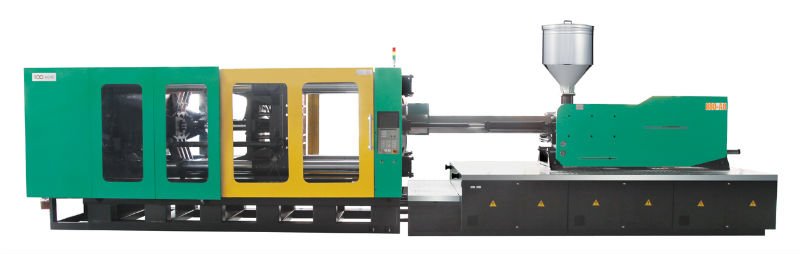

LOG-880A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Shoulder Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG-880A8

Plastic Type: Thermosetting

Automatic: Yes

Injection Weight: 3571g

Injection Rate: 666cm3/s

Clamping Force: 8800KN

Opening Stroke: 1050mm

Packaging & Delivery

| Packaging Details: | one machine in two 40GP containers |

|---|---|

| Delivery Detail: | A week if it's at stock OR a month |

Specifications

high response 2. high precise 3.oil saving 4. water saving 16 long warking life

Details :

| LOG-880A8 | |||||

| International size rating | 7038/880 | ||||

| INJECTION | A | B | C | D | |

| Shot volume | cm3 | 3179 | 3825 | 4750 | 5652 |

| Shot weight | G | 2893 | 3571 | 4321 | 5143 |

| OZ | 102.5 | 126.5 | 153 | 182.1 | |

| Screw diameter | mm | 90 | 100 | 110 | 120 |

| Injection pressure | mpa | 227 | 184 | 152 | 128 |

| Screw L:D ration | 22:01 | 22:01 | 20:01 | 18.3:1 | |

| Screw stroke | mm | 500 | |||

| Screw speed(stepless) | r/min | 0-120 | |||

| CLAMPING UNIT | |||||

| Clamping force | kn | 8800 | |||

| Opening stroke | mm | 1050 | |||

| Platen size | mm×mm | 1530×1530 | |||

| Space between fie bars | mm×mm | 1080×1030 | |||

| Mold fhickness(Min-Max) | mm | 400-1100 | |||

| Max.daylingt | mm | 2150 | |||

| Hydraulic ejection stroke | mm | 300 | |||

| Hydraulic ejection force | kn | 270 | |||

| POWER UNIT | |||||

| Hydraulic system pressure | mpa | 17.5 | |||

| Pump motor | kw | 37+37 | |||

| Heating capacity | kw | 58.45 | |||

| Number of femp confrol zones | \ | 6+ nozzle | |||

| GENERRL | |||||

| Dry-cycle fime | Sec | 8 | |||

| Oil fank capacify | λ | 1900 | |||

| Machine dimensions | m×m×m | 11 X 2.4 X 3.1 | |||

| Machine weight | kg | 48000 | |||

1.template structure of the high-rigidity design,with a bigger clamiping unit. 2. T- slots and conventional screw holes make mold is easy to install. 3 by using our patent bridge structure ,the injection unit will be more stable 4, equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water 5. high-efficiency filter makes the hydraulic oil clean and a long working life 6. the color screen control system, is conventional to operate it.

Products performance and advantages;

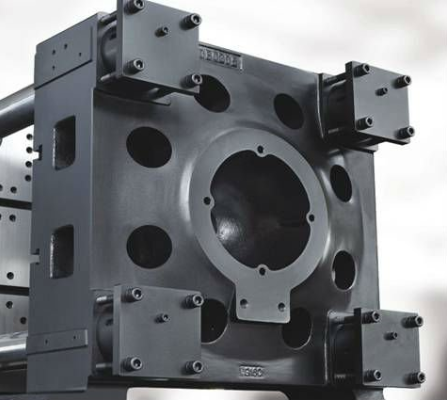

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

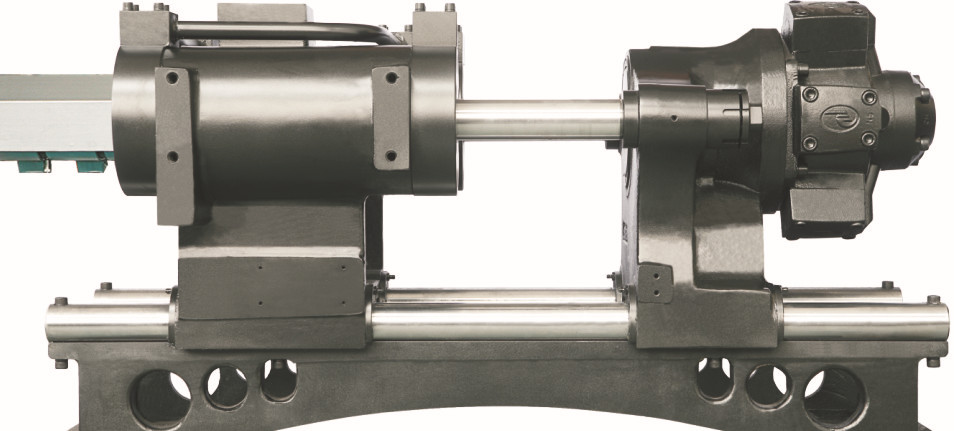

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

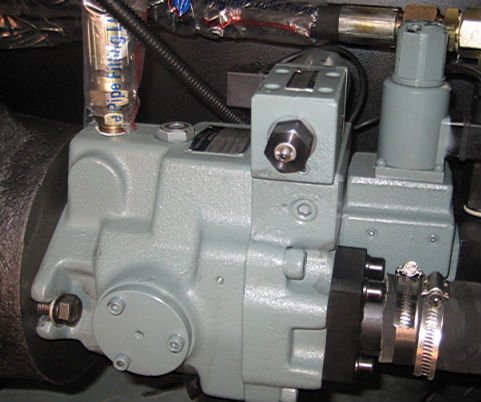

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

- Q: What is an injection molding machine?

- A machine for making plastic products that melts the plastic material and melts it into the mold until the plastic in the mold cools out and is made of plastic.

- Q: Which country was the injection machine invented in?

- In 1958, the first injection molding machine was born in Shanghai, and opened a new page of our own plastic machinery. But the injection molding machine produced at that time was of low technical content, and could only use general plastic to produce daily necessities with lower technical requirements, such as plastic boxes, plastic barrels, plastic basins, etc.. With the development of petrochemical industry in China, China's plastics machinery industry has gradually formed an independent industrial sector, and a certain scale, is an important part of the national machinery industry, especially since the reform and opening up, China's plastics machinery industry has been considerable development.

- Q: injection molding machine is used, every day is 20000G 10000G 7000G of 6000G 4000G 2000G 1000G 560G 210G why the type of injection machine to overcome the number of markers. For example, 20000G injection molding machine can be injected products of the quality of the largest and minimum number of kilograms, thank you

- Injection molding machine models are generally defined in two ways: first, the injection volume (grams); two, clamping force.

- Q: Injection molding machine melt when the screw speed is particularly slow, what is the reason for the oil pound pressure is small?

- 1 temperature is too low,2 pressure and speed is too small3 back pressure is too big4. if other movements are slow, there is a problem with the pressure and speed valve.

- Q: For example, for nylon 6 GF30 material, some injection process information required to set the injection pressure is: 85-100MPa, the actual adjustment of the machine in our injection molding machine panel set the injection pressure is 65, then this number "65" unit is what?If the number of units is "bar", not with the data of some books conflict, please expert answer

- 1MPa=10bar 10KN=1T here are not in conflict, in the injection molding machine test machine computer interface on the back of the unit is 65 bar, we usually say the clamping force is in tonnes, in fact, you can buy some books to look at the injection molding process, more contact with nature will be very clear.

- Q: In the plastic injection molding machine barrel, why there are so many bubbles?

- Is the baked material suitable?.Back pressure is not appropriate?.

- Q: General injection molding machine agents need what conditions?

- DKM injection molding machine agent basic requirements: with injection molding machine sales experience, and has a certain after-sales maintenance capabilities

- Q: From left to right nozzle middle feeding end. Someone told me that the temperature setting should high temperature to low temperature, such as from the nozzle 230220210200. Start is not so ah. Who knows what "nylon 6" as an example to say thank you.

- But if the injection amount is far lower than the theoretical amount of about 80%, due to the homogeneous material is very small, so reduce the temperature to prevent the material plastication decomposition was from low to high temperature Nylon 6 crystal plastic. Its heating temperature starts at the feed port. 240~260270~290 270~280280~290. The machine also varies. I hope it can help you

- Q: Large injection molding machine to block reuse

- First you have to put the head while hot into slices,

Send your message to us

LOG-880A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords