Laserit Laserable Aluminum Sheets - Aluminum Sheet Diamante Embossed

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminum Sheet Diamante Embossed Description:

Our product is coated with high-performance fluorocarbon, polyester, polyurethane and epoxy coating, and is widely used for roofs, facade cladding, ceilings, aluminum curtains, composite panels, pipe wrap, advertisement plates, instrument panels, and other uses.

Main Features of the Aluminum Sheet Diamante Embossed:

Enviromental, light weight, waterproof, fireproof, anti-rust, weather resistance, easy cleaning, easy matching with other decoration materials...

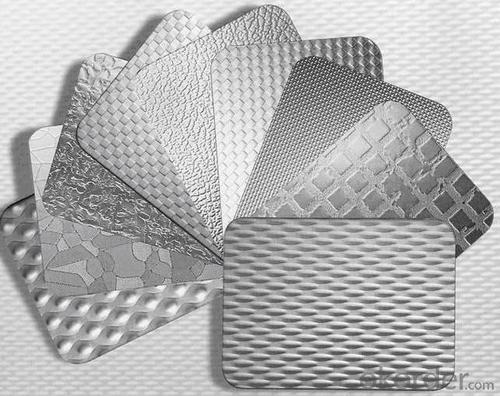

Images of Aluminum Sheet Diamante Embossed:

Aluminum Sheet Diamante Embossed Specification:

Other Product | Alloy | Temper | Thickness(mm) | Width (mm) | Length (mm) |

Aluminum tread plate | 1100 1050 1060 | O H12 H14 H16 H18 H22 H24 H26 H32 H36 H111 H112

| 0.2-200 | 40-1450 | As your requirement |

3003 3004 3005 3105 | |||||

5005 5754 5052 | |||||

5086 | |||||

6061 8011 |

FAQ of Aluminum Sheet Diamante Embossed:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: I've created a sculpture out of aluminum foil, but it's pretty flimsy. What can I paint or cover it with that would harden and support it? I was thinking a resin or something, but I have no experience with resins or epoxies... Any suggestions?

- you can use more aluminum and add layers to it. It would depend on the shape and size what is the best, but yes, you could use fiberglass and resin - as long as it is not so flimsy that the weight of the additional material will already distort it. If you just use resin that could work as long as it is reasonably flat, as the resin will run, but you could paint a number of thin coats on. Depending how it looks you could also use something like bondo which is car repair putty which is resin based. It might be easier to work with as it is thicker and it can be carved/sanded easily. Though you need to use it outside or with very good ventilation before it is set.

- Q: Is it possible to use aluminum sheets for constructing a sustainable building?

- <p>Yes, aluminum sheets can be used to create a sustainable building due to their recyclability, low thermal conductivity, and durability. Aluminum is a lightweight material that can reduce the energy consumption in transportation and construction. It also has a high recycled content ratio and can be easily recycled, which reduces waste. Additionally, aluminum's low thermal conductivity can contribute to energy efficiency in buildings by reducing heat transfer, thus lowering energy costs for heating and cooling. However, it's important to consider the entire life cycle of the material and ensure that the manufacturing and disposal processes align with sustainable practices.</p>

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Due to their lightweight, durability, and versatility, aluminum sheets are commonly used in architectural design and construction for applications such as cladding, roofing, facades, and decorative elements. They offer various finishes, patterns, and colors, making them suitable for enhancing the aesthetic appeal of both interior and exterior spaces. Additionally, aluminum sheets are resistant to corrosion and require minimal maintenance, making them a popular choice for decorative and architectural purposes.

- Q: I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- 3 square meters masses less than a gram - surely not But lets assume you have 0.995 grams. Dividing this number by 26.98(molar mass of AL) would give you moles of Al. Multiplying the number of moles X Avogadro's number (6.022 X 10^23) would give you atoms of Al. That number of atoms will cost you $2.96 . Dividing the cost by the total number of atoms will give you dollars per atom.

- Q: What are the common applications of aluminum sheets in construction?

- Due to their unique properties and versatility, aluminum sheets find various applications in the construction industry. Construction projects often utilize aluminum sheets for roofing, siding, cladding, windows, and doors. In roofing applications, aluminum sheets are ideal due to their lightweight yet durable nature. They can withstand harsh weather conditions, such as strong winds and heavy rainfall, without corroding or deteriorating. For siding applications, aluminum sheets are commonly chosen for their resistance to rust and corrosion. They not only provide protection but also enhance the overall appearance of buildings with an aesthetically pleasing finish. Furthermore, aluminum sheets can be easily shaped and bent to fit intricate or curved architectural designs. Cladding is another common use of aluminum sheets in construction. It serves to cover the exterior walls of buildings, providing insulation and protection against weather elements. By acting as a thermal barrier, aluminum cladding helps reduce energy consumption by keeping the interior cool in summer and warm in winter. It is also fire-resistant, making it a safe choice for construction projects. Moreover, aluminum sheets are frequently employed in the construction of windows and doors. Their lightweight nature makes them easy to handle and install, while their strength ensures durability and longevity. Additionally, aluminum sheets can be powder-coated or anodized, offering a wide range of color options to suit different architectural styles and preferences. In summary, aluminum sheets are commonly used in construction for roofing, siding, cladding, windows, and doors. Their lightweight, durable, and corrosion-resistant properties make them an excellent choice for various construction projects, providing both functional and aesthetic benefits to buildings.

- Q: why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q: What is the price range of 101 aluminum sheets?

- The price of 101 aluminum sheets can differ based on factors like thickness, size, and quality, leading to a variable price range. On average, each sheet can cost between $50 and $150. However, it is crucial to acknowledge that prices may differ among suppliers and retailers. To secure the optimal deal, it is advisable to compare prices from multiple sources.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Certain applications can consider aluminum sheets as an alternative to glass. Aluminum sheets provide various benefits over glass, making them suitable for specific scenarios. To begin with, aluminum sheets possess lightweight and durable characteristics, making them an excellent choice for industries like aerospace or automotive, where weight is a concern. Conversely, glass is relatively heavy and brittle, limiting its usage in certain environments. Moreover, aluminum sheets exhibit exceptional resistance to corrosion, making them a suitable option for marine or coastal applications, where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also possess a high strength-to-weight ratio, enabling greater design flexibility and structural integrity compared to glass. Furthermore, aluminum sheets offer superior thermal insulation properties in comparison to glass. They provide improved resistance to heat transfer, which is advantageous in applications where temperature control is crucial, like the construction industry. Additionally, aluminum sheets can be more cost-effective than glass in specific applications. The production and installation costs of aluminum sheets are often lower than glass, making them a more economical choice for large-scale projects. However, it is important to acknowledge that glass retains its own unique properties and advantages, such as transparency and optical clarity. Glass also has better resistance to scratches and chemical corrosion when compared to aluminum sheets. In conclusion, while aluminum sheets can serve as a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the final decision between the two materials depends on the specific requirements and limitations of the application at hand.

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To ascertain the thickness tolerance of an aluminum sheet, one must take into account several factors. Initially, it is crucial to refer to the industry standards and specifications for aluminum sheets. These standards typically offer guidelines and tolerances for different thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Subsequently, it becomes essential to utilize precise measuring equipment such as calipers or micrometers to precisely measure the thickness of the aluminum sheet. Multiple measurements should be taken at various locations on the sheet to account for any potential discrepancies. Once the measurements are acquired, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance generally represents the acceptable range in which the actual thickness of the sheet can deviate. For instance, if the specified thickness tolerance is ±0.002 inches, it signifies that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is deemed to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In certain instances, it may be necessary to consult with the aluminum sheet's manufacturer or supplier to determine the specific tolerance requirements for a particular application. They can offer additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet fulfills its intended purpose. All in all, the determination of the thickness tolerance of an aluminum sheet involves adhering to industry standards, employing accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This process guarantees that the sheet meets the required specifications and can be effectively utilized in diverse applications.

- Q: What's the difference between 6061 aluminum plate, 7075 aluminium plate and 6063 aluminum plate?

- Simply put, 6061 and 6063 belong to the 6 series, 6061 hardness in 90HB 6063 in 80HB, suitable for brazing, surface oxidation treatment is better, 7075 T6 hardness in 150HB, hardness is highestUsually 6061 and 6063 can be common

Send your message to us

Laserit Laserable Aluminum Sheets - Aluminum Sheet Diamante Embossed

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords