Injection Molding Machine LOG-400A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG-400A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 1646g

Injection Rate: 406cm3/s

Clamping Force: 4000KN

Opening Stroke: 670mm

blue: energy saving

Packaging & Delivery

| Packaging Details: | one machine in a 40GP container |

|---|---|

| Delivery Detail: | a week if it's at stock OR a month |

Specifications

1.high response 2. high precise,3oil saving 4. water saving 5.long working life

details :

LOG-400A8 | ||||

International size rating | 2860/400 | |||

INJECTION | A | B | C | |

Shot volume | cm3 | 1385 | 1810 | 2290 |

Shot weight | G | 1260 | 1646 | 2084 |

OZ | 44.1 | 57.5 | 72.8 | |

Screw diameter | mm | 70 | 80 | 90 |

Injection pressure | mpa | 206 | 158 | 125 |

Screw L:D ration | 21:1 | 21:1 | 19:1 | |

Screw stroke | mm | 360 | ||

Screw speed(stepless) | r/min | 0-135 | ||

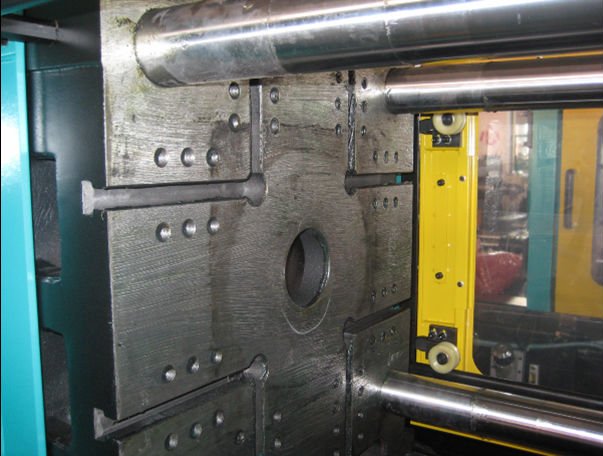

CLAMPING UNIT | ||||

Clamping force | kn | 4000 | ||

Opening stroke | mm | 670 | ||

Platen size | mm×mm | 1060×1040 | ||

Space between fie bars | mm×mm | 730×710 | ||

Mold fhickness(Min-Max) | mm | 250-730 | ||

Max.daylingt | mm | 1400 | ||

Hydraulic ejection stroke | mm | 185 | ||

Hydraulic ejection force | kn | 111 | ||

POWER UNIT | ||||

Hydraulic system pressure | mpa | 17.5 | ||

Pump motor | kw | 37 | ||

Heating capacity | kw | 32.3 | ||

Number of femp confrol zones | \ | 5+ nozzle | ||

GENERRL | ||||

Dry-cycle fime | sec | 5.1 | ||

Oil fank capacify | λ | 820 | ||

Machine dimensions | m×m×m | 8.6×1.75×2.35 | ||

Machine weight | kg | 17000 | ||

- Q: press feeding button feeding, injection machine has been feeding, storage position to still can not stop why, 15With electronic ruler control, is there an electronic ruler problem, how to judge?

- How do you determine that the feed has reached the end of the storage? Whether from the display page screw actual position to the target location is to determine if, please check whether the charging valve is electrified,

- Q: Production calculation... 60 / 60 seconds * / / 25 x 32 / sec / mold die =1 * 12 hours per hour yield = 12 small classInjection molding machine... Production calculation... 60 / 60 seconds * / / 25 / 32 / sec * die die =1 output * 12 hours = 12 hour shifts production 55075But I don't get enough output every day... Can only do 49501 pieces, ask 49501 pieces to take several hours to be able to do... How much extra time do I have to add to the production?... Urgent urgent... Can not take a day except what count how much time yield......

- 2. can not take a day except what count how much time yield......49501 / 1 hour yield = production hoursPS: personal experience, or to offer internal injection tube reported capacity of up to 23 hours of production capacity, 24h two classes, each class for half an hour maintenance and machine maintenance time is a must (of course sometimes less capacity of the interface). I used to be in accordance with 22h reported capacity, otherwise delivery can not come out, you hang up, give yourself more room.

- Q: What are the common problems and solving methods of injection molding machine? The more detailed, the better the month

- Common faults and elimination methods of injection molding machineNon locking modeA, close the front and rear door safely;B and check whether the safety threshold switch works properly;C, check the thimble recession switch;D, check mode lock electronic ruler and die stop switch;E, check mould parameter, speed, pressure and position setting is correct;F check whether the coil of the mould valve is live or not and whether the spool is working properly;G, the mold thickness adjustment or switch mode switch open, in the automatic state can not die;H, if there is a hydraulic safety lock, check whether it is normal.Open moldA and check the test status of the electronic ruler;B check whether the coil of the mould valve is live or not and whether the spool is working properly;C, if the high pressure mode locking down time is too long, because the metal structure related to the elastic deformation caused not opening, approach: a) to improve the opening speed, pressure, pressure reducing opening time, b) in general can be opened;D, if there are core pulling, twisting and other operations in the opening die, the working state of the lock die is not normal, so it is necessary to check whether the start and stop signals of these actions are normal.Die adjustmentA, mode adjustment counting switch fault;B and the original position change of the mould (in this case only one way adjustment)C, regulating valve coil is charged, and spool work is normal;D, the working state of the regulating motor;E, the die nut dies.

- Q: What should be noticed before the machine is stopped when the injection machine is finished?

- Dongguan City Zhen Ying Machinery equipment limited company to remind you: to prolong the life of the injection molding machine, usually must take good care of!

- Q: How does the injection machine exhaust?

- 1, the mold cylinder formed a negative pressure, inhalation of air from the outside. Concrete method: first, apply the butter on the joint surface of the connecting parts, make several opening and closing dies, observe whether there is any change or not. If so, tighten the screws and joints tightly.2, check whether the suction pump air. Specific methods: check whether the oil absorption port layout specifications; oil in the air will be removed.3 、 the pipeline is too long or the suction height is too high, it is difficult to exhaust. Specific method: with exhaust valve, repeatedly doing the opening and closing mold action exhaust; if not, then have to design and install a slightly (usually in the highest position).4, is it a new cylinder, or repair mold cylinder, or did not start for many days?. In this case, do more warm-up exercises, the air naturally discharged.

- Q: What does an injection maker do?

- Run injection molding machine, take products, Xiao Shui mouth, very tired, suggest you do not do well, pay little, long hours.

- Q: The first paragraph of the injection molding machine does not rise in temperature. What's the matter?

- Answer: there are several kinds of willing to 1, heating ring bad 2, line short-circuit burned 3, AC contactor damage 4, safety tube burned 5, switch trip 6, temperature line connection error or damage

- Q: How many grams of 200t injection molding machine?

- Each injection molding machine is standard with three types of screw, mainly to see requirements, the smallest less than 200g, the largest more than 300, general ABS with medium-sized screw, PA, PC with small screw, PP with large screw.Energy conservation:The energy saving of injection molding machine can be divided into two parts: one is the power part, and the other is heating part.Energy saving: most of the power inverter, energy saving way is through energy saving more than the actual motor, such as motor power is 50Hz, and you actually need only in the production of 30Hz is sufficient to produce, the extra energy is wasted, the inverter is to change the output power of the motor to achieve the energy-saving effect.

- Q: Recommend durable low pressure injection molding machines?

- Low pressure injection molding machine Dongguan tiansai Plastic Machinery Co., Ltd. has CE certification, spare parts production, stable quality, electronic components are selected GB or imported brands, and the company in accordance with ISO9001 and TS16949 quality management system, in addition to standard injection molding equipment can also be customized equipment, and the 1 year warranty. (refer to the website www.lpms of Dongguan Tian Jie plastics machinery Co., Ltd.)

- Q: What kind of after-sales service, which friends know to introduce?

- Landlord, you want to ask the best brand ah. I know

Send your message to us

Injection Molding Machine LOG-400A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords