Hot Rolled MS Mild Heavy Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled MS Mild Heavy Steel Rails for Mines at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

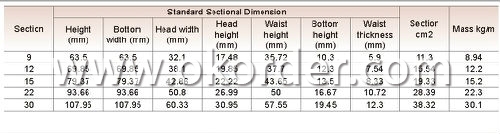

Product Specifications:

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How to judge whether the joint of steel structure is rigid or hinged, as shown below, the steel beam and steel column are all channel steel and welded through weld joint.

- A hinge: as the name suggests, the theory is completely unable to bear joint moment, and generally cannot be used for splicing component connection; hinged joints are usually only used for connecting end members, such as the end of the column and beam connections.

- Q: Can steel channels be used for supporting overhead cranes?

- Indeed, overhead cranes can be supported by steel channels. Due to their strength and durability, steel channels are frequently utilized in the construction sector. They serve as a dependable and sturdy support system for overhead cranes, which are utilized in industrial environments for heavy lifting. By engineering and installing the steel channels correctly, they can effectively withstand the weight and stress exerted by the overhead cranes, thereby guaranteeing safe and efficient operation. Moreover, steel channels can be readily customized and fabricated to meet the specific demands of a project, rendering them a versatile option for supporting overhead cranes.

- Q: Are steel channels suitable for use in agricultural applications?

- Yes, steel channels are suitable for use in agricultural applications. Steel channels have several characteristics that make them ideal for agricultural use. First and foremost, steel channels are strong and durable, providing excellent structural support. This is essential for agricultural applications where heavy loads or equipment may be involved. Furthermore, steel channels are highly resistant to environmental factors such as corrosion, rust, and weathering. This is particularly important in agricultural settings, where exposure to various weather conditions and chemicals is common. The durability of steel channels ensures long-lasting performance, reducing the need for frequent replacements or repairs. Additionally, steel channels are versatile and can be easily customized to meet specific agricultural requirements. They can be cut, welded, and shaped to suit different dimensions and configurations. This flexibility allows for easy installation and integration into various agricultural structures, such as barns, sheds, fences, and equipment. Moreover, steel channels offer fire resistance, which is crucial in agricultural applications where fire hazards exist, such as in storage facilities or near machinery. Steel's inherent fire-resistant properties help protect the agricultural infrastructure and minimize the risk of damage or loss. Lastly, steel channels are cost-effective in the long run. While the initial investment may be higher than alternative materials, the durability and low maintenance requirements of steel channels result in reduced repair and replacement costs over time. Overall, steel channels are an excellent choice for agricultural applications due to their strength, durability, resistance to environmental factors, versatility, fire resistance, and cost-effectiveness. These attributes make them suitable for a wide range of agricultural structures and equipment, providing reliable and long-lasting performance in the agricultural industry.

- Q: How do steel channels contribute to the versatility of a building design?

- Several factors contribute to the versatility of building design when using steel channels. Firstly, the exceptional strength and durability of steel channels enable them to bear heavy loads and withstand extreme weather conditions. Architects and engineers can confidently create innovative and intricate designs, knowing that the steel channels will provide the necessary structural support. In addition, steel channels are available in various sizes and shapes, providing flexibility in design. They can be manufactured to precise specifications, allowing for customization and adaptation to suit the unique requirements of each building project. This adaptability empowers architects to construct structures with different heights, spans, and configurations, maximizing space and generating visually captivating designs. The installation and assembly of steel channels are also simplified, streamlining the construction process. They can be effortlessly connected using different methods, including welding, bolting, or riveting, ensuring efficient and cost-effective construction. This ease of installation ensures that building projects are completed promptly, saving both time and resources. Moreover, steel channels are highly recyclable, making them an environmentally responsible choice for building designs. Steel can be recycled multiple times without compromising its inherent properties, reducing the demand for new raw materials and minimizing waste. This sustainable aspect of steel channels aligns with modern environmental standards and promotes eco-conscious construction practices, further enhancing the overall versatility of building designs. To summarize, steel channels enhance the versatility of building design through their strength, durability, customization options, ease of installation, and sustainability. By incorporating steel channels into their projects, architects and engineers can push the boundaries of design, create distinctive structures, and meet the diverse needs of their clients and communities.

- Q: Are steel channels suitable for agricultural equipment?

- Yes, steel channels are suitable for agricultural equipment. Steel channels are commonly used in the construction of agricultural machinery and equipment due to their strength, durability, and versatility. They provide excellent support and structural integrity, making them ideal for applications where heavy loads and harsh working conditions are involved. Steel channels also have a high resistance to corrosion, which is crucial in the agricultural industry where exposure to moisture, chemicals, and other environmental factors is common. Additionally, steel channels can be easily customized and fabricated to meet specific requirements, making them a preferred choice for agricultural equipment manufacturers.

- Q: Can steel channels be used for playground equipment?

- Yes, steel channels can be used for playground equipment. Steel channels are often used in the construction industry for their strength and durability, making them suitable for use in playground equipment. They provide a sturdy and stable framework that can support the weight of children and withstand the wear and tear of regular use. Additionally, steel channels can be easily shaped and welded to create various structures and designs for playground equipment, such as slides, climbing frames, and swing sets. Their versatility and ability to withstand harsh weather conditions make them an ideal choice for playground equipment that needs to be long-lasting and safe for children to use.

- Q: Are steel channels suitable for use in high-temperature environments?

- Depending on the type of steel and temperature range, steel channels can be utilized in high-temperature settings. Certain steels, like carbon steels, might experience diminished strength and ductility at high temperatures, rendering them unsuitable for particular applications. However, heat-resistant steels, including stainless steels and alloy steels, are specifically engineered to endure high temperatures without significant weakening or deformation. These heat-resistant steels can maintain their mechanical properties even at elevated temperatures, making them suitable for deployment in high-temperature environments. To determine the appropriate steel type and grade for a specific high-temperature application, it is crucial to seek advice from experts or refer to applicable standards and guidelines.

- Q: How do steel channels hold up against extreme temperatures?

- Steel channels are known for their exceptional strength and durability, making them highly capable of withstanding extreme temperatures. The properties of steel, such as its high melting point and thermal conductivity, allow steel channels to maintain their structural integrity even when exposed to extreme heat or cold. When subjected to high temperatures, steel channels expand at a slower rate compared to other materials, which helps to minimize the risk of deformation or failure. This resistance to thermal expansion is due to the low coefficient of linear expansion of steel. This property ensures that steel channels maintain their shape and structural stability even under extreme temperature fluctuations. Furthermore, steel channels possess excellent fire resistance. Steel has a high melting point, typically ranging from 1370°C to 1530°C (2500°F to 2800°F), which means it can withstand intense heat without losing its structural integrity. This makes steel channels a reliable choice in applications where fire protection is crucial, such as in buildings, bridges, or industrial structures. On the other hand, steel also exhibits good performance in cold temperatures. Unlike some materials that become brittle or weak when exposed to low temperatures, steel retains its strength and ductility. This makes steel channels suitable for use in environments with extremely cold temperatures, such as in arctic regions or cryogenic facilities. In conclusion, steel channels are highly resilient to extreme temperatures due to their low coefficient of linear expansion, high melting point, and overall durability. Whether exposed to intense heat or cold, steel channels maintain their structural integrity and provide long-lasting performance, making them a reliable choice in various applications.

- Q: Are steel channels suitable for use in piping systems?

- Steel channels are not suitable for use in piping systems. They are primarily intended for structural support or framing in construction projects and are not designed to withstand the pressure and flow of fluids in piping systems. Piping systems necessitate materials that are specially designed and tested to withstand high pressure, corrosion, and temperature fluctuations. Typical materials used in piping systems include steel pipes, copper pipes, and various types of plastic pipes that are specifically engineered for this purpose.

- Q: Can steel channels be used for balcony railings?

- Yes, steel channels can be used for balcony railings. Steel channels are strong and durable, making them suitable for providing support and safety on balconies. They can be customized to fit the specific dimensions and design requirements of the balcony. Additionally, steel channels are corrosion-resistant and can withstand harsh weather conditions, making them a reliable choice for outdoor applications. Whether it is for residential or commercial purposes, steel channels offer a versatile and aesthetically pleasing option for balcony railings.

Send your message to us

Hot Rolled MS Mild Heavy Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords