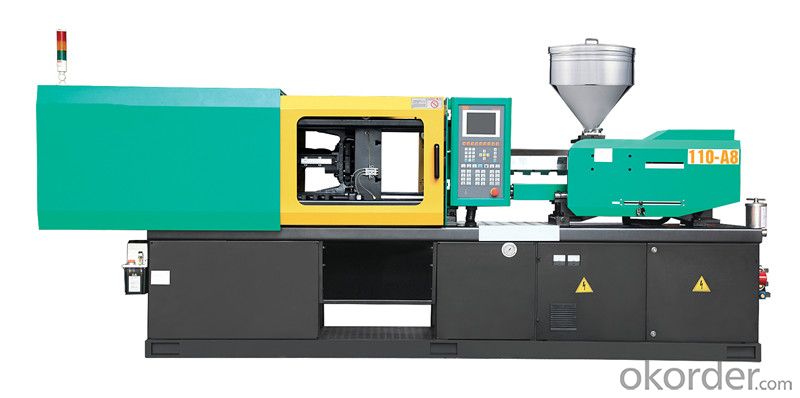

Injection Molding Machine LOG-110A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: 110A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 192

Clamping Force: 1100KN

Opening Stroke: 350mm

Power(W): 11

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

| Description | Unit | LOG-110A8 | ||

| international recognized models | 370/110 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 163 | 192 | 235 |

| Shot volume | g | 148 | 175 | 213 |

| Oz | 5.2 | 6.2 | 7.5 | |

| Screw diameter | mm | 35 | 38 | 42 |

| Injection diameter | mpa | 228 | 193 | 158 |

| Screw L:D ratio | 21.7:1 | 20:01 | 18:01 | |

| Scerw steoke | mm | 170 | ||

| Screw rotate speed | r/min | 0-180 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 1100 | ||

| Opening stroke | mm | 350 | ||

| Platen size | mm*mm | 600*550 | ||

| Space between tie bars | mm*mm | 405*370 | ||

| Maldthickness | mm | 150*380 | ||

| Platen Mix stroke | mm | 730 | ||

| Ejection stroke | mm | 100 | ||

| Ejcetion force | kN | 42 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 12 | ||

| Heating power | kw | 7.5 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 1.3 | ||

| Tank volume | L | 200 | ||

| Machine dimesions | m*m*m | 4.3*1.2*1.8 | ||

| Weight of machine | kg | 3600 | ||

Products performance and advantages;

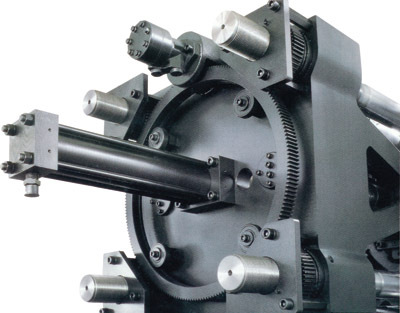

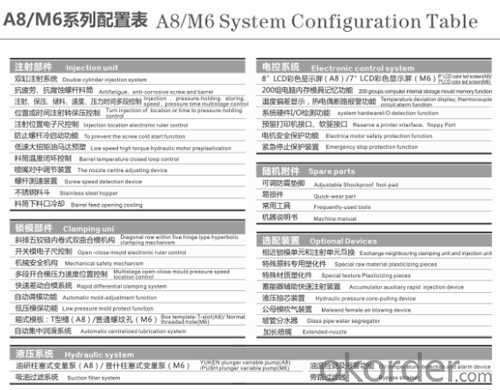

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

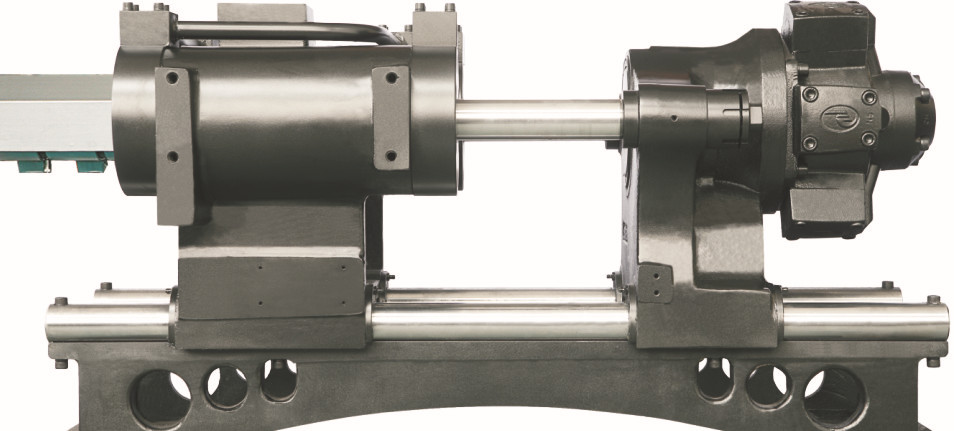

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

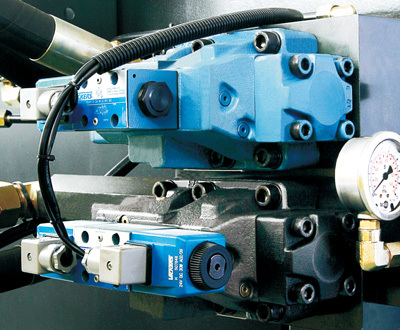

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

- Q: How about overheating of injection molding machine drives?

- Flow control principle of injection molding machine drive:When the pressure sensor detects that the pressure is less than the pressure setting value, the servo drives the servo motor to control the rotational speed so that the output flow of the pump is kept at the set point.Principle of pressure control for injection molding machine drive:When the pressure detected by the pressure sensor reaches a set value, the servo driver controls the torque of the servo motor so that the output pressure of the pump is kept at the set point.

- Q: Injection molding machine melt when the screw speed is particularly slow, what is the reason for the oil pound pressure is small?

- 1, screw to see the size of the pressure gauge, such as large back pressure is too high or low temperature2, still bad, sol valve stuck, 3MM poke the valve core or remove the cleaning3, to see the small gauge storage speed, low pressure, low system parameter setting4, other movements, if the pressure is small, it is possible when the pressure of the oil pump is small

- Q: What an elder brother knows how nitrogen injection is going on. What should I pay attention to?

- 1. the operator must undergo good safety education.2. operate strictly according to the operating rules of equipment.3., when the valve operation, wear protective equipment: masks, gloves, etc., to prevent frostbite.4. check the safety valve and pressure gauge once a year, check the riot film every two years, check and record the records.5. when the nitrogen emissions, people should stay away from the drain, otherwise, long time suffocate easily.6. in the obvious place to hang around the nitrogen tank "trespassers", "dangerous" and other warning signs.7. freezing on nitrogen pipe, no heavy blow.8. check the nitrogen tank every day and find the problem in time.9. always keep the nitrogen tank clean and free of oil and grease.10. equipment should be cut off for a long time without gas.

- Q: What should be noticed before the machine is stopped when the injection machine is finished?

- Dongguan City Zhen Ying Machinery equipment limited company to remind you: to prolong the life of the injection molding machine, usually must take good care of!

- Q: What plastic injection machines and materials are needed for making plastic waste shovels?

- Should use horizontal injection molding machineThere are several kinds. Pc.pom.pp.pa66+30%, see how you choose it.

- Q: when the material stored, the screw has been in situ, and will not go back to the set stop position. What shall I do?

- When the material storage, you look at the nozzle has no material, if there is no transfer under the pressure, if you look at the material hopper have feed tube material, if there are very thick material in the hopper below the card down to the tube without glue, will have to screw in the back. Not always

- Q: What's the pressure and speed of melt press in injection molding machine?

- Sol pressure: commonly known as back pressure, refers to the back of the screw when the pressure carried. Sol speed: injection molding machine in the gum into the screw drive, the screw moving speed, that is, the plastic into the screw speed.The new technology adopts the switched reluctance servo motor to drive the hydraulic pump and drive screw to realize the valveless servo hydraulic system with high efficiency and energy saving and high reliability.

- Q: Injection molding machine maintenance Daquan books catalog

- The eighth chapter is about the operation and adjustment of common injection molding machineSection 1 operation panelI. computer operation panel of injection molding machineTwo, Jin PT-160 operating panelThree, Haide HDB-120 operation panelOperation and adjustment of injection molding machine in second sectionsFirst, shock male, Czech tyrants, C series of energy-saving injection molding machineTwo, Jin PT series injection molding machineThree, Hai Debao HDB series injection molding machine

- Q: The products produced by injection molding machines include flying edge, burn and burn

- As for what you are talking about, guess you've just learned how to adjust the machine. These problems can only be produced in the new test die, and the mold will be carbonized because of the foreign matter in the cavity...... There is a problem in communication, to rest.

- Q: Debugging and debugging process of injection molding machine

- (2) products shrinkFault reason handling methodInsufficient mold penetrationThe amount of melt is not enough, plus the amount of melt adhesiveLow glue pressure, low pressureHigh back pressure back pressure is not enoughInjection time too short injection timeInjection speed is too slow or fastThe overflow is uneven and the overflow of the mold is too small or in placeThe nozzle hole is too thin, plastic in the sprue bushing in solidification, reduce the back pressure effect. Adjust the mold or replace the nozzleMaterial temperature is too high and material temperature is lowImproper temperature and proper temperatureThe cooling time is not enough to prolong the cooling timeWhen the pressure storage section is too large, the adhesive shall terminate at the front endThe product itself or its ribs and columns are too thick to review the finished product designExcessive injection of glue to replace the finer injection molding machineWear removal of apron and adhesive screwGate is too small, plastic solidification loss, back pressure action, increase gate size

Send your message to us

Injection Molding Machine LOG-110A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords