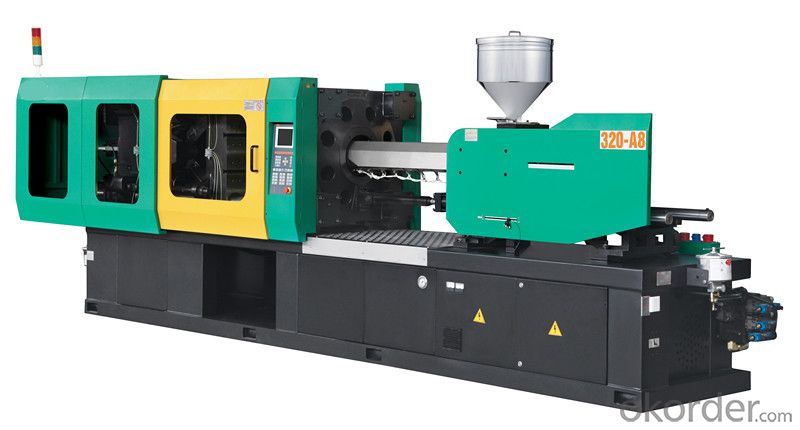

Injection Molding Machine LOG-320A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Condition: New | Place of Origin: China (Mainland) |

| Type: Tube Head Injection | Plastic Type: Thermoplastic |

| Style: Horizontal | Automatic: Yes |

| Brand Name: LOG | Injection Weight: 1120g |

| Model Number: LOG-320A8 | Clamping Force: 3200KN |

| Opening Stroke: 615mm |

Packaging & Delivery

| Packaging Details: | one machine in a 40 GP container |

|---|---|

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

1.high response 2. high precise 3.oil saving 4. water saving 5. long warking life

Details :

LOG-320A8 | ||||

International size rating | 1870/320 | |||

INJECTION | A | B | C | |

Shot volume | cm3 | 1062 | 1231 | 1414 |

Shot weight | G | 966 | 1120 | 1286 |

OZ | 33.7 | 39.2 | 44.9 | |

Screw diameter | mm | 66 | 70 | 75 |

Injection pressure | mpa | 175 | 152 | 133 |

Screw L:D ration | 21:1 | 21:1 | 19.6:1 | |

Screw stroke | mm | 320 | ||

Screw speed(stepless) | r/min | 0-150 | ||

CLAMPING UNIT | ||||

Clamping force | kn | 3200 | ||

Opening stroke | mm | 615 | ||

Platen size | mm×mm | 945×945 | ||

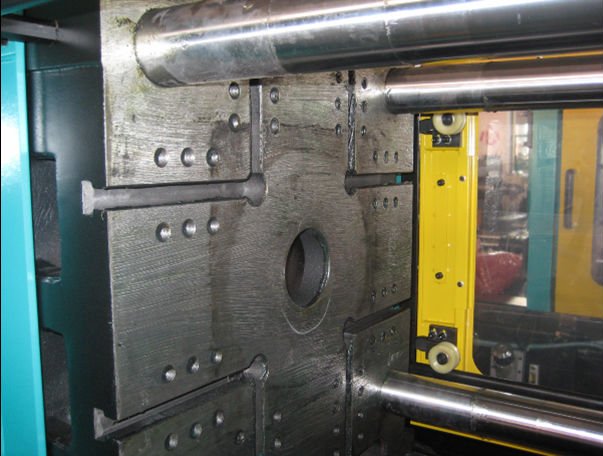

Space between fie bars | mm×mm | 660×660 | ||

Mold fhickness(Min-Max) | mm | 250-670 | ||

Max.daylingt | mm | 1285 | ||

Hydraulic ejection stroke | mm | 160 | ||

Hydraulic ejection force | kn | 77 | ||

POWER UNIT | ||||

Hydraulic system pressure | mpa | 17.5 | ||

Pump motor | kw | 30 | ||

Heating capacity | kw | 21.5 | ||

Number of femp confrol zones | \ | 5+ nozzle | ||

GENERRL | ||||

Dry-cycle fime | Sec | 5.0 | ||

Oil fank capacify | λ | 500 | ||

Machine dimensions | m×m×m | 8.6×1.58×2.25 | ||

Machine weight | kg | 13000 | ||

1.template structure of the high-rigidity design,with a bigger clamiping unit. 2. T- slots and conventional screw holes make mold is easy to install. 3 by using our patent bridge structure ,the injection unit will be more stable 4, equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water 5. high-efficiency filter makes the hydraulic oil clean and a long working life 6. the color screen control system, is conventional to operate it.

- Q: What is an injection molding machine?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment.Working principle:The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products. Injection molding is a cycle process, each cycle mainly include: quantitative feeding - melt plasticization - pressure, injection - filling mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle.

- Q: how fast preheating ah, the more detailed the better, do not understand, please do not answer, online, etc.

- Do not know you have no injection molding machine mold with mold temperature machine temperature control, if any, can do a coil in the fuel tank heat exchanger from the mold temperature machine connected to a set of loop heat exchange in a can to the mailbox.

- Q: How the elite injection molding machine sales in Southern China?

- Not how the elite injection molding machine is low, I used, not very easy to use. The quality is poor and the price is cheap

- Q: What is the injection molding machine back pressure, back pressure role is what?

- Adjustment of back pressureThe adjustment of the injection back pressure shall be determined according to the raw material performance, drying conditions, product structure and quality, and the back pressure should be adjusted at 3-15kg/cm 3. When the surface of the product has little Qihua, mixed color, shrink and product size and weight changes, may be appropriate to increase the back pressure. When the nozzle leakage glue, salivation, Melt Overheating product decomposition, discoloration and feeding back too slow may be considered appropriate to reduce the back pressure.Back pressure is one of the important parameters to control melt quality and product quality in injection molding process. Proper back pressure plays an important role in improving product quality, and can not be ignored!

- Q: We are going to an injection molding machine factory at once. I don't know yet which is what I learn, NC, please master, and hope to be able to put the knowledge about injection molding machine told me, I appreciate the injection molding machine is that NC programming ah | please master, thank you

- The value of the mold is realized by injection molding machine

- Q: What kind of metal material is the nozzle head of injection molding machine?

- Screw is an important part of injection molding machine. Its function is to transport, compact, melt, stir and press the plastic. All this is done by rotating the screw in the barrel. When the screw rotates, the plastic will cause friction and movement between the inner wall of the cylinder, the bottom of the screw, the bottom of the screw, the advancing surface of the screw and the plastic and plastic.Often used to produce screw material:1, 38CrMoAla2, SACM6453, 42CrMo4, 9Cr18MoV5, SKD616, tungsten carbide alloy, tungsten carbide nickel based alloy7 、 fully hardened powder alloy (Quan Hejin)8, high temperature alloy

- Q: What is the injection molding machine?

- That is simple, there is a machine, you put the granular materials into his mouth, it inside the particles melt into liquid, then the whole into the mold, the mold is filled, the liquid cooled to a solid, spit out your parts, such a machine is injection molding machine

- Q: For example, according to the shape, the injection quantity, clamping force, and electric, all electric ^^^ hope to get a more comprehensive answer Thank you!!!

- As the structure and types of injection molding products are relatively large, the injection molding machine used for molding injection products is also more. The injection machine is classified according to the following ways:1. classify the raw materials by plasticization and injection.2., according to the injection machine configuration, different classification.3. classification according to the processing capacity of injection molding machine.4. according to the special use of the injection machine classification.According to the classification of raw materials plasticizing and injection methods, the injection machine can be divided into: (1) plunger type, (2) reciprocating screw type and (3) screw, plasticizing plunger, injection type three.According to the structure of the injection machine, it can be divided into: (1) vertical injection molding machine, (2) horizontal injection machine, (3) angle injection machine, (4) multimode injection machine, (5) combined injection machine.According to the size of the processing capacity to the injection machine classification, can be divided into: (1) ultra small injection machine, (2) small injection molding machine, (3) medium-sized injection molding machine, (4) large injection machine (5) super large injection molding machine.By use of the injection machine can be divided into: (1) general injection machine, injection machine exhaust (2), (3) high speed precision injection machine, injection machine (4), (5) three plastic shoes injection head single mold injection machine, double head two (6) injection mould injection molding machine.

- Q: Domestic injection molding machine which brands are better?

- The sea, the Haida, the shock,High exposure... Shock bear, Iraq's secret, Bo Chuang, Donghua

- Q: What does the injection machine do?

- [injection molding machine] also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.The injection molding machine has the ability of a complex shape, size precision or with plastic metal inserts texture dense, is widely used in national defense, electronics, automotive, transportation, building materials, packaging, agriculture, education, health and daily life in various fields. In today's rapid development of plastic industry, plastic injection molding machine plays an important role both in quantity or variety, the total production of the plastic molding equipment 20%--30%, thus becoming the fastest growth in plastics machinery, one of the largest number of production model.

Send your message to us

Injection Molding Machine LOG-320A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords