Mill Finish Aluminum Sheets Florida AA1100 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet Alloy AA1100 for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet Alloy AA1100 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet Alloy AA1100 for Curtain Wall

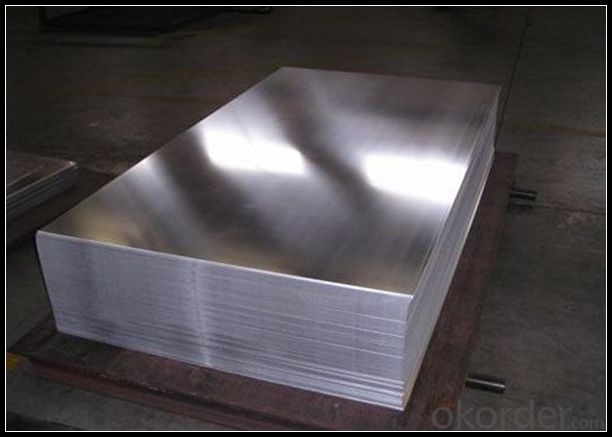

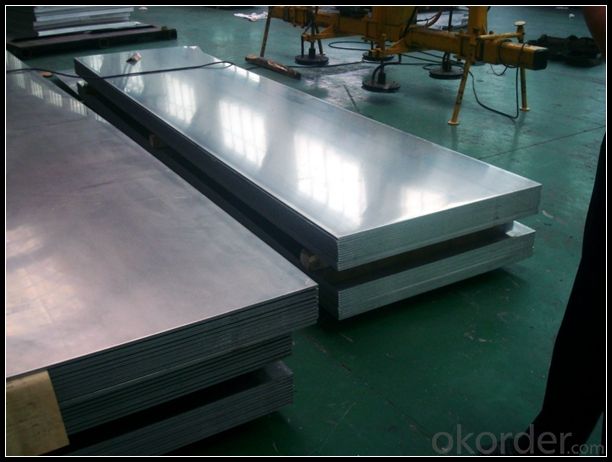

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

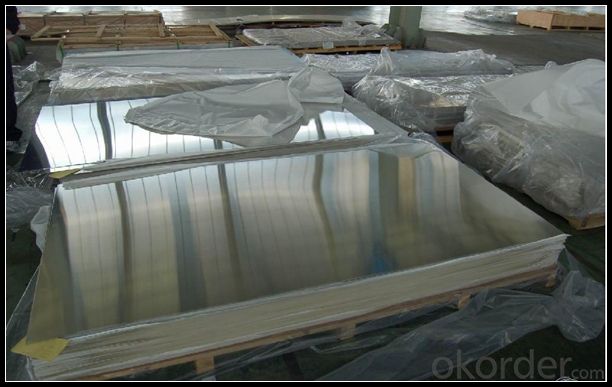

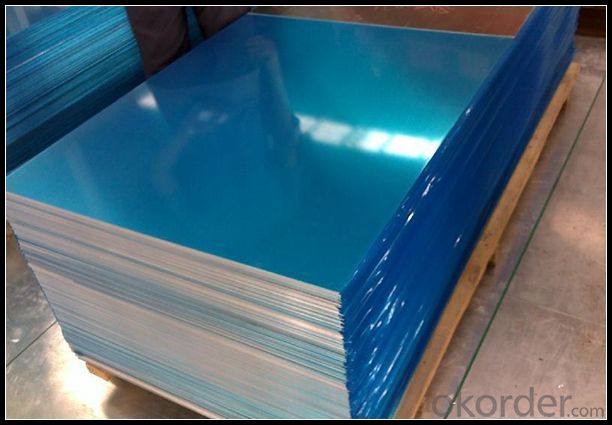

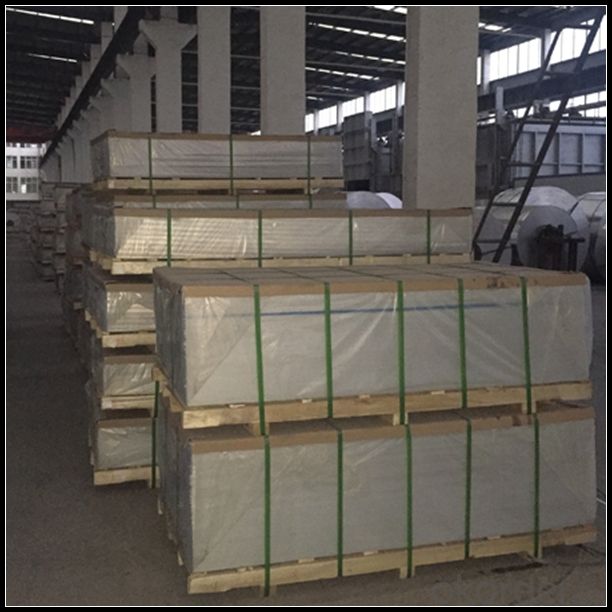

5. Image of Mill Finish Aluminium Sheet Alloy AA1100 for Curtain Wall

6. Package and shipping of Mill Finish Aluminium Sheet Alloy AA1100 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are suitable for signage. They are lightweight, durable, and weather-resistant, making them a popular choice for outdoor and indoor signage applications. Additionally, aluminum sheets can be easily customized, printed, and mounted, allowing for versatile and long-lasting signage solutions.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- The aluminum oxide that forms adheres to the metal surface explains aluminum's resistance to corrosion. Aluminum naturally forms a protective oxide film, which is stable in aqueous media when the pH is between about 4.0 and 8.5. The oxide film is naturally self-renewing and accidental abrasion or other mechanical damage of the surface film is rapidly repaired. The conditions that promote corrosion of aluminum and its alloys, therefore, must be those that continuously abrade the film mechanically or promote conditions that locally degrade the protective oxide film and minimize the availability of oxygen to rebuild it.

- Q: Can aluminum sheets be used for balcony railings?

- Indeed, balcony railings can be constructed using aluminum sheets. Aluminum is widely favored for balcony railings because of its lightweight properties, durability, and resistance to corrosion. This adaptable material can be effortlessly molded into various shapes and designs, making it suitable for a range of architectural styles. Moreover, aluminum railings necessitate minimal upkeep and can endure inclement weather conditions, rendering them an astute and enduring selection for balcony railings.

- Q: Are aluminum sheets suitable for electrical conductors?

- Aluminum sheets are indeed suitable for electrical conductors. They are frequently employed as conductors in a variety of electrical applications due to their remarkable conductivity, lightweight nature, and relatively low cost in comparison to metals such as copper. With approximately 61% of copper's conductivity, aluminum serves as an efficient conductor for most electrical purposes. Power transmission lines, electrical wiring, bus bars, and numerous other electrical components commonly utilize aluminum sheets. However, it is crucial to acknowledge that aluminum possesses higher resistance than copper, necessitating larger cross-sections to carry the same current. Additionally, caution must be exercised to prevent overheating when employing aluminum sheets as electrical conductors, as they have a lower melting point than copper.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: What is the corrosion resistance of 101 aluminum sheets in saltwater environments?

- 101 aluminum sheets are widely acknowledged to have excellent corrosion resistance in saltwater environments. Aluminum possesses inherent resistance to corrosion and when it encounters saltwater, it develops a protective oxide layer on its surface, which enhances its resistance to corrosion. This oxide layer functions as a shield, obstructing direct contact between the saltwater and the underlying metal, thereby decelerating the corrosion process. Nevertheless, it is crucial to acknowledge that prolonged exposure to saltwater can still result in some level of corrosion over time. Employing regular maintenance and applying protective coatings can significantly augment the corrosion resistance of 101 aluminum sheets in saltwater environments.

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets are significantly lighter than steel sheets, as aluminum has a lower density compared to steel.

- Q: 1100 scope of application of aluminum plate

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment

- Q: Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a popular material choice for food packaging due to its unique properties. It is lightweight, flexible, and has excellent barrier properties, which means it can effectively protect food products from moisture, light, oxygen, and other external contaminants. Aluminum sheets are commonly used for packaging various food items such as beverages, canned goods, ready-to-eat meals, and snacks. Additionally, aluminum is also recyclable, making it an environmentally friendly choice for food packaging.

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that offers several advantages for sculpting purposes. Firstly, it is lightweight, making it easier to handle and manipulate. This allows artists to create intricate and detailed sculptures without compromising on structural integrity. Additionally, aluminum is highly malleable, meaning it can be shaped into various forms and contours. This allows artists to experiment with different designs and achieve the desired artistic expression. Furthermore, aluminum is resistant to corrosion and weathering, making it ideal for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and retain its aesthetic appeal over time. Additionally, aluminum sheets can be easily welded or joined together, enabling artists to create larger and more complex sculptures. Overall, aluminum sheets provide artists with a flexible and durable material that allows for creativity and longevity in their sculptural works.

Send your message to us

Mill Finish Aluminum Sheets Florida AA1100 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords