High Quality Injection Molding Machine LOG-90A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OIL MOTOR : INTERMOT

DIRECTION VALVE: VICKERS

COMPUTER: MIRLE 9118

AC CONTACTOR : SCHNEIDER

ELECTRONIC RULER: NOVO

LUBICATION PUMP: HERG

| Model | UNIT | LOG-90A8 | |||

| International recognized model | 275/90 | ||||

| INJECTION | A | B | C | ||

| Shot volume | cm3 | 113 | 154 | 181 | |

| Injection | Shot weight | g | 106 | 144 | 170 |

| volume | |||||

| ps | Oz | 3.7 | 5.1 | 5.9 | |

| Screw diameter | mm | 30 | 35 | 38 | |

| Injection pressure | mpa | 243 | 179 | 152 | |

| Screw L:D ratio | 20:01 | 20:01 | 18:01 | ||

| Screw stroke | mm | 160 | |||

| Screw rotate speed | r/min | 0-180 | |||

| Clamping force | kn | 900 | |||

| Opening stroke | mm | 320 | |||

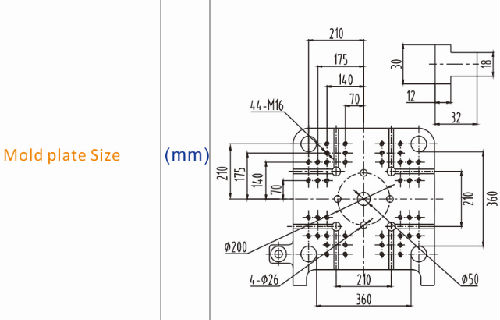

| Platen size | mm*mm | 540*540 | |||

| Space between tie bars | mm*mm | 360*360 | |||

| Mold thickness | mm | 150-360 | |||

| Platen Max stroke | mm | 680 | |||

| Ejection stroke | mm | 100 | |||

| Ejection force | kn | 31 | |||

| Hydraulic system pressure | mpa | 16 | |||

| Pump motor | kw | 9 | |||

| Heating power | kw | 6.5 | |||

| Number of temp.control | 3+射嘴(nozzle) | ||||

| Cycle time | sec | 1.1 | |||

| Oil tank capacity | L | 160 | |||

| Machine dimensions | m*m*m | 4.2*1.1*1.7 | |||

Products performance and advantages

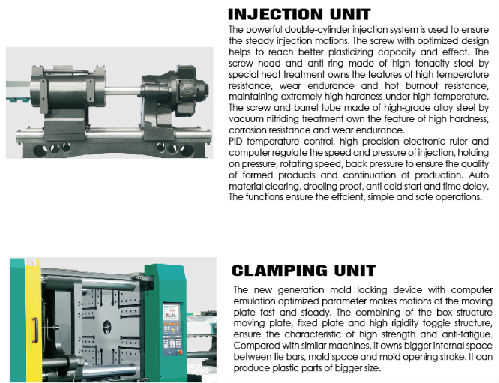

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

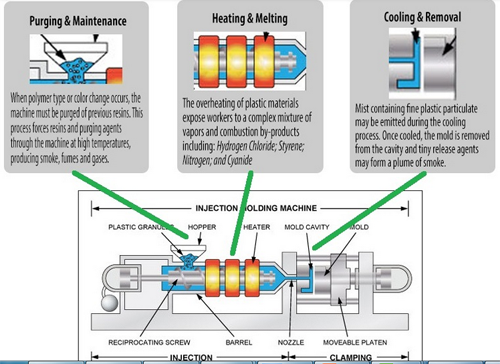

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

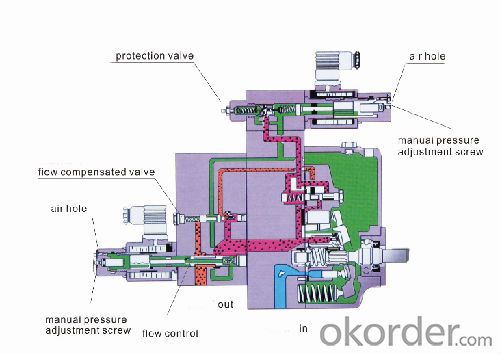

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

Products performance and advantages

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

Clamping system: Faster response, stable and high rigidity

Injection system: Accurate and flexible, lower rejection rate

Control system: Computer and simple operation,molding data memory system

Power system: Energy saving, high efficient and precise

Metal parts: The thickness of our frame, metal plate and wallboard are thicker than other company.

Other Information

Ceramic heating loop: Uniform heating, better thermal insulation properties so good for production

Visiable lubrication system: on time clean, avoid cast steel parts abrasion and broken.

Oil treasure: Filter of hydraulic oil,good for pump and valves

Long working life: Imported spare parts and updated version

Aftersales service: Professional & timely

Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Some vertical machines also don't require the mold to be fastened. There are many ways to fasten the tools to the platens, the most common being manual clamps (both halves are bolted to the platens); however hydraulic clamps (chocks are used to hold the tool in place) and magnetic clamps are also used. The magnetic and hydraulic clamps are used where fast tool changes are required.

The person designing the mold chooses whether the mold uses a cold runner system or a hot runner system to carry the plastic from the injection unit to the cavities. A cold runner is a simple channel carved into the mold. The plastic that fills the cold runner cools as the part cools and is then ejected with the part as a sprue. A hot runner system is more complicated, often using cartridge heaters to keep the plastic in the runners hot as the part cools. After the part is ejected, the plastic remaining in a hot runner is injected into the next part.

- Q: How to check the mold opening stroke of injection molding machine

- The mould opening stroke of the injection machine should meet the need of separating the mold and removing the plastic parts. The checking of mould opening stroke is divided into the following several situations.1. the maximum opening stroke of injection molding machine has nothing to do with the die thicknessMainly refers to the clamping mechanism for injection molding machine with hydraulic machinery, such as XS-Z-30, XS-Z-60, XS-ZY-125, XS-ZY-350, XS-ZY-500, XS-ZY-1000 and G54-S200/400 type injection molding machine, the mold opening stroke by the connecting rod mechanism (or clamping cylinder) determines the maximum stroke, irrespective of the thickness of the mold.For injection mold with single parting surface:Smax = H1+H2 + mm (5 ~ 10)For injection mold with double parting surface:Smax = H1 +H2 + +a (5 ~ 10) mmType: Smax injection molding machine maximum mold opening stroke (mm);H1 plastic parts (mm, H1) launched a distance - like mold core is equal to the height, but for the plastic parts of the inner surface is stepped, sometimes do not have to launch the full height core can remove the plastic parts, then H1 can be determined according to specific circumstances, in order to successfully remove the plastic parts;H2 a piece of plastic height, including the height of the castable (mm) of the gating system that is connected to the plastic part.A the distance between the fixed die seat plate and the runner plate required by the casting system to remove the condensate (mm).

- Q: How many solenoid valves are there on the injection molding machine?

- The working principle of solenoid valve, solenoid valve in a closed chamber, at different locations to open a hole, each hole leads to different pipeline, the middle valve chamber, both sides are two electromagnets, which face the magnet coils body will be attracted to which side, different row the oil control valve moves to block or leak hole, and an oil inlet hole Shichang opened, hydraulic oil will enter the drain pipes of different, then the oil pressure to push the piston oil just, piston and piston rod, the piston rod drive mechanism moving. Thus, the mechanical movement is controlled by controlling the electric current of the electromagnet. Cxmeinai.1688 , I hope I can help you!

- Q: How many moulds can the 80 ton injection molding machine put down?

- The machines of each brand are slightly different. The width is usually 350.

- Q: I want to study and maintain the injection molding machine, but I don't know whether it's difficult or not. What are the main points I should pay attention to when I study?

- Both imported and domestic injection molding machines have the following characteristics:And representatives of Jingxian County rubber hose enterprises attended the meeting. Mayor Gao Hongzhi attended the seminar and delivered a speech. Jingxian County is the birthplace of plastic pipe industry, great opportunities in recent years the county seize cars, coal, metallurgy, petroleum and other industries of China's rapid development, focusing on creating the first industry, the strongest and most characteristic industry, the author probes into many aspects of process principle, process flow, process, reaction the mechanism, adverse reaction and prevention and control measures, equipment, Manning, cost estimation, environmental protection, technical characteristics, product quality standards, can be used for domestic automotive hose technology reference to the development of this report;Oil or electric compound or local electric injection molding machine. Whether all electric or hybrid type belong to the category of electric injection molding machine injection molding machine, therefore, since the development of the plastic injection machine is all electric or electric part (hybrid) has aroused extensive discussion. More than the "full electrification" of the injection molding machine, especially the feeding structure, which is driven by an electric servo motor, is very common in injection molding machines in Germany and italy.

- Q: When the injection machine is ejected, does the screw screw rotate?

- We call it a battery, and I don't know what you call it

- Q: when the temperature rising in the exit but this is what the normal temperature increase of more than 20 degrees

- PVC for the temperature requirements are very strict, the back pressure is small, hard PVC temperature can not too low at about 170-190, too low, but not good, there is a delay melt, namely the screw does not move after injection, on the verge of opening a few seconds before time began to melt, melt after 10 seconds to stop the opening of concrete how much time delay according to the time you began to melt cooling and temperature control, there is a nozzle to just not cured so far, should not be too high. This basically can control the temperature, can be controlled within 8 degrees.

- Q: What is the best brand of injection molding machine?

- Domestic Haitian, Donghua, Huada, all can. Foreign Demag, Ube.

- Q: Debugging and debugging process of injection molding machine

- (2) products shrinkFault reason handling methodInsufficient mold penetrationThe amount of melt is not enough, plus the amount of melt adhesiveLow glue pressure, low pressureHigh back pressure back pressure is not enoughInjection time too short injection timeInjection speed is too slow or fastThe overflow is uneven and the overflow of the mold is too small or in placeThe nozzle hole is too thin, plastic in the sprue bushing in solidification, reduce the back pressure effect. Adjust the mold or replace the nozzleMaterial temperature is too high and material temperature is lowImproper temperature and proper temperatureThe cooling time is not enough to prolong the cooling timeWhen the pressure storage section is too large, the adhesive shall terminate at the front endThe product itself or its ribs and columns are too thick to review the finished product designExcessive injection of glue to replace the finer injection molding machineWear removal of apron and adhesive screwGate is too small, plastic solidification loss, back pressure action, increase gate size

- Q: Injection molding machine pressure, speed, back pressure unit is what and their relations with other international units

- Pressure injection molding machine, we often talk about the pressure, strictly speaking, the pressure is equivalent to the middle school, which bear the force per unit area, the international regulations, under 1N in the area of 1 square meters (Newton) on the pressure of 1Pa (Pascal), as long as know the multiple relation, it is easy to obtain the pressure (strong the conversion unit):1m=100cm=1000mm1kg = 10N1M (megabit, million) Pa=1MPa=1000k (1000) Pa=1000000PaSo 1MPa=10kg/cm^2=1N/mm^2We often use international non legal units of measurement: 1bar=10^5Pa=1kg/cm^2=0.1MPa (bar) and 1Torr=133Pa (Torr)The pressure gauge of the injection molding machine, the most used is MPa, bar, kgf/cm^2 unit, need to be reminded that, behind the two units is not our statutory units of measurement, but the world especially Europe and the United States is often used, because many components of the injection molding machine for imported components, including the pressure gauge, so we will often see illegal dial pressure gauge measurement units.In the injection molding machine, the injection molding machine pressure and back pressure unit is MPa, speed (actually refers to injection rate), the unit is g/s, or cm^3/s

- Q: How does the steel injection machine go to the origin?

- 3, with the clamping force of 15% of the set, if the spring die can not be completely closed, or want to reduce the mold contact time, in the range of +-10%, adjust the mold low pressure protection pressure. In the setting of clamping stroke, pressure mold protection must be set by the mold temperature reaches the set value can be accurately set a low voltage protection, because in the cold to be better at the mold temperature reaches the set value of thermal expansion is not locked. 6.2 after the set with A4 (40*40MM) A4 with butter wet paste in the mold safety parting surface, and then clamping voltage protection effect test. If after the mold, the machine will alarm, OK, otherwise reset the low voltage protection parameter until OK.This answer is recommended by users

Send your message to us

High Quality Injection Molding Machine LOG-90A8

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords