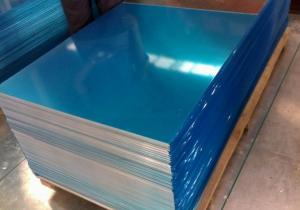

Aluminum Veneer Sheets - Aluminium Circle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

ALLOY:AA1***(AA1050,AA1070,AA1100etc)

AA3***(AA3003 etc)

TEMPER:O,H14

THICKNESS:0.5mm-4mm

DIAGONAL:100mm-1200mm

STANDARD:GB/T 3880-2006

Special specification is available on customer's requirement

- Q: Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

- Q: Are aluminum sheets suitable for construction purposes?

- Yes, aluminum sheets are suitable for construction purposes. They are lightweight, durable, and resistant to corrosion, making them ideal for various construction applications such as roofing, cladding, and structural components. Additionally, aluminum sheets offer good thermal and electrical conductivity, making them suitable for applications where these properties are required.

- Q: Do 101 aluminum sheets have any specific sound or vibration damping properties?

- Yes, 101 aluminum sheets have specific sound and vibration damping properties. Aluminum is known for its high damping capacity, which means it can effectively reduce vibrations and dampen noise. The specific properties of 101 aluminum sheets make them excellent choices for applications where sound and vibration control are desired, such as in the automotive and aerospace industries.

- Q: What does everyone think about replacing aluminum bats with wooded ones in high school. More and more cities are going back to wood.........why

- I always say I'm from the times of iron men and wooden bats, so I would love to see them go back. The advantage of metal is they last a lot longer, also they are easier to keep the weights consistant, and you don't kill any trees. The ball does come off the bat a lot hotter but they have been using them long enough that I don't think it's a safety issue. I think it has to do with making the transition back to wood if they are good enough to get that far.

- Q: Can aluminum sheet be used for aerospace structural components?

- Certainly, aerospace structural components can indeed utilize aluminum sheet. In the aerospace industry, aluminum is widely employed owing to its advantageous characteristics, including a high strength-to-weight ratio, resistance to corrosion, and excellent formability. By using aluminum sheet for these structural components, it becomes possible to construct aircraft that are lightweight, a crucial factor for optimizing fuel efficiency and performance. Moreover, aluminum is readily accessible and cost-effective, making it a favored option for aerospace applications. Nevertheless, it is worth mentioning that the selection of the aluminum sheet's specific grade and thickness will depend on the precise requirements and specifications of the aerospace structural component.

- Q: Are 101 aluminum sheets suitable for chemical processing environments?

- Yes, 101 aluminum sheets are suitable for chemical processing environments. 101 aluminum is a commercially pure aluminum alloy that offers good corrosion resistance and excellent weldability. It is often used in applications where high corrosion resistance is required, such as chemical processing plants. Additionally, 101 aluminum sheets can be further protected by applying a protective coating or anodizing process, which enhances their resistance to chemicals. Overall, 101 aluminum sheets are a suitable choice for chemical processing environments due to their corrosion resistance and ability to withstand exposure to various chemicals.

- Q: Can aluminum sheets be used for heat lamps?

- Indeed, heat lamps can utilize aluminum sheets as they possess remarkable heat conductivity. This quality enables aluminum to efficiently transmit and disperse heat, rendering it suitable for heat lamps that necessitate proficient heat distribution for effective warming of objects or spaces. Furthermore, the lightweight nature, durability, and high melting point of aluminum make it a practical and sensible option for heat lamp purposes.

- Q: I am ultimately looking to have a bike that is good for both everday commuting and touring with panniers/racks long distance with camping. From what I've read on the internet steel frames are more forgiving and ride smoother. The guy at my local bike shop tells me aluminum frames have more flex and ride better. I don't know if he's just trying to make a sale (Giant dealer) or to trust him, unfortunately the staff there are all just racers not tourers. If you can recommend any brands/models to check out that'd be good. From my research thus far I am in love with Co Motion bikes, just not the price! I'm looking at $1000 max for a good touring bike. Thanks!

- The two previous bikes lack brazeons for rack mounts up front, so they don't seem suitable for heavy, loaded touring expeditions. But, I don't see any models by Giant that have front rack brazeons. Actually, their forks all appear to be carbon/composite. I agree that the Co-Motion products look great, but their prices do seem a bit high for a welded frame, even if it is made in the US. The Surly LHT would make an extremely rugged, steel tourer. But building it up to your desired specs would likely put you way over your limit.

- Q: Are the aluminum sheets suitable for manufacturing chemical storage cabinets?

- Indeed, chemical storage cabinets can be manufactured with aluminum sheets. Aluminum, being a robust and long-lasting material, exhibits corrosion resistance, thus making it an excellent choice for safeguarding chemicals. Its lightweight nature renders transportation and installation more convenient. Moreover, aluminum remains non-reactive with the majority of chemicals, thereby ensuring the safety of stored substances. In summary, the utilization of aluminum sheets offers a dependable and effective solution for the production of chemical storage cabinets.

- Q: How does the surface treatment affect the corrosion resistance of aluminum sheet?

- Enhancing the corrosion resistance of aluminum sheet is greatly influenced by its surface treatment. Aluminum itself possesses inherent corrosion resistance due to the formation of a thin oxide layer on its surface. However, this oxide layer may not always be sufficient in safeguarding the metal against aggressive environments or harsh conditions. To significantly improve the corrosion resistance of aluminum sheet, various surface treatments such as anodizing, chromating, or painting can be employed. Anodizing involves the creation of a controlled oxide layer on the aluminum's surface through an electrochemical process. This layer exhibits high resistance to corrosion and effectively protects the metal from various corrosive agents. On the other hand, chromating involves the application of a chromate conversion coating that forms a thin film on the aluminum surface. This coating acts as a barrier, preventing the penetration of corrosive substances and subsequent oxidation. Additionally, it enhances the adhesion of subsequent paint or adhesive layers. Painting is another commonly utilized surface treatment for aluminum sheets. By applying a paint layer, the metal is not only shielded from corrosion but also acquires an aesthetically pleasing finish. The paint functions as a physical barrier that safeguards the aluminum against moisture, chemicals, and other corrosive elements. The selection of the appropriate surface treatment depends on the specific application and the desired level of corrosion resistance. Anodizing is often preferred in construction, automotive, and aerospace industries as it provides exceptional corrosion protection and enhances the appearance of the metal. Chromating is commonly utilized in electrical and electronic applications, as it offers both corrosion resistance and electrical conductivity. Painting is suitable for applications where both aesthetics and corrosion protection are of equal importance, such as architectural elements or consumer products. In conclusion, the corrosion resistance of aluminum sheet is significantly influenced by its surface treatment. Anodizing, chromating, and painting all contribute to enhancing the protective properties of aluminum against corrosion, thereby extending its lifespan and ensuring its durability in various environments.

Send your message to us

Aluminum Veneer Sheets - Aluminium Circle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords