Iinjection Molding Machine LOG-210A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG210-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 347-520 g

Clamping Force: 2100 kn

Opening Stroke: 480mm

Power(W): 18.5 KW

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Screw Diameter: 45-50-55 mm

Injection pressure: 145-217 mpa

Function: Plastic Injection Molding Machinery

Space between Tie Bar: 510*510mm

Material: Stainless Steel

Product Type: PP PE PVC ABS

Warranty: One Year

Packaging & Delivery

| Packaging Details: | Packaging Details: 20 GPcabinet Delivery Detail: In one week after get payment |

|---|

| Description | Unit | LOG-210A8 | ||

| international recognized models | 830/210 | |||

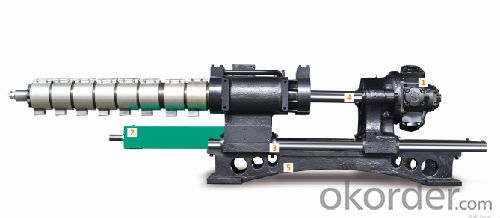

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 381 | 470 | 569 |

| Shot volume | g | 347 | 429 | 520 |

| Oz | 12.1 | 15 | 18.1 | |

| Screw diameter | mm | 445 | 50 | 55 |

| Injection diameter | mpa | 217 | 176 | 145 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| Scerw steoke | mm | 240 | ||

| Screw rotate speed | r/min | 0-200 | ||

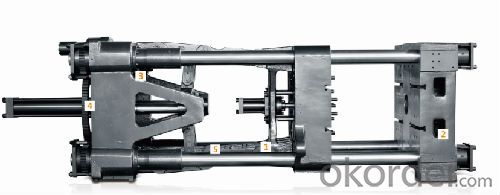

| CLAMPING UNIT | ||||

| Clamping force | kN | 2100 | ||

| Opening stroke | mm | 480 | ||

| Platen size | mm*mm | 745*745 | ||

| Space between tie bars | mm*mm | 510*510 | ||

| Maldthickness | mm | 200-550 | ||

| Platen Mix stroke | mm | 1030 | ||

| Ejection stroke | mm | 150 | ||

| Ejcetion force | kN | 67 | ||

| Power/Elcetric Heating | ||||

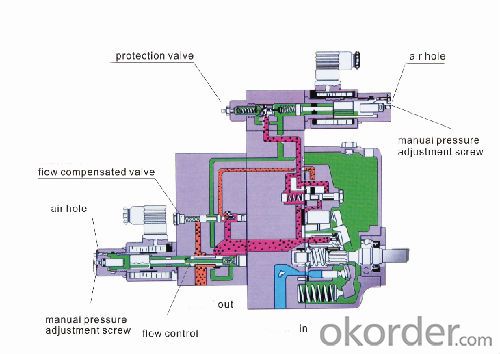

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7 | ||

| Heating power | kw | 13.1 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 4.5 | ||

| Tank volume | L | 310 | ||

| Machine dimesions | m*m*m | 5.4*1.32*2.1 | ||

| Weight of machine | kg | 6800 | ||

- Q: Automation has to be done at the present time when labor costs are going up sharply,

- Secondly, the performance and ease of use of the robot are evaluated. The performance of the manipulator is usually represented by its velocity and precision, speed and high speed reflected in the rapid response, the need of the implementation of components was studied, especially the cylinder and solenoid valve selection determines the performance. The repeatability is mainly reflected by the machining and assembly accuracy of the mechanical components of the manipulator.

- Q: How to change the suction filter core of injection molding machine?

- This is simple,The first ready to stop operation of filter, filter box machine behind the clockwise turn can be replaced, not what skills

- Q: How many moulds can the 80 ton injection molding machine put down?

- There are two main decisions: meaning opening distance, and two is the distance between the guide pillars.

- Q: I want to produce products with high precision, customers reflect the products do not need to buy more stable, precision injection molding machine, injection molding machine is now used in the production of Haitian sword, how to judge the accuracy of horizontal injection molding machine production? What are the indicators to see?

- The product size is usually controlled by injection pressure / pressure, injection volume, holding pressure / time. The selection of injection molding machine mainly depends on the control of the main parameters of "pressure, speed and temperature".In addition, the product size instability, not only related to equipment, and mold injection molding technology also has a lot to do with parts and materials also related, you should analyze the reasons in many ways.

- Q: Quanlifa injection molding machine can replace the barrel and screw size

- Screw barrel size can change, but can not change too much, too big to carry motor and screw will not rotate, change is too small, you have to look at the ratio of length to diameter, ratio of length to diameter is too large, easily broken screw.

- Q: How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

- Q: My company bought several days to fully send the injection molding machine! Secondhand! What seems to be a small barrel?! 600t's injection molding machine seems to be about the same size as the Haitian 160t in our factory! But the motors are big! 600t motors have 77kw! What's more, there are two cylinders in the part of the machine that I don't know what to use!!Don't look for the production of daily necessities but also bought no way only to re make a barrel of the two cylinders is said to have a small pump oil to two cylinders to increase the pressure to speed up not by nitrogen small motor without the proportional valve directly into the cylinder direct injection to do it ordinary machine line

- The high speed cylinder, speed faster than the general machine, the injection quantity is smaller. To be fast, the motor power is certainly a bit bigger. You still have a small, 600 tons of new models, the power of the motor is greater. The two cylinders are nitrogen cylinders for increasing speed.It's kind of a different kind of machine, and I don't know if it will work for you.

- Q: What does the injection machine do?

- [injection molding machine] also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.The injection molding machine has the ability of a complex shape, size precision or with plastic metal inserts texture dense, is widely used in national defense, electronics, automotive, transportation, building materials, packaging, agriculture, education, health and daily life in various fields. In today's rapid development of plastic industry, plastic injection molding machine plays an important role both in quantity or variety, the total production of the plastic molding equipment 20%--30%, thus becoming the fastest growth in plastics machinery, one of the largest number of production model.

- Q: Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.

- Q: Novice ask: can rubber injection molding, plastic injection function?

- Rubber can be injection molded and has a special rubber injection molding machine (plastic requirements for blended rubber). Plastic injection molding machine can not be used for rubber injection molding.

Send your message to us

Iinjection Molding Machine LOG-210A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords