Injection Molding Machine LOG-250A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG250-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 464-785g

Clamping Force: 2500 kn

Opening Stroke: 520mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Screw Diameter: 50-58-65

Machine weight: 8 T

Material: Stainless Steel

Screw speed: 0-180 r/min

Function: Plastic Injection Molding Machinery

Space between Tie Bar: 560X530mm

Name: horizontal Injection Molding Machine

Ejector stroke: 150mm

Injection pressure: 132-224 mpa

Packaging Details: 20 GPcabinet

Delivery Detail: In one week after get payment

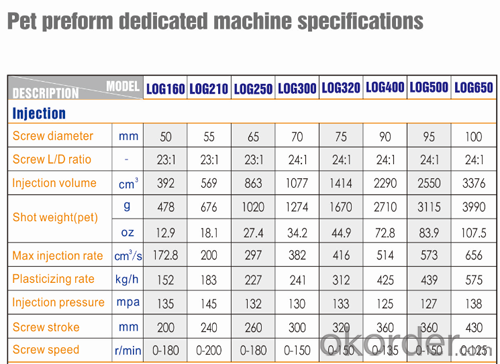

| LOG-250A8 | ||||

| International size rating | 1140/250 | |||

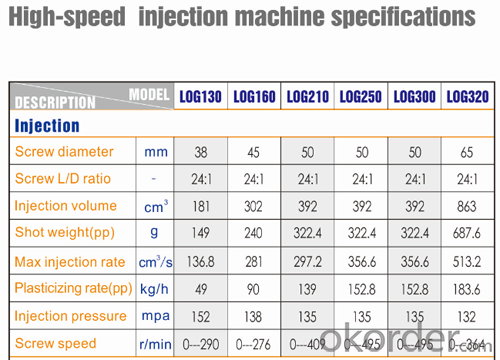

| INJECTION | A | B | C | |

| Shot volume | cm3 | 510 | 687 | 863 |

| Shot weight | G | 464 | 625 | 785 |

| OZ | 16.2 | 21.8 | 27.4 | |

| Screw diameter | mm | 50 | 58 | 65 |

| Injection pressure | mpa | 224 | 166 | 132 |

| Screw L:D ration | 21:01 | 21:01 | 18:07:01 | |

| Screw stroke | mm | 260 | ||

| Screw speed(stepless) | r/min | 0-180 | ||

| CLAMPING UNIT | ||||

| Clamping force | kn | 2500 | ||

| Opening stroke | mm | 520 | ||

| Platen size | mm×mm | 820×790 | ||

| Space between fie bars | mm×mm | 560×530 | ||

| Mold fhickness(Min-Max) | mm | 200-580 | ||

| Max.daylingt | mm | 1100 | ||

| Hydraulic ejection stroke | mm | 150 | ||

| Hydraulic ejection force | kn | 67 | ||

| POWER UNIT | ||||

| Hydraulic system pressure | mpa | 17.5 | ||

| Pump motor | kw | 22 | ||

| Heating capacity | kw | 16 | ||

| Number of femp confrol zones | \ | 5+ nozzle | ||

| GENERRL | ||||

| Dry-cycle fime | Sec | 4.8 | ||

| Oil fank capacify | λ | 380 | ||

| Machine dimensions | m×m×m | 6.2×1.6×2.15 | ||

| Machine weight | kg | 8000 | ||

product 1

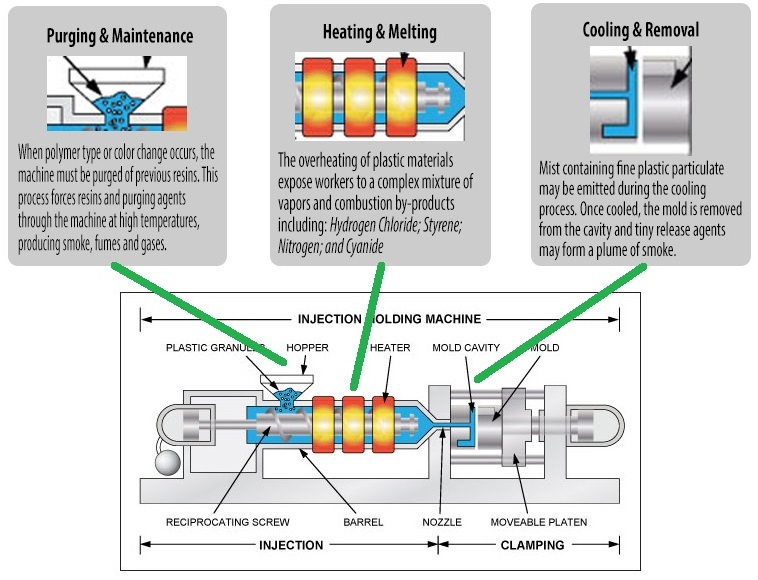

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

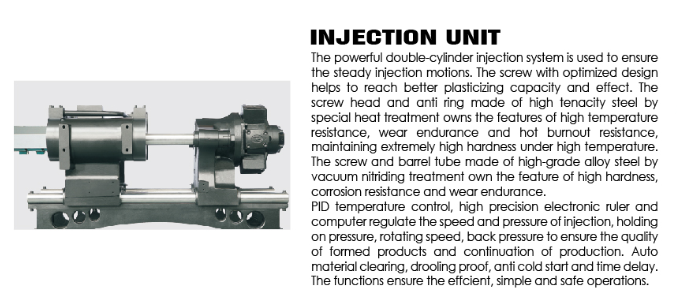

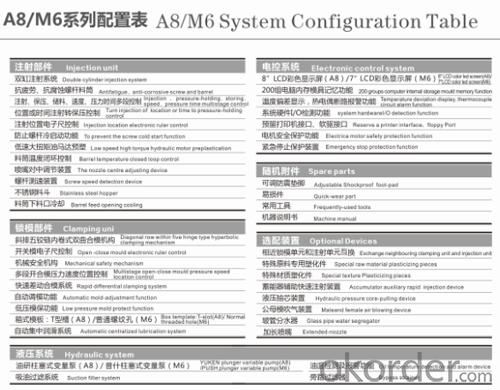

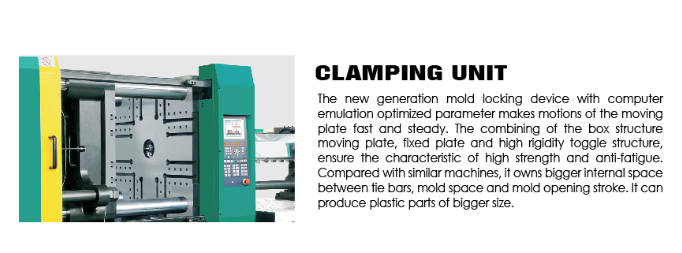

1 The mould closing unit

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate fast and steady .When combining the box type moving plate ,fixed plate and high rigidity toggle structure ,the characteristic of high strength and anti-fatigue is secured. As compared with similar machine , it owns bigger internal spur between tie bars ,mold space and mold opening storke and may process plastic product of bigger size.

2 Computer controller

professional injection molding machine controller with software abd hardware of industrial standard is convenient to expansion and revision of performance. Adopting double CPU control makes high speed.

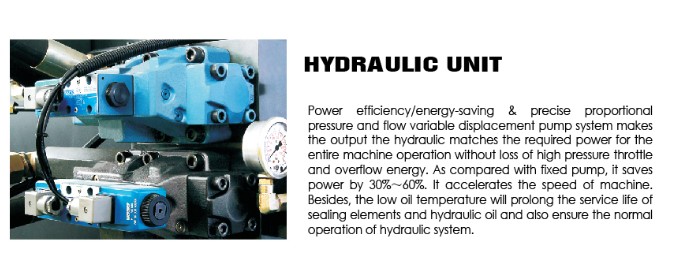

Variable Displacement Pump

1 Low Noise

Reasonable hydraulic control structure design, high integration and unipue processing in noise reduction helps machine run smoothly.

2 Oil-saving

The low oil temperature prolongs the srevice life of sealing elements .Oil cleaning equipment can filter the grease rapidly and effectively to ensure the srevice life of hydradulic elements.

3 Quick Response

The imported directly and high-response variable displacement pump achieves larger amount of emission by 20% to 25% than fixed pump driven the same motor.

4High Stability

30% to 70% energy saving compared with fixed pump under the equipment volume of work .

5 Water Saving

With no overflow and heating from variable displacement with fixed pump, 50%-75% water can be saved compared with fixed pump. Oil cleaning equipment is designed to improve the service life of hydraulic oil for 5 year.

- Q: Injection machine profile size

- The aperture of the nozzle (injection hole) is generally 2.2-2.5mm.

- Q: How do you increase your product? How do you assign multiple segments? Speed? How to determine the holding position? Big, good or small? All help answer! Be deeply grateful!

- The size of each of the products are different in nature, the machine method is not the same, increase the product I will generally use four, the first section of second section is walking the gate, go to watch it go gum products, is to prevent it, trapped gas or gas lines, third pressure faster than second some a little slower, the vantage point to almost full gum, last paragraph third paragraph is used as an outlet, the rate dropped to 10 or 15, the pressure to about 65, he shot to see which position began to pressure the pressure point is set to fourth position, if the material is difficult to shrink a good tune, put on three to Paul has shrunk, such as the first stage pressure 10, speed 15, 0.5 seconds, second pressure 20, speed 25, a second time, third pressure of at least 130 or more, the speed of not more than 45, at least 4 seconds If not, cut the amount of the first and second periods to control shrinkage. Of course there are sure to barrel temperature, mold temperature, get well, water or oil are related to important. I can answer that for you so far. Honestly, I've only been studying for 9 months so far. I've got everything to learn there. In fact, I want to be familiar with this line and practice more

- Q: how fast preheating ah, the more detailed the better, do not understand, please do not answer, online, etc.

- The best way to quickly preheat the oil temperature is to have heaters in the tank (much used in the North) + pressure preset (or repeated single action). Specific programs: boot, the tank temperature is lower than the working temperature of the lower limit, the heater work, at the same time, large flow pressure preset, working oil temperature until it reaches the lower limit, the heater stops working, the machine can carry out production.If you do not want to invest in this one, if you are the injection molding machine of asynchronous motor + quantitative pump (or pump), only pressure preset (or repeat a single action), by which the hydraulic system of heating, but relatively large energy consumption, and the oil temperature rise is not fast.If you have any questions, please feel free to ask them and hope to help you!

- Q: 4000 grams of injection molding machines, tons of sea and sky

- Haitian PL780 ton screw 120 injection volume is 4528 grams, 1000 tons B screw 4151 grams, C screw 4950 grams, D screw 5798 grams

- Q: General injection molding machine agents need what conditions?

- This is to ask manufacturers, each manufacturer of different

- Q: when the material stored, the screw has been in situ, and will not go back to the set stop position. What shall I do?

- There are several situations may lead screw rebate: 1, no material or hopper outlet plug; 2, the back pressure is too large, resulting in melt coming from the nozzle; 3, material additives or mineral oil too much, causing the screw slipping; 4, the screw is not smooth, with melt wrap screw, cannot be dissolved in your current temperature; 5, machine maintenance, reverse screw; and I hope to help you.

- Q: What is the injection molding machine?

- An injection molding machine is a mechanical device that fills a plastic into plastic!!

- Q: Want to know how to play a complete product, how to calculate the pressure, speed, etc.. Example, GREE electrical appliances series 4002B chassis, how can I transfer the full product?.

- The injection pressure and velocity are related to material selection, runner layout, gate form, melt temperature, and mold temperature. Moldflow software can be used to predict the filling, holding and cooling of plastic melts in the mold, and also to predict the possible defects.

- Q: Debugging and debugging process of injection molding machine

- (2) products shrinkFault reason handling methodInsufficient mold penetrationThe amount of melt is not enough, plus the amount of melt adhesiveLow glue pressure, low pressureHigh back pressure back pressure is not enoughInjection time too short injection timeInjection speed is too slow or fastThe overflow is uneven and the overflow of the mold is too small or in placeThe nozzle hole is too thin, plastic in the sprue bushing in solidification, reduce the back pressure effect. Adjust the mold or replace the nozzleMaterial temperature is too high and material temperature is lowImproper temperature and proper temperatureThe cooling time is not enough to prolong the cooling timeWhen the pressure storage section is too large, the adhesive shall terminate at the front endThe product itself or its ribs and columns are too thick to review the finished product designExcessive injection of glue to replace the finer injection molding machineWear removal of apron and adhesive screwGate is too small, plastic solidification loss, back pressure action, increase gate size

Send your message to us

Injection Molding Machine LOG-250A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords