Hot Rolled MS Mild Light Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled MS Mild Light Steel Rails for Mines at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

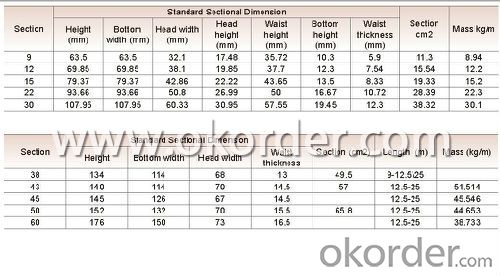

Product Specifications:

Product Name: High Quality Steel Rail

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel channels be used in the telecommunications manufacturing industry?

- Yes, steel channels can be used in the telecommunications manufacturing industry. Steel channels are commonly used in various industries, including telecommunications, due to their strength, durability, and versatility. In the telecommunications industry, steel channels can be used for various applications such as cable trays, support structures for antennas and satellite dishes, equipment racks, and enclosures. Steel channels provide a robust and reliable solution to support and protect telecommunications equipment and infrastructure. Additionally, steel channels can be easily fabricated and customized to meet specific requirements, making them suitable for the diverse needs of the telecommunications manufacturing industry.

- Q: What are they specifically connected to the bridge? Say more details!

- The channel is open type, angle "type, can be seen from the cross section, channel angle stronger than, of course, also a lot more expensive than the channel angle, if you are a fixed 400*100 below the bridge suggest you use the No. 4 angle on the line. If it is suggested that you use the steel suspension vertical wall, if the landing bracket I suggest you use the square.

- Q: How do steel channels perform in terms of fire resistance?

- Steel channels, also known as steel sections or steel beams, generally have good fire resistance properties. The fire performance of steel channels is influenced by several factors, including the grade and thickness of the steel used, the arrangement of the channels, and the fire protection measures applied. Steel, being a non-combustible material, does not contribute to the spread of fire. However, it does lose its strength at high temperatures. The rate at which steel loses its load-bearing capacity in a fire depends on the temperature and duration of the fire exposure. To enhance the fire resistance of steel channels, various fire protection measures can be applied. The most common method is to encase the steel channels in fire-resistant materials such as concrete or gypsum boards. This encasement acts as a barrier, slowing down the transfer of heat to the steel and providing insulation, thus prolonging the time it takes for the steel to reach critical temperatures. Additionally, steel channels can be coated with intumescent coatings or fire-resistant paints. These coatings expand when exposed to high temperatures, forming a protective layer that insulates the steel and delays its temperature rise. Overall, steel channels, when properly protected, can offer significant fire resistance. However, it is essential to consider the specific fire safety requirements of a structure and consult with fire protection experts or follow applicable building codes and standards to ensure adequate fire resistance measures are implemented.

- Q: The parameters of the channel steel of Q235B

- The execution standard is GBT706-2008 angle groove

- Q: Can steel channels be used for residential construction projects?

- Yes, steel channels can be used for residential construction projects. Steel channels are commonly used in construction due to their strength, durability, and versatility. They are often used for framing, support structures, and other applications in residential buildings.

- Q: Can steel channels be used in seismic design?

- Yes, steel channels can be used in seismic design. Steel channels are commonly used in seismic design to provide structural support and resist lateral forces that occur during an earthquake. They offer excellent strength and ductility, making them suitable for withstanding the dynamic loads and displacements experienced during seismic events. Additionally, steel channels can be easily fabricated and connected, allowing for efficient construction and flexibility in design.

- Q: Duplex 3, the main beam 3.6 meters, span 4.5 meters wide, steel structure, with 8 channel steel can be, how much space? Or how to make it reasonable? Daily life bears little weight.

- How reasonable?. Have to tell you the plane of the room, how to do it, according to some careful design, and then you see the satisfaction of the design results signed and approved. It'll take a lot of time. I can't help you.

- Q: What are the aesthetic options for steel channels?

- There are several aesthetic options available for steel channels, including different finishes such as polished, brushed, or painted surfaces. Additionally, steel channels can be customized with decorative patterns, textures, or etchings, providing further aesthetic choices.

- Q: What are the different methods of protecting steel channels from fire?

- There are several methods available to protect steel channels from fire. One common method is to apply a fire-resistant coating or paint to the surface of the steel channels. These coatings are designed to provide a protective barrier that can withstand high temperatures and prevent the steel from reaching its critical temperature, which is when it begins to lose its structural integrity. These coatings can be applied through various techniques such as spraying, brushing, or rolling. Another method is to encase the steel channels in fire-resistant materials such as concrete or gypsum board. This creates a physical barrier that insulates the steel from the heat of the fire, preventing it from reaching its critical temperature. This method is commonly used in construction projects where fire resistance is a critical requirement. Intumescent coatings are another effective method of protecting steel channels from fire. These coatings are specially designed to expand when exposed to high temperatures, forming an insulating char layer that protects the steel from the fire. Intumescent coatings can be applied as paints or sprays and are commonly used in buildings, particularly in areas where steel channels are exposed to fire risks. In addition to these methods, fireproofing materials such as fireproof wraps or blankets can be used to protect steel channels. These materials are typically made from fire-resistant fibers or fabrics and are wrapped around the steel channels to provide insulation and prevent the transfer of heat. Finally, proper fire safety measures such as installing fire suppression systems, smoke detectors, and fire alarms in the vicinity of steel channels can also help protect them from fire. These measures can help detect and control fires at their early stages, minimizing the risk of damage to the steel channels. Overall, there are various methods available to protect steel channels from fire, ranging from coatings and encasements to fireproofing materials and fire safety systems. The choice of method depends on factors such as the specific requirements of the project, the level of fire protection needed, and the budget constraints.

- Q: What is the minimum size of channel steel?

- Channel 5# channel, width of 50 mm, 37 mm high leg, thickness 4.5 mm.

Send your message to us

Hot Rolled MS Mild Light Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords