Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

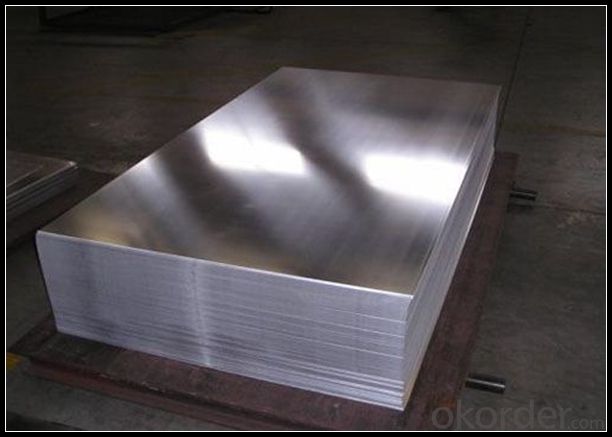

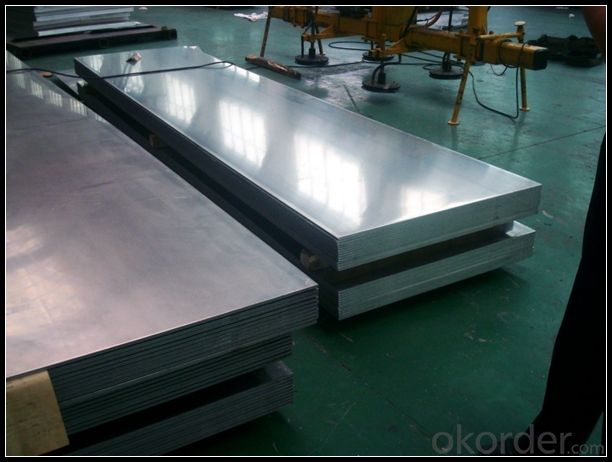

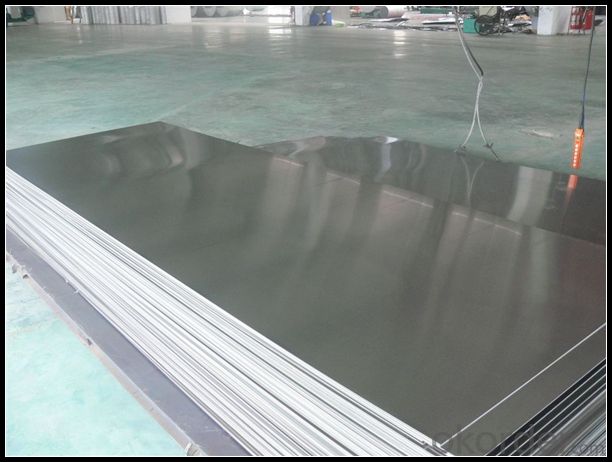

5. Image of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

6. Package and shipping of Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Q. Calculate the number of aluminium ions present in 0.051 g of aluminium oxide.( Hint: The mass of an ion is the same as that of an atom of the same element. Atomic mass of Al = 27 u) Please Explain each and every step!!!Thankx..A lot !!

- The formula for aluminium oxide is Al2O3 Its molecular weight is 2*27+3*16= 54+48 =102 Now, 102g of Al2O3 contains 2*6.023*10^23 number of Al ions so 1g contains (2*6.023*10^23)/102 number of Al ions so 0.051g Al2O3 contain (2*6.023*10^23)/102 *0.051 number of Al ions which is equal to 6.023*10^23*10^-3 = 6.023*10^20 number of Al ions(Answer)

- Q: What specific conditions or regulations must be met when using aluminum sheets in commercial construction?

- <p>Yes, there are special requirements for using aluminum sheets in commercial buildings. These include adherence to building codes and standards for fire resistance, structural integrity, and weather resistance. Aluminum sheets must meet specific thickness and strength requirements depending on the application. They also need to comply with environmental regulations regarding sustainability and recyclability. Additionally, for aesthetic purposes, the finish and color of the aluminum sheets should be in line with architectural design guidelines. It's crucial to consult with architects, engineers, and local building authorities to ensure all requirements are met.</p>

- Q: Could you tell me the difference between the 6063 aluminum plate and the 5052 aluminum plate?

- The difference is that, in addition to the magnesium Mg element, there is also a silicon Si element in the 6063 aluminum plate. The strength is slightly better than that of 5052

- Q: Are aluminum sheets resistant to vibration?

- Aluminum sheets, in general, demonstrate resistance towards vibration. Being a lightweight and flexible material, aluminum possesses excellent damping characteristics, enabling it to effectively absorb and dissipate vibrations. Moreover, aluminum exhibits a high strength-to-weight ratio, ensuring its structural integrity remains intact under vibrating conditions. Consequently, aluminum sheets are highly favored in sectors like aerospace, automotive, and construction, where protection against vibrations is crucial. Nevertheless, it is important to acknowledge that the degree of vibration resistance may differ depending on various factors such as the thickness and alloy composition of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a durable, corrosion-resistant layer on the surface of aluminum. This process can be applied to aluminum sheets to enhance their appearance, increase their resistance to wear and tear, and improve their overall performance.

- Q: Can aluminum sheets be etched or engraved?

- Indeed, it is possible to etch or engrave aluminum sheets. The process entails removing a portion of the material from the surface by utilizing acid or a laser with substantial power. This technique allows for the creation of detailed designs, patterns, or even textual elements on the aluminum sheet. The applications for etching or engraving are diverse, including signage, decorative items, and industrial components. To achieve the desired appearance, color or other finishes can be added to further enhance the resulting design on the aluminum sheet.

- Q: Can the aluminum sheets be used for manufacturing door frames?

- Indeed, door frames can be manufactured using aluminum sheets. Aluminum, a versatile material, finds extensive usage in the construction field owing to its robustness, longevity, and lightweight nature. It can be conveniently molded, curved, and joined through welding processes to fashion door frames of diverse dimensions and styles. Furthermore, aluminum possesses exceptional resistance against corrosion, rendering it suitable for both indoor and outdoor applications. In conclusion, employing aluminum sheets for the production of door frames represents a sensible and widely favored option within the construction sector.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is a versatile and efficient method that can be used to cut a wide range of materials including aluminum. By using a high-velocity jet of ionized gas, known as plasma, the aluminum sheet can be precisely cut into the desired shape. Plasma cutting offers numerous advantages such as faster cutting speeds, cleaner cuts, and minimal heat-affected zones compared to traditional cutting methods. It is commonly used in various industries such as automotive, aerospace, and construction for cutting aluminum sheets of different thicknesses.

- Q: How does aluminum sheet perform in outdoor applications?

- Aluminum sheet performs exceptionally well in outdoor applications due to its inherent corrosion resistance and durability. It is highly resistant to rust and can withstand exposure to harsh weather conditions, making it ideal for outdoor structures, signage, and cladding. Additionally, aluminum sheets can be coated or painted to enhance their weather resistance and aesthetic appeal. Overall, aluminum sheet is a reliable and long-lasting material for various outdoor applications.

Send your message to us

Mill Finish Aluminum Sheet AA1100 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords