LOG-1080A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Condition: New | Place of Origin: China (Mainland) |

| Type: Tube Head Injection | Plastic Type: Thermosetting |

| Style: Horizontal | Automatic: Yes |

| Brand Name: LOG | Injection Weight: 4540g |

| Model Number: LOG-1080A8 | Injection Rate: 21250px3/s |

| Opening Stroke: 1150mm | Clamping Force: 1080KN |

| Energy saving |

Packaging & Delivery

| Packaging Details: | the LOG-1080 will be shipped by 40'HP container,because of the weight and size |

|---|---|

| Delivery Detail: | 7 days after receive the diposit OR month |

Specifications

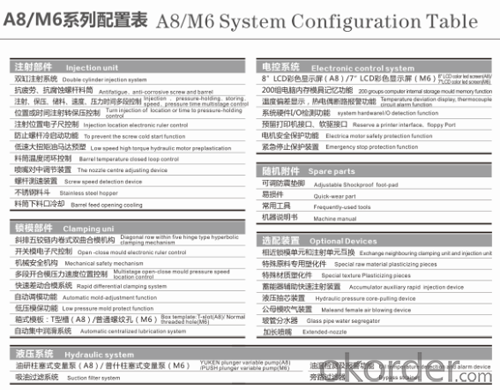

1.high response 2. high precise 3. oil saving 4. water saving 5. long warking life

Details

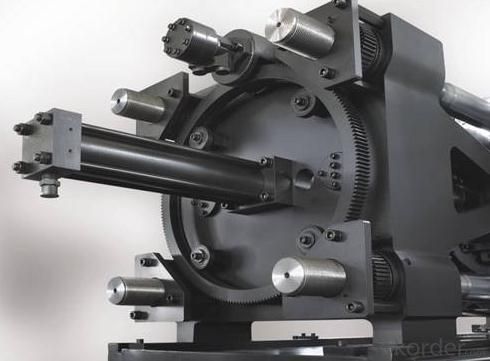

template structure of the high-rigidity design,with a bigger clamiping unit.

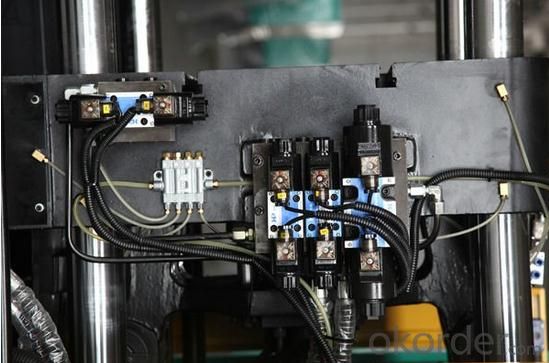

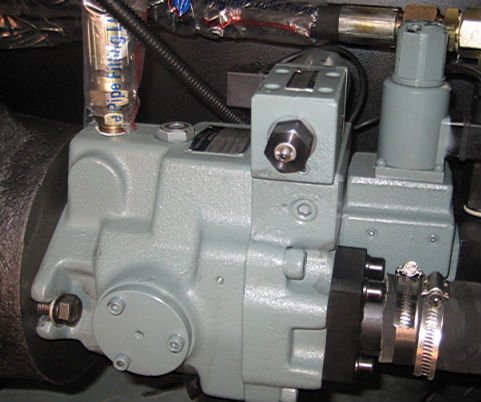

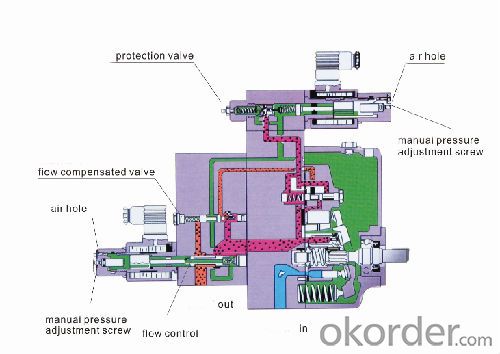

equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water

high-efficiency filter makes the hydraulic oil clean and a long working life

the color screen control system, is conventional to operate it.

T- slots and conventional screw holes make mold is easy to install.

| LOG-1080A8 | |||||

| International size rating | 9080/1080 | ||||

| INJECTION | A | B | C | D | |

| Shot volume | cm3 | 4123 | 4989 | 5938 | 6968 |

| Shot weight | G | 3751 | 4540 | 5403 | 6340 |

| OZ | 132.8 | 160.8 | 191.4 | 224.5 | |

| Screw diameter | mm | 100 | 110 | 120 | 130 |

| Injection pressure | mpa | 220 | 182 | 153 | 130 |

| Screw L:D ration | 22:01 | 22:01 | 20:01 | 18.6:1 | |

| Screw stroke | mm | 525 | |||

| Screw speed(stepless) | r/min | 0-110 | |||

| CLAMPING UNIT | |||||

| Clamping force | kn | 10800 | |||

| Opening stroke | mm | 1150 | |||

| Platen size | mm×mm | 1650 X 1650 | |||

| Space between fie bars | mm×mm | 1150 X 1100 | |||

| Mold fhickness(Min-Max) | mm | 450-1200 | |||

| Max.daylingt | mm | 2350 | |||

| Hydraulic ejection stroke | mm | 350 | |||

| Hydraulic ejection force | kn | 270 | |||

| POWER UNIT | |||||

| Hydraulic system pressure | mpa | 17.5 | |||

| Pump motor | kw | 45+45 | |||

| Heating capacity | kw | 68.45 | |||

| Number of femp confrol zones | \ | 6+ nozzle | |||

| GENERRL | |||||

| Dry-cycle fime | Sec | 10 | |||

| Oil fank capacify | λ | 2300 | |||

| Machine dimensions | m×m×m | 12.5X2.8X3.5 | |||

| Machine weight | kg | 60000 | |||

Some details about the machine:

- Q: What are the common problems and solving methods of injection molding machine? The more detailed, the better the month

- Non thimbleA, the actual location of the mold is not up to the actual setting;B, computer set no thimble or thimble times zero;C, the set of process parameters are incorrect;Detection status of D and thimble electronic ruler;Mechanical damage of E and ejector pin mechanism;F, the valve out of the direction of the valve is charged and spool work is normal.No needleA, computer process parameters;Detection status of B and electronic ruler;C, the working state of the directional valve.Abnormal movements of the meltA, the temperature of the melt tube is not set;B, the process parameters are unreasonable;Detection status of C and electronic ruler;D, the working state of the directional valve;E, melt into the cylinder with hard objects, stuck screw;Behind F, the barrel does not lead to water transport water, feeding inlet temperature is too high;G, glue back pressure is too large, check back pressure valve;H, adhesive motor or transmission shaft failure;I, hopper no material;The ejection motion is abnormalDetection status of a and electronic ruler;B, the working state of the directional valve;C, speed, pressure, position and time setting of process parameters;D, melt tube or nozzle temperature is not set;E, foreign body stuck in the melt tube;F, nozzle blocked;The G, the firing point and the stop switch do not work.Semi automatic and fully automatic working state is out of orderThe first observation is the problem in which a working condition, and then checked for specific actions, full automatic working condition but also to check the electric eye or time setting.

- Q: The working principle of injection molding machine

- The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products.Injection molding is a cycle process, each cycle mainly include: quantitative feeding - melt plasticization - pressure, injection - filling mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle.Injection molding machine operation items: injection molding machine operation items, including control keyboard operation, electrical control system operation and hydraulic system operation three aspects. The injection process, feeding action, injection pressure, injection speed, ejection type, temperature monitoring, injection pressure and back pressure adjustment are carried out respectively.The molding process of the general screw injection machine is first granular or powdered plastic into the machine barrel and then through the rotation of the screw and barrel wall heating the plastic as molten state, then the machine mold and the injection seat moves forward, to close the mold gate nozzle, the pressure oil through to the injection cylinder then, the screw to move forward at a high pressure and speed will melt into the closed mold temperature low, after a certain period of time and pressure (also called pressure), cooling, the curing, can remove mold products (pressure to prevent molten material the reflux, supplementary materials, to ensure the products with the mold cavity and the density and size tolerance in a certain cavity).

- Q: Now I know a product of the material cost unit (single weight + nozzle), but how to calculate artificial + factory rent + machine wear + Plus transport + packing material, seek heroes pointing. emergency

- The cost of plastic parts is related to many factors, but mainly with the following points:1. Cost of raw material --- this cost is relatively good calculation, ask a raw material supplier how much 1 kg, the weight of the product multiplied by 3% of the loss multiplied by the raw material price, you can get the cost of raw materials;2.. This machine cost about plastic factory, what is the cost of processing per hour of different injection molding machine? Suppose the 1 ton injection molding machine costs 60 yuan / hour per hour, then the processing cost is 1 yuan per minute. At this time, we should calculate the cost of the 100 ton machineWhat is the injection period of plastic parts and how many opening holes are in the mold? Suppose you want to evaluate the injection period of the plastic partsFor 30 seconds, then 1 minutes can shoot 60 seconds divided by 30 equals two, said 1 minutes can shoot the second mock exam products, in addition to a two point that mold, then plastic machine processing costs 1 yuan by 1 minutes and then divided by the modulus of mouldThe number of holes to get the final machine processing costs, that is, 1 yuan divided by 2 modules, and then divided by 2 points, and finally wait until 0.25 yuan /3., two additional costsThe two processing costs include painting / screen printing / plating etc. These can be referred to their respective processing plants4. packing chargesAccording to the size and volume of the plastic parts, we can draw the packing carton / packing bag and so on;5. transportation costAccording to the location of delivery and how much container freight can be loaded, divided by the total number of trucks to be shipped per PCCost;6. other expenses;Since the above costs do not include the costs of indirect personnel and their associated personnel, there is also a need to add some costs to each plant;

- Q: Quanlifa injection molding machine can replace the barrel and screw size

- Of course, the size range not too big, we do is screw barrel.

- Q: What is the back pressure in the injection molding machine?

- Back pressure: screw back when applied to the rod end of rubber pressure. It can reduce material consumption and bubble phenomenon.A: when the back pressure is adjusted properly, the density of the melt can be increased, the air discharged by the air in the cylinder can be discharged, and the rubber material is compacted, so that the cycle of the beer mould is stable, and the production efficiency is improved.B: back pressure is high, screw speed is slow, the resistance is large, the barrel screw is easily damaged, because the screw friction heat, heat increase in external heating unchanged, will make the temperature rise, the viscosity decreased, resulting in leakage and countercurrent flow, the nozzle is easy to produce salivation phenomenon.C: low back pressure and screw speed is fast, but it is difficult to put the rubber barrel compaction, the particles is not uniform, resulting in flower phenomenon, such as adding toner material will appear in different shades of color.Note: feed back when the screw rotation should be shaped, injection should be straight. 1, can melt inside the barrel compaction, increase density, improve the stability of injection quantity, weight and size of the products.2. The gas in the melt can be extruded to reduce the gas, the inner bubbles and the gloss uniformity of the products. Slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon.3, slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon.4, appropriately increase the back pressure, can improve the product surface shrinkage and product periphery walk glue situation.

- Q: RTBrother recently understand the injection mold related knowledge, about the forming cycle of this problem, I do not know whether this cycle can be estimated according to the relevant parameters, please advise!Forming cycle: the time between the previous product and the next product, including the time taken by the manipulator, and so on. I am for the new quotation, not too precise, but not too far away, trouble expert advice, small first, thank you very much!

- If a trial can be used to test out the stopwatch + wide release time, not the trial production of new software available for calculation, but the structure of a product cycle also depends on the size and thickness of the product, is complex and molding technology to all of these affect the product cycle, your statement is not very clear and it is difficult to give you a more accurate estimate of the cycle, experienced personnel can structure size, thickness, the product was estimated, and more reasonable!

- Q: Commissioning process of injection molding machine

- 3. calculate the relative viscosity of the plastic with the reciprocal of the filling time multiplied by the peak pressure value. The reciprocal of the filling time is the abscissa, the relative viscosity is the ordinate, and the relative viscosity is plotted. The viscosity curve can be found in the low speed high speed changes more, little viscosity change, find a middle viscosity curve trend in value from flat as we used for the production of fire, (also can be judged according to the change of filling time of plastic viscosity stability when the filling time changes, the peak pressure is small) to overcome the rubber mold flow resistance when the pressure, but also beer pieces of the actual pressure, we use this value is greater than 10% for injection pressure.4. determine the pressure and speed, then come to the switching point, do the packing and feeding in beer 95% ~ 99% position switch for holding position. (padding should be controlled by position rather than pressure or time)5. the filling time should be constant, the injection time is longer than the filling time, so as not to be controlled by time, for example, the injection time, whether it is 4 seconds or seconds, the filling time is about 1 second.6. in this way, the filling time and the holding time can be set up. The average injection time is 0.5 seconds longer than the filling time, and the other can be used as the holding and filling time.

- Q: How to choose an injection molding machine

- The selection of injection molding machine is usually made by the following parameters, for reference.1: modulus of capacity, that is, the maximum plastic mold size that can be placed.2: amount of material is melt, maximum amount of glue tube can shoot a glue, injection molding products of the first mock exam should not exceed the total amount of 70% melts.3: clamping force, with reference to the largest product surface area, the maximum injection pressure, the mold can not open the clamping force.

- Q: How does the injection machine set up the die segments and the pressure and speed of each segment? Seek advice.

- The new technology is the use of branch switch reluctance servo motor, motor CNC pump speed control speed, motor CNC pump torque control pressure, through the touch screen input segment parameters, the implementation of numerical control.

- Q: Why should the central feed system be used in the injection molding workshop?

- The advantage of using the central feed system in the injection molding workshop is that:1. save energy2. save labor costs3. improve the company's overall image4. keep the factory environment clean and tidy5., centralized management of raw materials to avoid waste of raw materials and pollution6., can isolate the main transmission, reduce noise pollution"Dongguan niasi" the central feeding system adopts the vacuum conveying mode, through the pipeline system will focus on plastic raw materials from the storage tank is transferred to the central dehumidification system will then transport the raw material after drying to each injection molding machine. "Dongguan niasi" the central feeding system adopts "design a machine of a pipe", to ensure the whole system of raw materials for air transport, to prevent the resurgence of the raw material after drying dehumidifying. At the same time, the pipeline can be cleaned up after each conveying cycle to ensure that there is no residual granular material in the pipeline. The material performance of the injection molding machine is guaranteed to be consistent while avoiding the resurgence of the raw material. Under the vacuum negative pressure, the dust in the raw material will be filtered out through the dust filtration system, which will help to improve the quality of the molding products.Please refer to the resources below for a detailed example of the central feeding system!!!

Send your message to us

LOG-1080A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords