluminum sheets through the process of anodizing. Anodizing involves the application of an electrochemical procedure that adds a protective oxide layer to the aluminum's surface, thereby enhancing its durability and resistance to corrosion. In this process, the aluminum sheet is submerged in an electrolytic solution while an electrical current is passed through it. This induces a controlled oxidation of the aluminum's surface, leading to the formation of a porous layer that can be colored with dyes to achieve desired shades and hues. By carefully selecting the appropriate dye, a wide array of custom color options can be achieved. Moreover, anodized aluminum sheets offer versatility as they can undergo additional treatments like laser engraving or printing to create distinctive designs and patterns. Therefore, they are highly suitable for a diverse range of applications in industries such as architecture, automotive, and electronics.

- Q: How do aluminum sheets perform in terms of machinability?

- Aluminum sheets are known for their excellent machinability. They can be easily cut, drilled, and shaped using various machining processes. The softness and low melting point of aluminum make it highly conducive to machining operations. Additionally, aluminum sheets exhibit good chip formation and evacuation, resulting in smooth and efficient machining.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Camper Siding 12 Sheets - Aluminium Checkered Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords