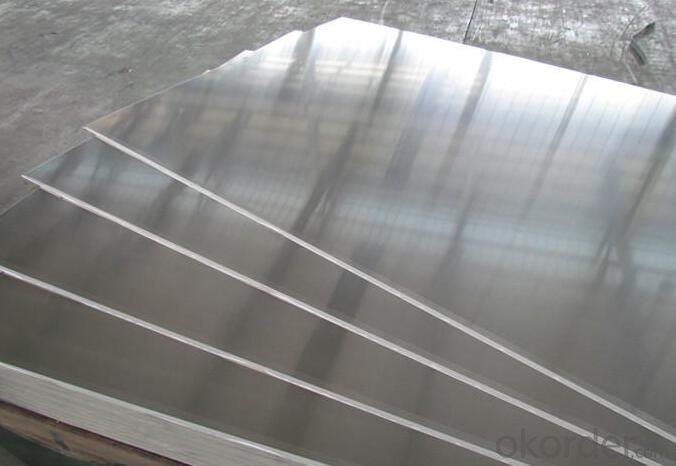

Mill Finish Aluminium Sheet for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Aluminium Sheet for Construction Material

1. Commodity: 5083 Aluminium Plain Sheet for Marine Use

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

4.Application:

1) air plane, refrigerators ,audio equipment

2)building materials: ceilings, walls

3)telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

1. | Item | Aluminum plate/ Aluminum sheet,aluminium plate price, aluminium chequer plate,aluminium sheet,aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060,1200,1100,a1100P,3003,3004,5052,5652,5154,5254,5454,5083, 5086,5056,5456,2A21,2024,2014,6061,6063,7072,7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~3000mm | ||

Length | 2m,3m,5.8m,6m,or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | MOQ | 500kg | |

12. | Export to | Singapore,Indonesia,Ukraine,Korea,Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq,Russia,Malaysia, etc. | |

13. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- plastic is more harmful when heated, they release dexoxin which is cancer causing. If you use them in micro ovens, its harmfull. Aluminum is much safer to cook in. It can with stand high temperatures.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: does aluminum sheet has a function of magnetism isolating?

- copper sheet is better.

- Q: What specific requirements or considerations are necessary when using aluminum sheets in marine environments?

- <p>In marine environments, aluminum sheets must meet specific requirements to ensure durability and resistance to corrosion. These include using high-grade aluminum alloys, such as 5083 or 5086, known for their excellent resistance to saltwater corrosion. Protective coatings like anodizing or applying marine-grade paints can further enhance corrosion resistance. Additionally, the aluminum sheets should be designed to withstand the harsh conditions of marine environments, including high humidity, UV radiation, and mechanical stress. Regular maintenance and inspection are also crucial to prevent corrosion and ensure the longevity of aluminum structures in marine settings.</p>

- Q: Can aluminum sheets be used for insulation?

- No, aluminum sheets alone cannot be used for insulation as they have low insulation properties. However, they can be used as a reflective layer in combination with other insulation materials to enhance insulation efficiency by reflecting heat or cold.

- Q: on the metal activity series, aluminum sits between magnesium and zinc, and all three sit above hydrogen. Explain why aluminum typically reacts only slowly with dilute acids even though both magnesium and zinc react rapidly

- Aluminum metal reacts with oxygen in the air to form a very tightly bonded aluminum oxide on its surface which slows the attack of acids trying to make contact with the aluminum atoms below the surface.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q: Are aluminum sheets suitable for heat sinks?

- Aluminum sheets are well-suited for heat sinks. They are a lightweight and highly conductive metal, making them a great choice for dissipating heat. With their high thermal conductivity, they efficiently transfer heat away from the source and distribute it over a larger surface area. Moreover, aluminum exhibits good corrosion resistance, which is crucial for heat sinks that may come into contact with moisture or other environmental elements. The flexibility and ease of working with aluminum sheets also allow for the creation of various heat sink designs to meet specific cooling needs. In summary, aluminum sheets are extensively employed in heat sink applications due to their exceptional thermal conductivity, lightweight nature, resistance to corrosion, and ease of fabrication.

- Q: Can 101 aluminum sheets be polished to a mirror-like finish?

- A mirror-like finish can be achieved on 101 aluminum sheets. Aluminum, being a lightweight and highly malleable metal, can be easily polished to obtain a reflective surface. Nevertheless, achieving a mirror-like finish on aluminum requires several steps and the use of appropriate polishing techniques and materials. To achieve a mirror-like finish on aluminum sheets, it is customary to begin by thoroughly cleaning the surface to eliminate any dirt, debris, or oxidation. Following that, sanding the surface with progressively finer sandpaper grits is necessary to eliminate imperfections or scratches. This step is vital in order to create a smooth and uniform surface that can be polished to a high level of shine. Once the sanding is completed, the polishing stage comes into play. There are various methods and materials available for polishing aluminum, such as abrasive compounds, buffing wheels, and polishing pads. These tools are utilized to exert pressure and friction on the aluminum surface, effectively removing any remaining scratches or imperfections and resulting in a smooth, reflective finish. Ultimately, to achieve a genuine mirror-like finish, the process of buffing or burnishing is often employed. This entails applying a polishing compound to the aluminum surface using a soft cloth or a specialized buffing wheel. The compound further refines the surface and enhances its reflective properties, ultimately leading to a mirror-like finish. It is important to note that achieving a mirror-like finish on aluminum can be a time-consuming and labor-intensive process, particularly when dealing with a large quantity of sheets like 101. Additionally, the quality of the aluminum sheets themselves and the skill level of the individual performing the polishing can also impact the final outcome. Nevertheless, with the right materials, techniques, and patience, it is indeed possible to polish 101 aluminum sheets to a mirror-like finish.

- Q: Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, architectural column covers can be manufactured using aluminum sheets. Aluminum is a material that is both lightweight and durable, offering excellent resistance to corrosion. This makes it an ideal choice for exterior applications like column covers. It is also easily shaped, bent, and fabricated, allowing for the creation of customized designs and sizes. This versatility is beneficial for architectural projects. Furthermore, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their visual appeal and provide extra protection against weathering and wear. Overall, aluminum sheets are a suitable option for manufacturing architectural column covers due to their combination of strength, versatility, and aesthetics.

Send your message to us

Mill Finish Aluminium Sheet for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords