injection molding machine LOG-130S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG 130S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 239 |

| Clamping Force: | 1300kn | Opening Stroke: | 380mm | Power(W): | 12kw |

| Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 Days |

Product performance and advantages:

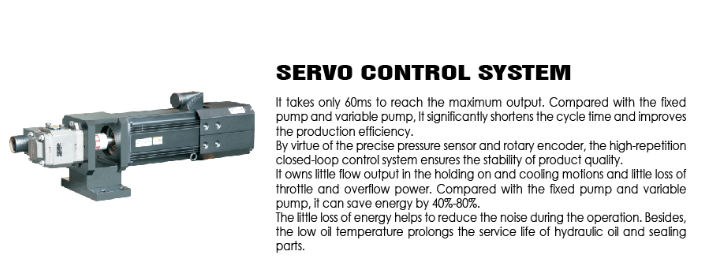

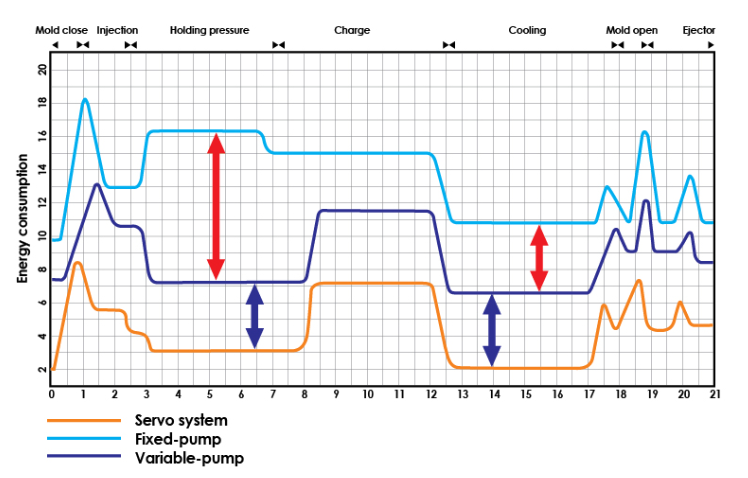

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in

comparison with conventional hydraulic injection molding machines. The response speed has been obviously

increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-130S8 Technical parameters

Description | Unit | LOG-130S8 | ||

international recognized models | 416/130 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 215 | 263 | 302 |

Shot volume | g | 196 | 239 | 274 |

Oz | 6.9 | 8.4 | 9.6 | |

Screw diameter | mm | 38 | 42 | 45 |

Injection diameter | mpa | 193 | 158 | 138 |

Screw L:D ratio | 22:1 | 20:1 | 18:1 | |

Scerw steoke | mm | 190 | ||

Screw rotate speed | r/min | 180 | ||

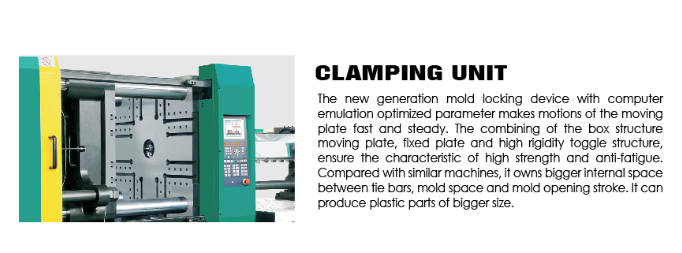

CLAMPING UNIT | ||||

Clamping force | kN | 1300 | ||

Opening stroke | mm | 380 | ||

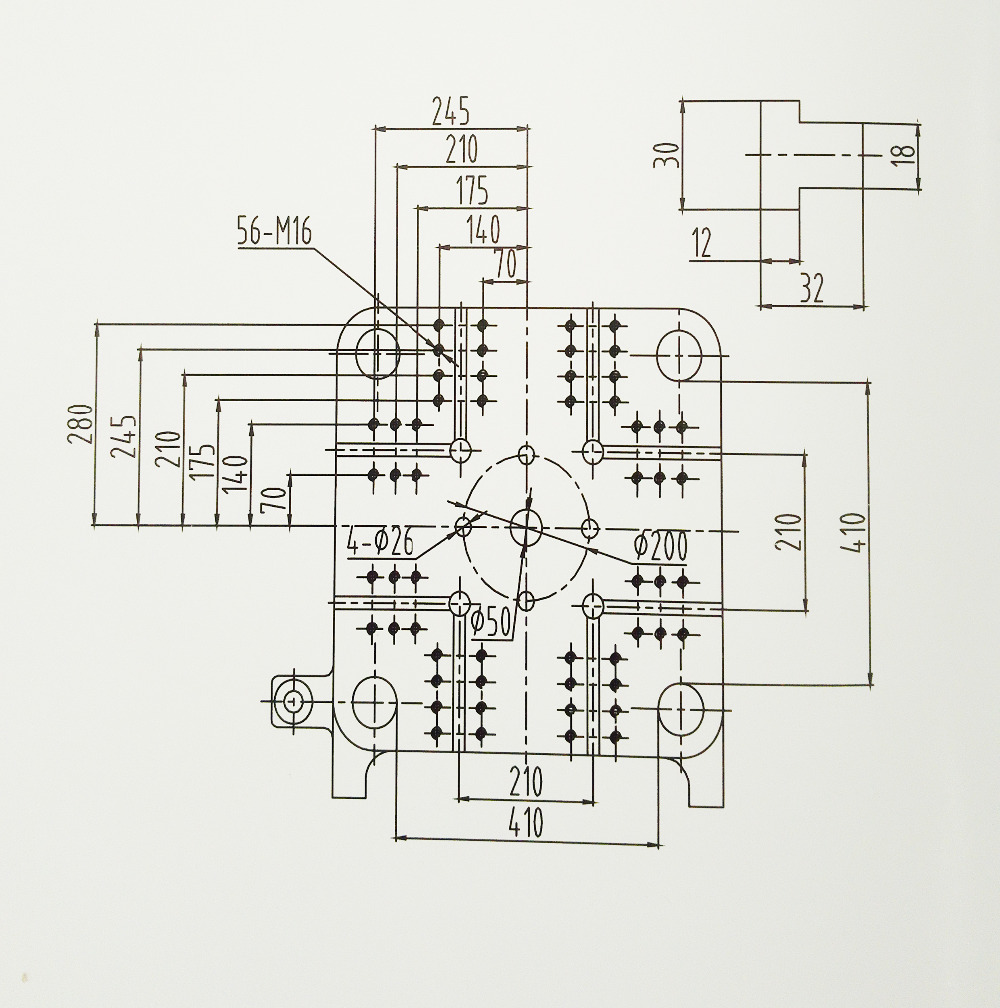

Platen size | mm*mm | 610*610 | ||

Space between tie bars | mm*mm | 410*410 | ||

Maldthickness | mm | 150-430 | ||

Platen Mix stroke | mm | 810 | ||

Ejection stroke | mm | 120 | ||

Ejcetion force | kN | 42 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 12 | ||

Heating power | kw | 7.7 | ||

Number of temp.conteol | 4+nozzle | |||

Other | ||||

Cycle time | sec | 1.3 | ||

Tank volume | L | 200 | ||

Machine dimesions | m*m*m | 4.6*1.2*1.8 | ||

Weight of machine | kg | 4000 | ||

Platen Dimensions:

product

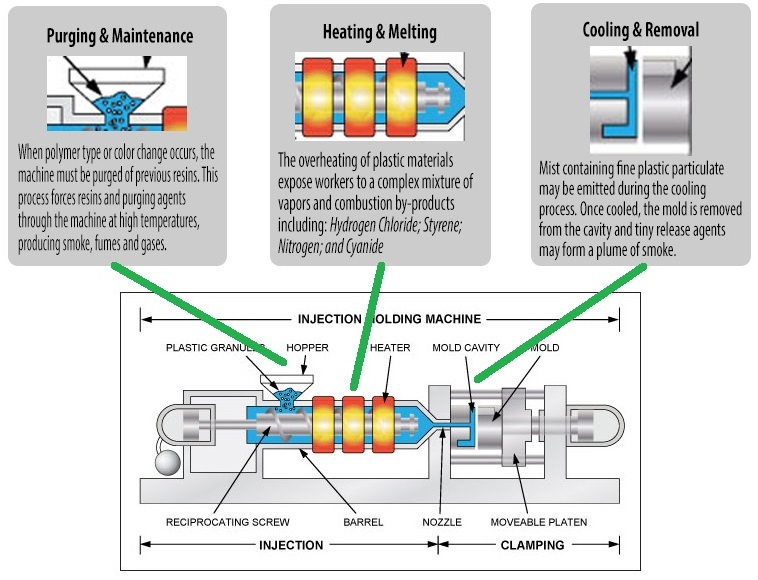

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q: Injection molding machine, blister machine, blow molding machine, what is the fundamental difference?

- Injection molding machine - a machine that produces plastic products by filling the mold with pressure.

- Q: Renovation and maintenance treasure source injection molding machine material pipe screw how much?

- This simple to: remove the barrel wall need to stick with the smooth talking drum material original material rod slightly special barrel trim surface treatment like new repair gas cylinder can influence

- Q: How will the screw speed of injection molding machine be adjusted slowly?

- 1) the rated screw speed of injection molding machine. When molding PS, the plasticizing capacity and the screw speed of the material to be processed are calibrated by 50%--60% of the rated plasticizing quantity.2) determine the screw speed according to the maximum linear speed that the polymer can allow.The maximum speed of screw is n=V/ PI DThe maximum line speed allowed by V---- polymers in the formula. General polymer V=80cmm/S thermosensitive polymer V=1.8cm/sD---- screw diameter (CM)3) depending on the allowable shear rate r of the polymer, the V in the upper form is replaced by R and then determined.

- Q: How do you increase your product? How do you assign multiple segments? Speed? How to determine the holding position? Big, good or small? All help answer! Be deeply grateful!

- The size of each of the products are different in nature, the machine method is not the same, increase the product I will generally use four, the first section of second section is walking the gate, go to watch it go gum products, is to prevent it, trapped gas or gas lines, third pressure faster than second some a little slower, the vantage point to almost full gum, last paragraph third paragraph is used as an outlet, the rate dropped to 10 or 15, the pressure to about 65, he shot to see which position began to pressure the pressure point is set to fourth position, if the material is difficult to shrink a good tune, put on three to Paul has shrunk, such as the first stage pressure 10, speed 15, 0.5 seconds, second pressure 20, speed 25, a second time, third pressure of at least 130 or more, the speed of not more than 45, at least 4 seconds If not, cut the amount of the first and second periods to control shrinkage. Of course there are sure to barrel temperature, mold temperature, get well, water or oil are related to important. I can answer that for you so far. Honestly, I've only been studying for 9 months so far. I've got everything to learn there. In fact, I want to be familiar with this line and practice more

- Q: What measures can be taken to shorten the molding process cycle of injection molding machines?

- Reduce the mold temperature, reduce the heating temperature of cylinder, increase the speed of die closing and shorten the cooling and holding time.

- Q: Universal charger, product weight 28 grams / sets, mold two (surface shell, bottom shell), one out of eight, material: 7000 yuan / ton, to two 180T injection molding machine production. Since I have just entered the line, how much money can you ask me to do? In this small woman to give you a thank

- The new machine needs 300000 powder machine, 4000 or so change the triangle of the mould, the Longmen frame is several thousand, the cooling water channel, the water pump is several thousand, the cable is several thousandFor three-phase power goes 349Annual tax paymentThe minimum wage is at least three months at least for 12500/ monthsRent a plant for fifty thousand or sixty thousand a yearThe material charge depends on how much you receive and when you collect itYou may have considered buying an old machine, but if you have a large quantity, the old machine is easy to go wrong, and the quantity is less. It's more cost-effective to find someone else to process itAdd a plus, look at the small amount, it is best to find someone to process

- Q: How many moulds can the 80 ton injection molding machine put down?

- The machines of each brand are slightly different. The width is usually 350.

- Q: when the temperature rising in the exit but this is what the normal temperature increase of more than 20 degrees

- 1, your machine back pressure regulation is too large; 2, screw idle or slip, cause melt time longer, friction produce heat; 3, setting temperature is too low, melt resistance is too large, friction produce heat;

- Q: Excuse me: what are the differences between injection molding and extrusion?

- The following answer is very good, I'm adding. 1, injection = injection molding machine + injection mold; extrusion = extrusion + mouth mold, core mold + cooling trough. Among them, the injection molding machine and extruder, almost all of the plastic melt. The difference is in the mold: injection mold, there is the upper and lower mold, together, inside the processing cavity, and that is the same shape as the product. The plastic particles melt into the closed mold cavity, cool down, open the mold and take out the product.

- Q: How can I adjust the mold automatically when there is foreign matter in the mold? How about the location of the front and rear die blocks?. Be detailed and simple

- 1, low pressure clamping point, and even can go to zero,2, the speed is slow, as long as the mold in the fast mode locking inertia, continue to move on3, low voltage protection time is short.That is to say, the clamping force in the process of low voltage die clamping is smaller, the speed is slow, and the time of low voltage protection is short. Can play the role of low voltage protection, in the mold when there is foreign body, timely response, automatic mold opening.Set the position according to the actual situation of the mold.

Send your message to us

injection molding machine LOG-130S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords