Injection Molding Machine LOG-500A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Preform Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG-500A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 1919g

Injection Rate: <SPAN class=attr-value title=459cm3/s style="BORDER-RIGHT: 0px; PADDING-RIGHT: 0px; BORDER-TOP: 0px; PADDING-LEFT: 0px; PADDING-BOTTOM: 0px; MARGIN: 0px; VERTICAL-ALIGN: baseline; BORDER-LEFT: 0px; PADDING-TOP: 0px; BORDER-BOTTOM: 0px; FONT-FAMILY: inherit; WORD-WRAP: break-word; font-stretch: inherit">459cm3/s

Clamping Force: 5000KN

Opening Stroke: 780mm

After-sales Service Provided: Overseas third-party support available

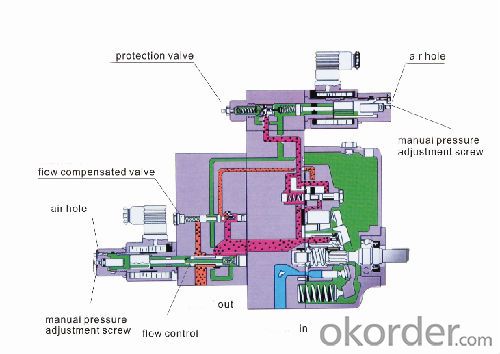

energy saving: oil saving

| Description | Unit | LOG-500A8 | ||

| international recognized models | 3240/500 | |||

| Injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 1590 | 2040 | 2550 |

| Shot volume | g | 1494 | 1919 | 2397 |

| Oz | 52.3 | 67.2 | 83.9 | |

| Screw diameter | mm | 75 | 85 | 95 |

| Injection diameter | mpa | 204 | 159 | 127 |

| Screw L:D ratio | 23.8:1 | 21:01 | 18.7:1 | |

| Scerw steoke | mm | 360 | ||

| Screw rotate speed | r/min | 0-150 | ||

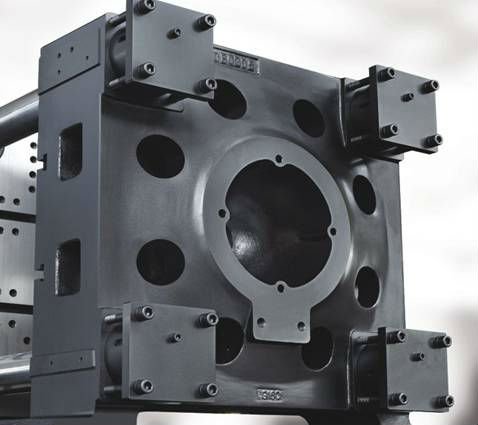

| CLAMPING UNIT | ||||

| Clamping force | kN | 5000 | ||

| Opening stroke | mm | 820 | ||

| Platen size | mm*mm | 1180*1180 | ||

| Space between tie bars | mm*mm | 830*830 | ||

| Maldthickness | mm | 300-820 | ||

| Platen Mix stroke | mm | 1600 | ||

| Ejection stroke | mm | 210 | ||

| Ejcetion force | kN | 111 | ||

| Power/Elcetric Heating | ||||

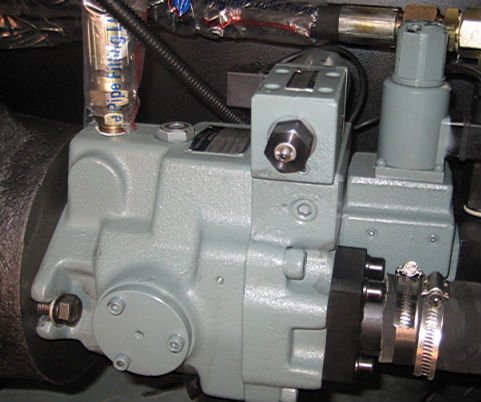

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7+29 | ||

| Heating power | kw | 42.5 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5.2 | ||

| Tank volume | L | 1150 | ||

| Machine dimesions | m*m*m | 9.2*1.85*2.41 | ||

| Weight of machine | kg | 22000 | ||

Packaging & Delivery

| Packaging Details: | one machine in a 40GP container |

|---|---|

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

high response 2. high precise 3. oil saving 4. water saving 5. long working life

- Q: What's the neutron in the injection machine?

- Is mainly for some relatively special mold design, for example, water pipe three, and the product is also used with screw cutter teeth, these products can not be completely out of the top.

- Q: How to debug the injection molding machine? solve

- You ask too many questions, and debugging involves so many things. If you mean that a process problem is not clear, or you can do other debugging on the injection machine, you can write it out. Plastic injection is not difficult. As long as you are willing to learn, you will not succeed if you depend on it

- Q: Universal charger, product weight 28 grams / sets, mold two (surface shell, bottom shell), one out of eight, material: 7000 yuan / ton, to two 180T injection molding machine production. Since I have just entered the line, how much money can you ask me to do? In this small woman to give you a thank

- The new machine needs 300000 powder machine, 4000 or so change the triangle of the mould, the Longmen frame is several thousand, the cooling water channel, the water pump is several thousand, the cable is several thousandFor three-phase power goes 349Annual tax paymentThe minimum wage is at least three months at least for 12500/ monthsRent a plant for fifty thousand or sixty thousand a yearThe material charge depends on how much you receive and when you collect itYou may have considered buying an old machine, but if you have a large quantity, the old machine is easy to go wrong, and the quantity is less. It's more cost-effective to find someone else to process itAdd a plus, look at the small amount, it is best to find someone to process

- Q: How to reset the EM-120 origin of the injection machine?

- Setting method:1, the high pressure die termination position is set to 0 P2, mold opening to the end;3, press cancel + high voltage lock mode, 3 seconds appear origin setting screen;4, enter 9999 at the preset mode 1; move the cursor back to the preset 1; enter a question mark by the input; Press confirm again;5, press the button manually. Ejection of products; about 10MM after mold adjustment;

- Q: How can the injection machine be set with parameters?

- This problem is too big, ha haSpecific analysis of specific issues

- Q: Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- 168 tons, theoretical injection weight: A--335 grams, B--378 grams

- Q: What are the types of injection molding machines?

- The injection machine is classified according to the following ways:1. classify the raw materials by plasticization and injection.2., according to the injection machine configuration, different classification.3. classification according to the processing capacity of injection molding machine.4. according to the special use of the injection machine classification.

- Q: Seek advice! Is there a better low-pressure injection molding machine? After the sale well, which friends can introduce, thank you!

- As far as I know, the low pressure injection molding machine produced by Connie Technology Co., Ltd. is especially good and provides full range of technical support, which is rich in New Technology

- Q: Renovation and maintenance treasure source injection molding machine, material, pipe, screw, how much money?

- Treasure how many tons of tonnage, small tonnage, there is no need to renovation, and not cost-effective, the source of treasure machine cylinder, some have in stock

- Q: Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.2. vertical machine has the advantages of small footprint, relatively low prices, shortcomings, such as high gravity, inconvenient to take parts, etc., suitable for small molds.

Send your message to us

Injection Molding Machine LOG-500A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords