POLISHED ALUMINIUM PLATES FOR MOLD PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

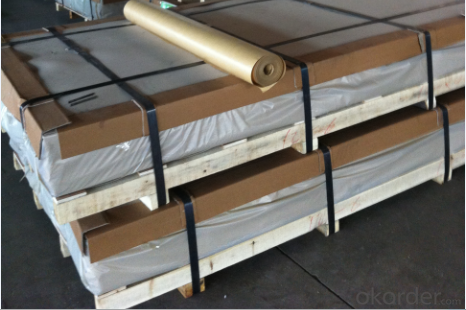

1.Structure of Product Description:Polished aluminium sheets 6061 for mold production

2. Our Strength:

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

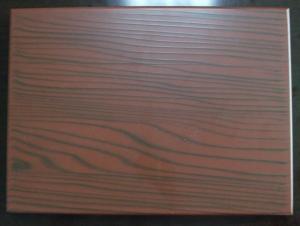

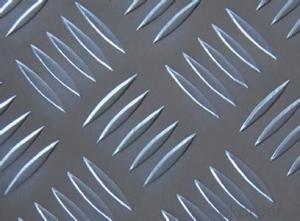

3. Image:

4. Common Specification

1000mm*2000mm, 1500*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets can be used in the aerospace industry. Aluminum is a lightweight material with excellent strength-to-weight ratio, making it a popular choice for various aerospace applications. It is commonly used in the construction of aircraft structures, such as fuselages, wings, and panels. The use of aluminum sheets in the aerospace industry offers several benefits, including reduced fuel consumption due to the weight savings, improved maneuverability, and increased payload capacity. Additionally, aluminum exhibits good corrosion resistance, which is crucial for aircraft exposed to harsh environmental conditions. Overall, aluminum sheets are widely utilized in the aerospace industry for their favorable properties and performance.

- Q: What are the necessary safety measures to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, it's crucial to wear appropriate personal protective equipment (PPE), including gloves to prevent cuts and eye protection to shield against flying debris. Ensure good ventilation to avoid inhaling dust or fumes from cutting or polishing. Use sharp tools to minimize the risk of accidents and always cut away from your body. Keep the work area clean and free of clutter to prevent slips or trips. Be cautious of electrical hazards if using power tools, and ensure all tools are properly grounded. Finally, be aware of the fire hazard potential of aluminum dust and store it safely away from ignition sources.</p>

- Q: This question asks for methods to determine the reliability of a supplier for aluminum sheets.

- <p>To determine if your supplier is reliable for supplying aluminum sheets, consider the following: Check their track record and customer reviews for consistency and quality. Assess their industry certifications, such as ISO standards, which indicate commitment to quality management. Evaluate their supply chain transparency and their ability to meet delivery timelines. Look into their financial stability to ensure they can sustain operations. Request samples to test the quality of their aluminum sheets. Finally, communicate openly with them to gauge their responsiveness and professionalism.</p>

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot can vary depending on the thickness or gauge of the sheet. On average, a 1/8 inch thick aluminum sheet weighs around 1.9 pounds per square foot. However, thinner sheets may weigh less, while thicker sheets can weigh more. It is important to consider the specific thickness of the aluminum sheet when determining its weight per square foot.

- Q: I need to fix some connections at my dad's house. The original wiring is aluminum, but the newer stuff he did is copper. Simple wire nuts will not suffice. Already had one melted one. I need to fix the connections, but need an economical, safe way of doing it. Suggestions?

- Replace all the wires into copper. Risk of fire as copper joints with aluminum or cause intermittent problem use on heavy current load. Because copper twists joint with aluminum create thermo effect. Aluminum wire was abandoned for house wiring long long time ago.

- Q: What type of aluminum plate does the traffic sign use? 1100?

- Model is not important, can meet the standard requirements on the line!

- Q: I have seen some stainless steel rifles that you can basically dunk in water, require no cleaning, etc and perform time after time. If SS is so good why are most weapons made of aluminum parts which is then anodized coated black? If you dunk these weapons in water will they rust? Thanks

- Their is no such thing as a corrosion proof metal. It's just corrosion resistant. Some more than others. And regardless it's going to have to be cleaned. When it comes to parts being made out of aluminum instead of steel it boils down to basically weight. Weight saving is a big thing nowadays and while aluminum is up to 5X more expensive its also 3x lighter. Also most aluminum parts on firearms are either low or no stress. Any high stress parts such as the bolt, chamber and barrel has to be made from a steel. No getting around it as aluminum wears out from those types of stresses faster.

- Q: bending, bending phenomenon will occur, I would like to annealing treatment. Does the master know the annealing temperature and time?

- Please call 0379-68311128 for technical consulting division wangke.

- Q: How much do aluminum sheets typically weigh?

- Aluminum sheets typically weigh between 1.9 to 3.4 grams per square centimeter, depending on the thickness and size of the sheet. The weight of aluminum sheets can vary significantly based on their dimensions and gauge. Thinner sheets generally weigh less, while thicker sheets tend to be heavier. It is important to note that the weight of aluminum sheets can also be influenced by factors such as the alloy used and any additional coatings or treatments applied to the surface. Therefore, it is advisable to consult the specific product specifications or reach out to the manufacturer for accurate weight information.

Send your message to us

POLISHED ALUMINIUM PLATES FOR MOLD PRODUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords