injection molding machine LOG-160S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Other | Style: | Horizontal |

| Brand Name: | LOG machine | Model Number: | log-160s8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 260-368g |

| Injection Rate: | 122-172g/s>122-172g/s |

| Clamping Force: | 1600kn | Opening Stroke: | 430mm | ||

| Power(W): | 27.6kw | Certification: | CE ISO9001 | After-sales Service Provided: | Engineers available to service machinery overseas |

| Color: | design by onself |

Packaging & Delivery

| Packaging Details: | 20GP |

Product Description

LOG-160S8 SPECIFICATION

International size rating 525/160

INJECTION A B C

Shot volume cm3 277 318 392

Shot weight G 260 298 368

OZ 9.1 10.5 12.9

Screw diameter mm 42 45 50

Injection pressure mpa 190 166 135

Screw L:D ration 20:1 20:1 18:1

Screw stroke mm 200

Screw speed(stepless) r/min 0-200

CLAMPING UNIT

Clamping force kn 1600

Opening stroke mm 430

Platen size mm×mm 680×680

Space between fie bars mm×mm 460×460

Mold fhickness(Min-Max) mm 180-500

Max.daylingt mm 930

Hydraulic ejection stroke mm 140

Hydraulic ejection force kn 50

POWER UNIT

Hydraulic system pressure mpa 17.5

Max.motor current A 64

Heating capacity kw 12.6

Number of femp confrol zones \ 4+ nozzle

GENERRL

Dry-cycle fime Sec 2.0

Oil fank capacify λ 210

Machine dimensions m×m×m 4.95×1.25×2.0

Machine weight kg 5300

Certifications

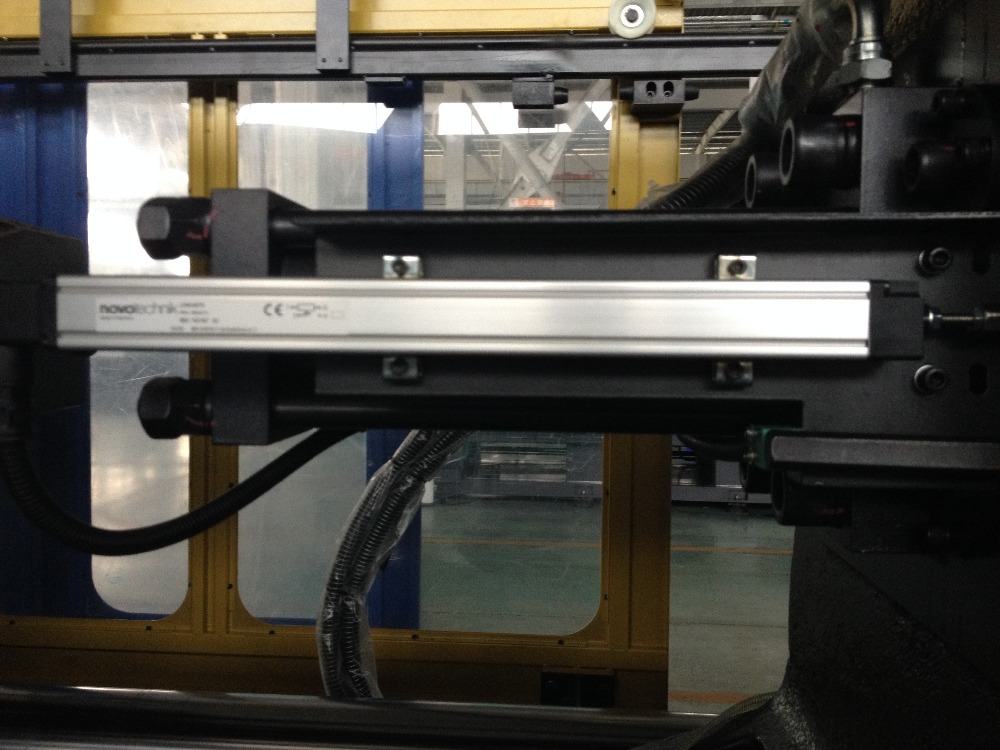

Detailed Images

Pre-Sales Service

Packing & Delivery

Packaging | |

Size | 4.95(M) * 1.25 (M) * 2.0 (M) |

Weight | 4720KG |

Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

- Q: How about overheating of injection molding machine drives?

- Ask for advice! The factory has the secret MA1600 of the Taiwan Strait, the drive is over temperature, the electric heating is not hot, the motor contactor does not suck

- Q: List of injection molding machines

- Demag DEMAG Austria: Japan ENGEL brand: Toshiba TOSHIBA, Japan TOYO, MITSUBISHI MITSUBISHI, Sumitomo SEDU, FANUC FANUC method, Niigata NIIGATA,

- Q: how fast preheating ah, the more detailed the better, do not understand, please do not answer, online, etc.

- Brother, brother, I've just solved the problem. It's too easy... There is a temperature sensing line in the tank. Pull it out. Use a small bottle (put some warm water, not too hot, or higher temperature)... That's it.

- Q: What is the gear adjustment and chain adjustment of the injection molding machine?

- The chain adjustment is to adjust a motor to drive a chain, and then drive a few small gear.

- Q: What kinds of oil are used in the injection molding machine?

- 46# or 68# anti-wear hydraulic oilIn summer, use 68# anti-wear hydraulic fluid, 46# or 68# anti-wear hydraulic fluid.Domestic, the Great Wall, Kunlun will do is false too much, how long to change oil ah, lock cylinder with sub fuel tank, injection molding machine industry should use the most "run times", escape the oil in the air,. There are stamping, injection molding done, very few false.

- Q: How much is the ejection rate of injection molding machine?

- Generally transferred to 4, to 6 can be, I hope my answer will help you - Switek

- Q: We are going to an injection molding machine factory at once. I don't know yet which is what I learn, NC, please master, and hope to be able to put the knowledge about injection molding machine told me, I appreciate the injection molding machine is that NC programming ah | please master, thank you

- Injection molding machine can not be programmed, mainly the use of operations, adjustment, parameter settings, etc.

- Q: The products produced by injection molding machines include flying edge, burn and burn

- As for what you are talking about, guess you've just learned how to adjust the machine. These problems can only be produced in the new test die, and the mold will be carbonized because of the foreign matter in the cavity...... There is a problem in communication, to rest.

- Q: For example, according to the shape, the injection quantity, clamping force, and electric, all electric ^^^ hope to get a more comprehensive answer Thank you!!!

- As the structure and types of injection molding products are relatively large, the injection molding machine used for molding injection products is also more. The injection machine is classified according to the following ways:1. classify the raw materials by plasticization and injection.2., according to the injection machine configuration, different classification.3. classification according to the processing capacity of injection molding machine.4. according to the special use of the injection machine classification.According to the classification of raw materials plasticizing and injection methods, the injection machine can be divided into: (1) plunger type, (2) reciprocating screw type and (3) screw, plasticizing plunger, injection type three.According to the structure of the injection machine, it can be divided into: (1) vertical injection molding machine, (2) horizontal injection machine, (3) angle injection machine, (4) multimode injection machine, (5) combined injection machine.According to the size of the processing capacity to the injection machine classification, can be divided into: (1) ultra small injection machine, (2) small injection molding machine, (3) medium-sized injection molding machine, (4) large injection machine (5) super large injection molding machine.By use of the injection machine can be divided into: (1) general injection machine, injection machine exhaust (2), (3) high speed precision injection machine, injection machine (4), (5) three plastic shoes injection head single mold injection machine, double head two (6) injection mould injection molding machine.

- Q: What is I/O on an injection molding machine?

- I means "IN", and "O" means "OUT.", that is "input" and "output"

Send your message to us

injection molding machine LOG-160S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords