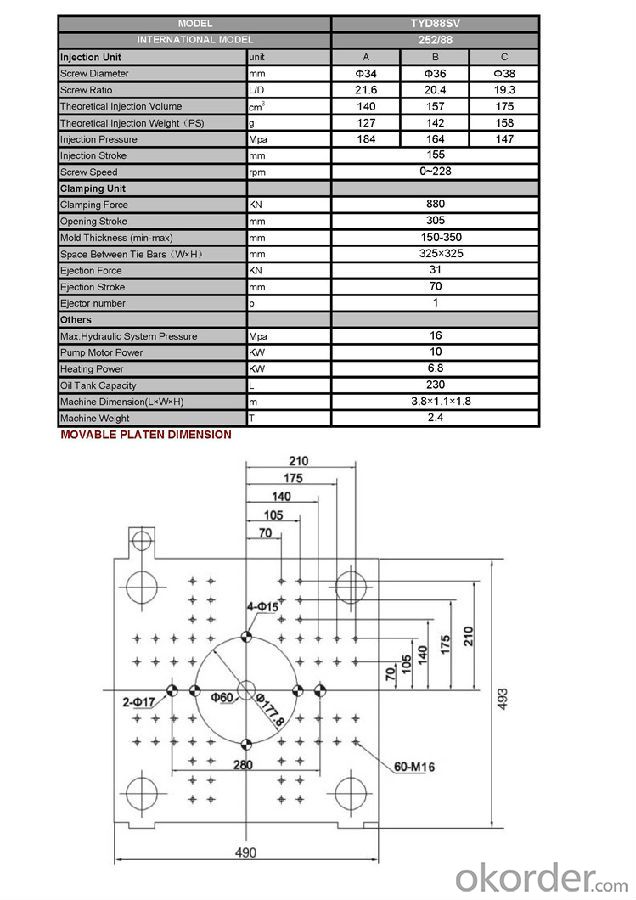

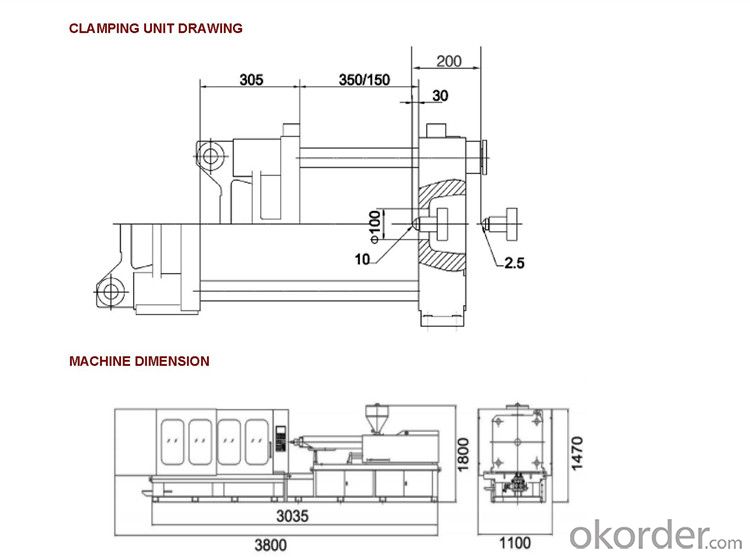

88T plastic injection molding machine TYD88SV plastic making machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

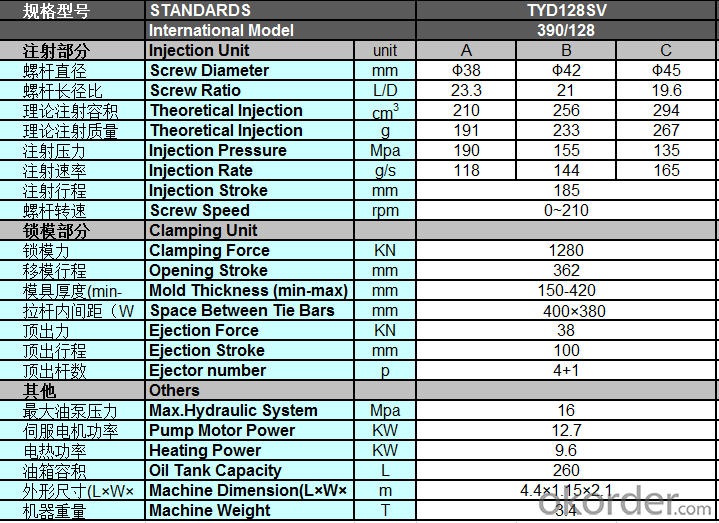

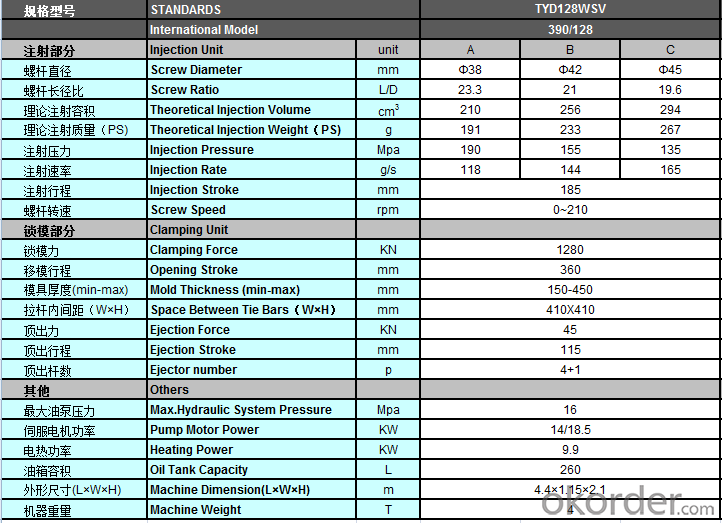

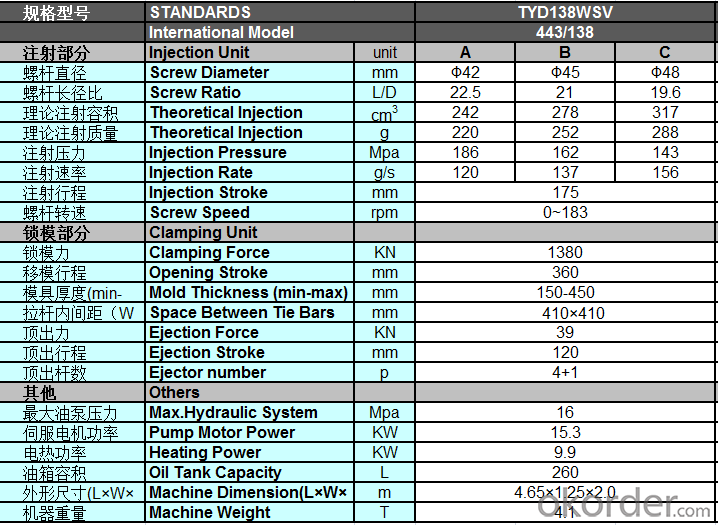

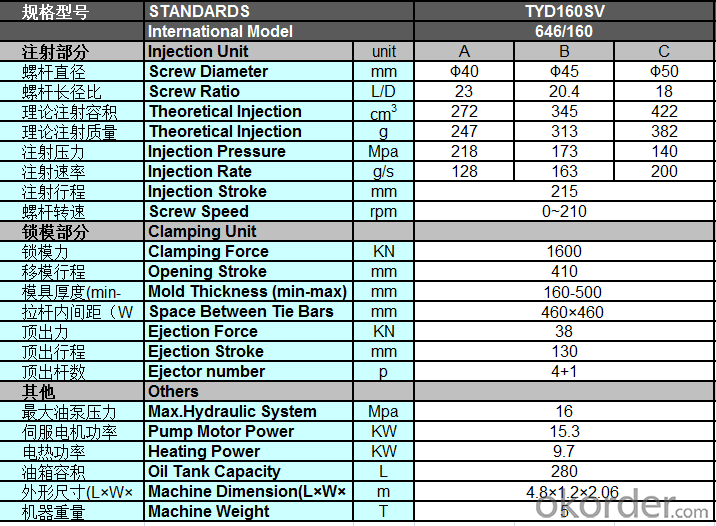

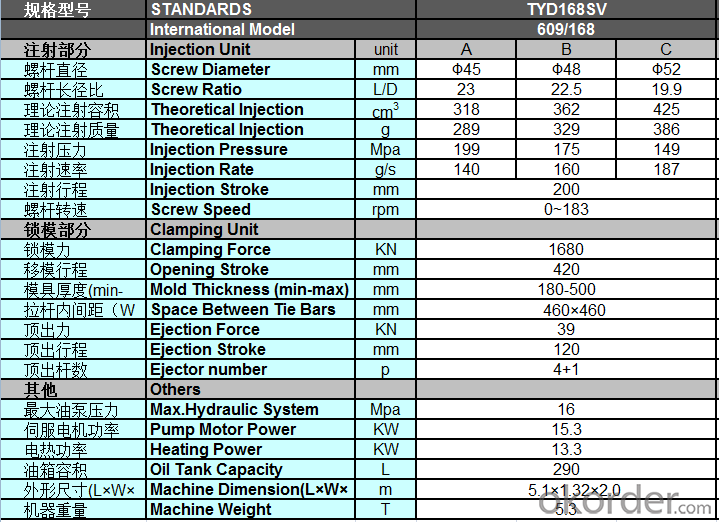

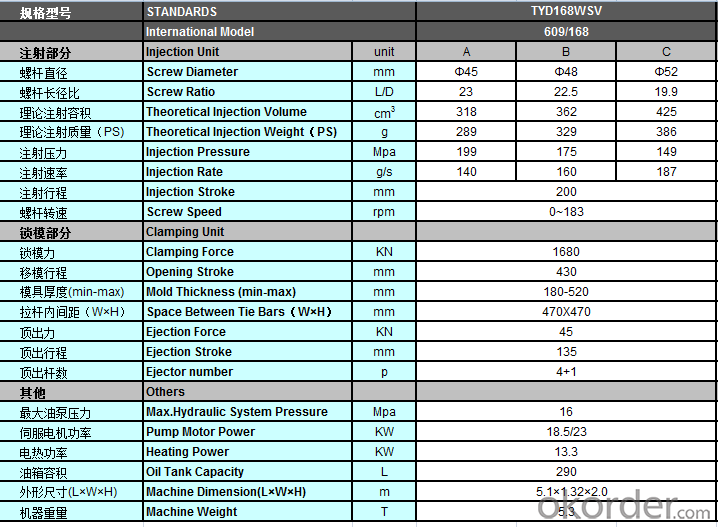

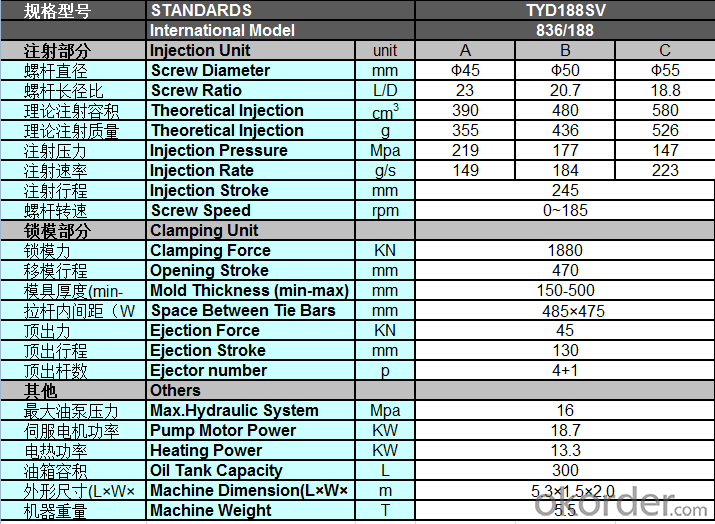

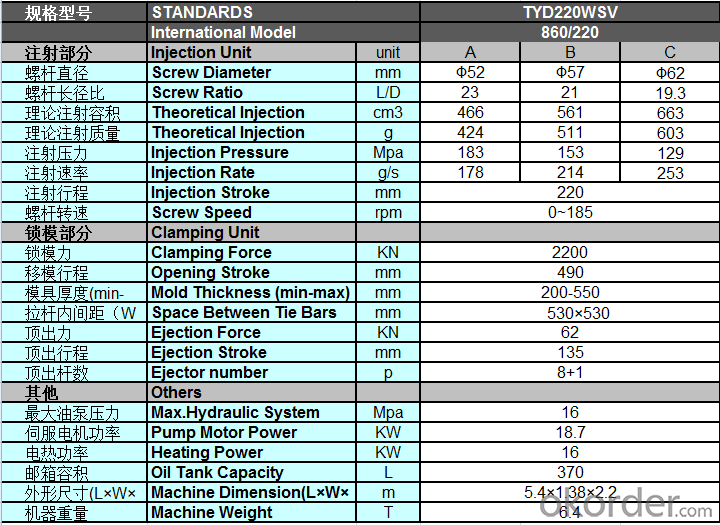

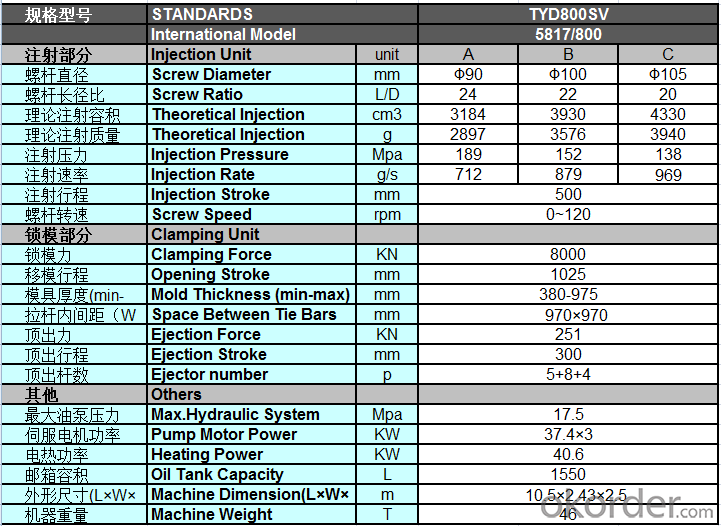

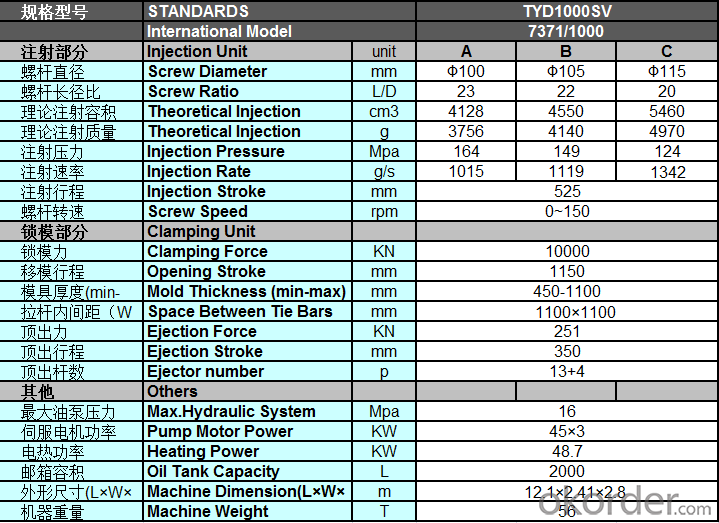

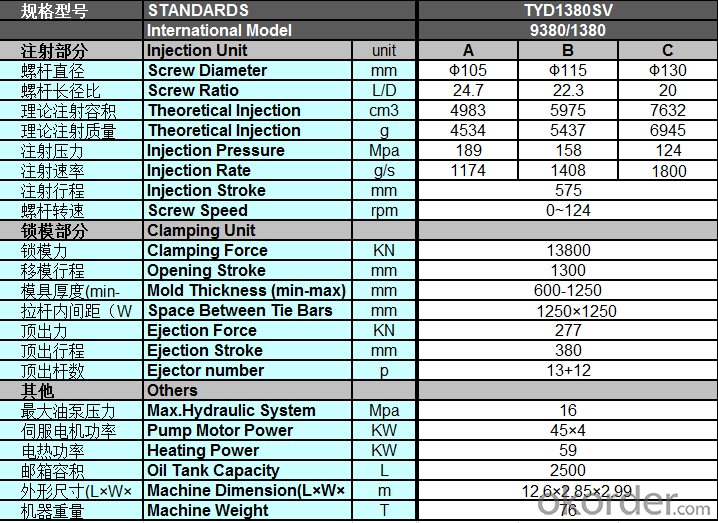

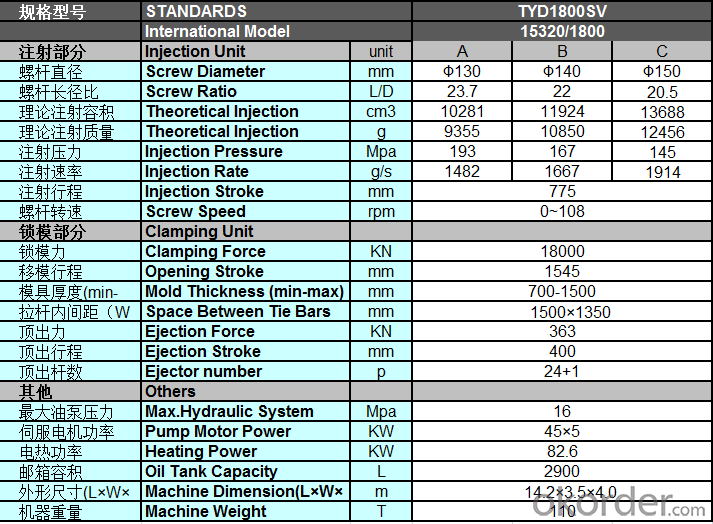

Specification

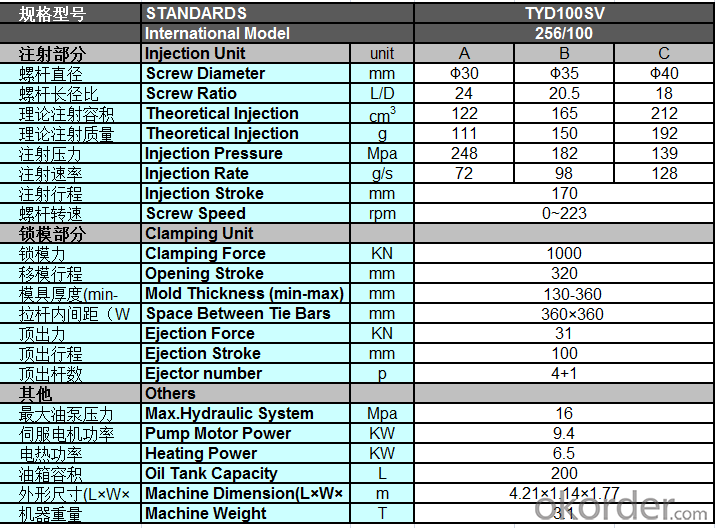

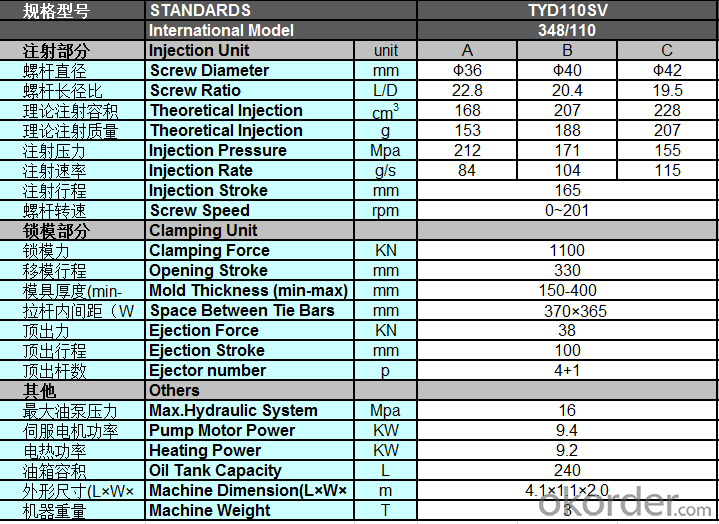

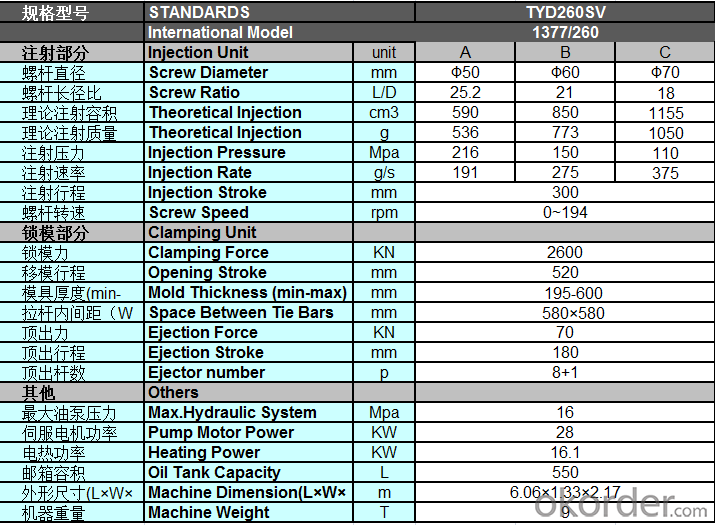

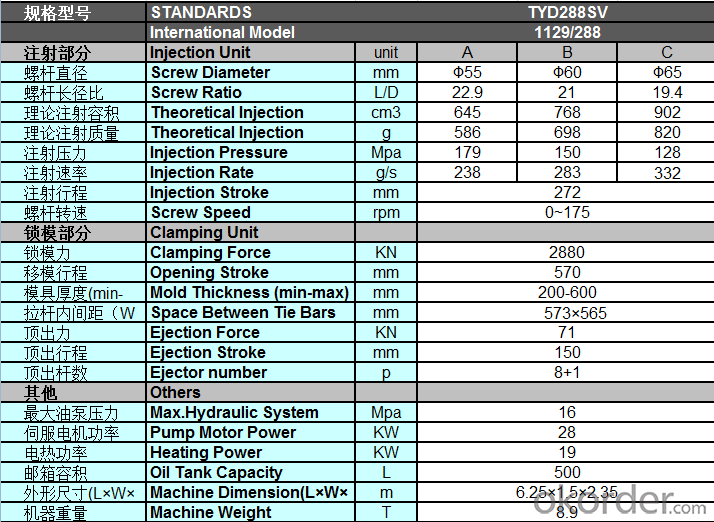

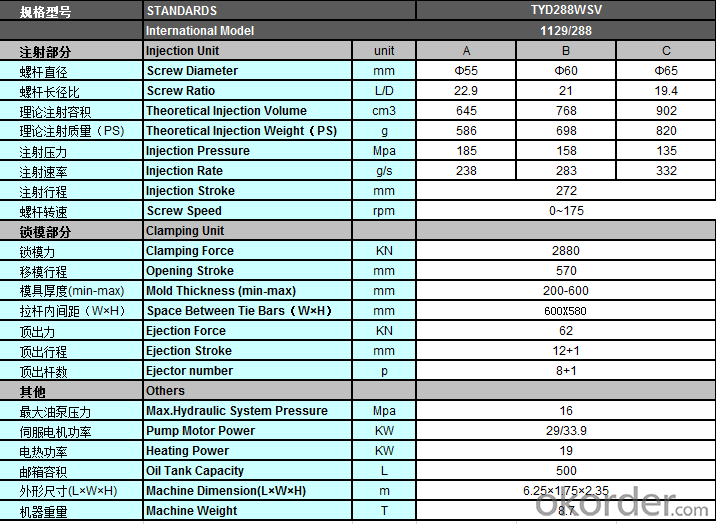

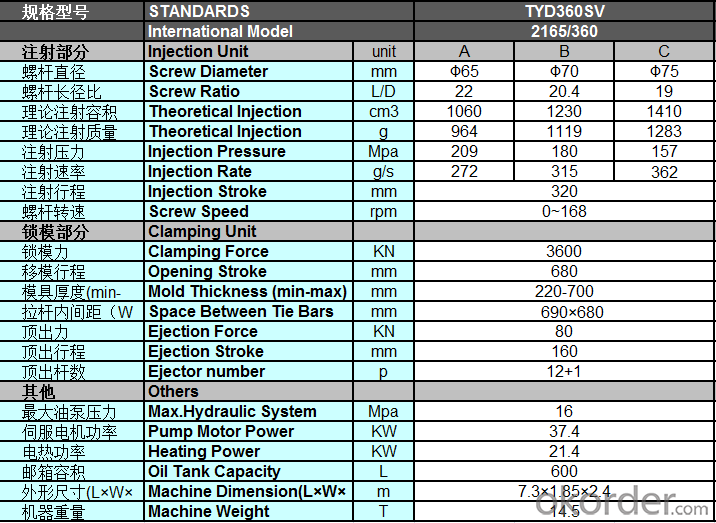

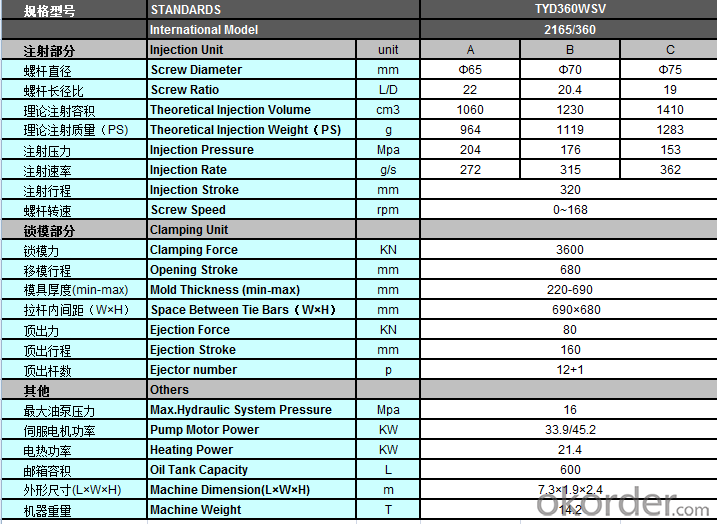

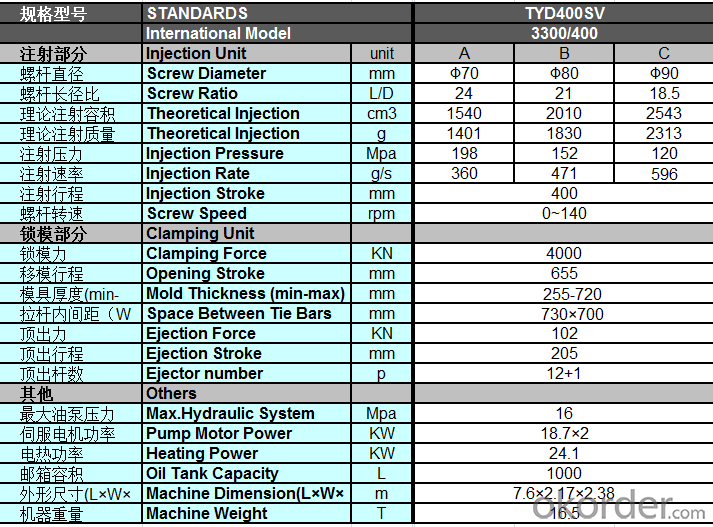

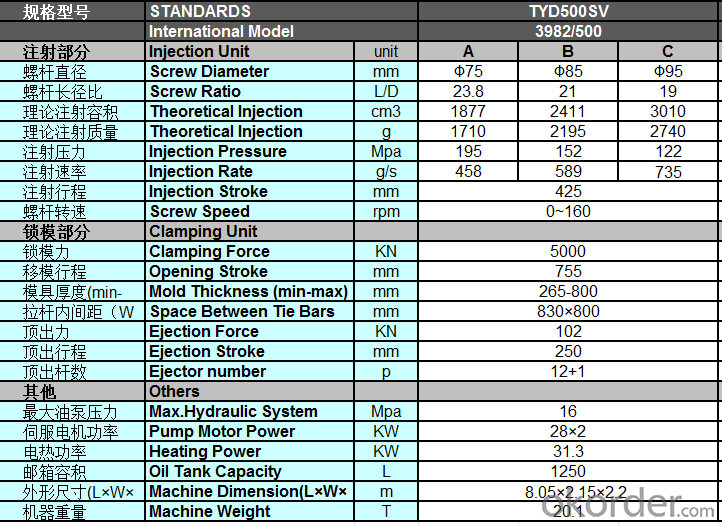

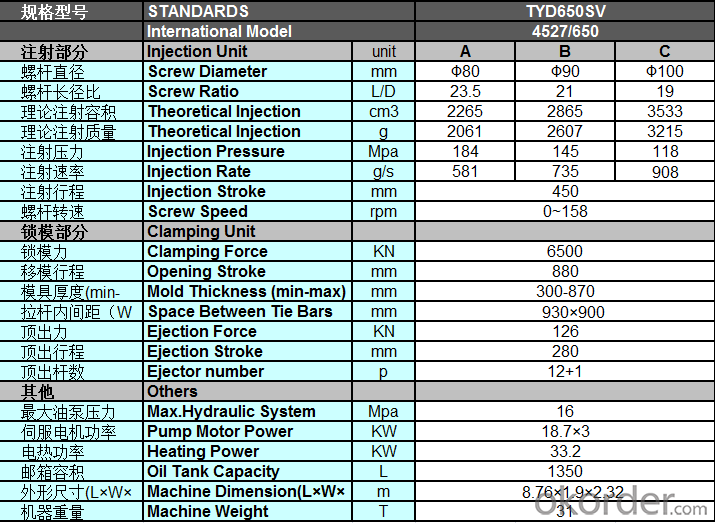

our other machine for your reference

our technical advantage

our packing:

Fine package on pallet. In case of the size and weight requirment, it will be loaded in seperated containers.

Our Services

1. Our manufactory team will help you to choose the TYD machines to match your production demand

2. We apply the OEM service to meet your production requirment

3. Our after-sale service will help you to maintain the machine in proper condition

Company Information

our factory is one of the professional plastic injection molding machinery manufactury in China

The characteristics of the machines are high efficiency and energy saving, the spec are from 50 grams to 20000 grams.

We have 100 sales and service facilities were founded in China and overseas market.

Up to now, our products have sold in Brazil, Pakistan, Russia and other places.

We have passed the ISO 9001:2008 and CE certification.

The main parts of the machine come from Germany, Italy, Japan, Taiwan and other countries.

FAQ

Q. How to choose the TYD injection molding machine?

A. It based on the mold size and mold stroke according to products weight and dimension, wall thickness, properly clamping force and combined with the injection pressure. Our work team will help you to make the good choice if you can apply the products spec.

Q. Do you OEM?

A. Yes, our OEM team would like to work with you.

Q. where is your factory location?

A. we are located in Zhoushan seacost City which is near the Shanghai and Ningbo city. your are welcome to visit our factory.

- Q: press feeding button feeding, injection machine has been feeding, storage position to still can not stop why, 15With electronic ruler control, is there an electronic ruler problem, how to judge?

- How do you determine that the feed has reached the end of the storage? Whether from the display page screw actual position to the target location is to determine if, please check whether the charging valve is electrified,

- Q: How many tons is the injection machine of 12 Ann?

- A, an abbreviation for ounce, is a unit used by the Hongkong industry to distinguish between injection molding machines. In this way, in the domestic commonly known as "T" (ton), "12" equivalent to "160T", the screw diameter of about 32 mm.

- Q: Known diameter and displacement length of screw.

- when the product is other plastic:M (other) = (1.1~1.3) * (product weight + gating system total weight)M (PS) =1.05*W (other) / P (other)1.05 is PS density unit g/cm3P (other) for other plastic density(formula: P =M/V)

- Q: How much is the ejection rate of injection molding machine?

- Generally transferred to 4, to 6 can be, I hope my answer will help you - Switek

- Q: Ready to open a small injection molding plantThere are only two machines at the moment, one 160T, one 250TProducts are note PA, PP, PU round (3, 4, 5 inches through)I would like to help you count, if 2 machines 24 hours boot, a month down, the output value of these 2 machines about how much? Thank you, the best way to calculate ~ ~!

- Take PA 30 seconds cycle, (because PA is a crystalline material, cooling time is not necessary so long) daily production for 23 hours, one hour maintenance machine, daily production of 3600/30=120*4*23=11040PCS, how to know the quality requirements. How many secrets do you have for a month? The machines are very well maintained and seldom broken.If there is no flash, try to reduce the clamping force. This reduces the machine wear and tear, and if the product requires general, you do the frozen water. The other 2 materials will speed up 10 seconds at least. Don't hesitate to ask me questions

- Q: What are the equipments around the injection molding machine?

- Under normal circumstances, the main crusher, mixer, cooling tower, dryerCan match the mold temperature machine, chiller, suction machine and so on

- Q: Injection molding machine computer maintenance where professional?

- Shenzhen Guanlan hung large injection machine repair parts Service Center; 075528085816; 13924627722 - bit o Shenzhen Longhua, Gongming Mission Hills, Pinghu, Dongguan, Tangxia, Fenggang, Cheonggye, professional injection molding machine maintenance; computer maintenance injection molding machine injection molding machine; circuit board maintenance; injection molding machine circuit, circuit, mechanical maintenance; 1) Shenzhen, Dongguan, Huizhou within the scope of domestic and imported brands of fault injection molding machine maintenance; 2) shock maintenance male injection molding machine; Chun machine maintenance; Haitian injection molding machine maintenance; elite machine maintenance; kendat machine maintenance; Schroder machine maintenance; maintenance Jia Ming Ren Xing injection molding machine injection molding machine; maintenance;

- Q: How much is the power consumption of the 80 ton injection molding machine in an hour?Plastic accessories 2 grams, the first mock exam 8, one minute can beer several times?What size of injection machine is needed for such a small fitting? 80 tons is OK?Master answer, advertising do not trouble!

- This is an estimate.Specific circumstances have changed. It might be a little lower than this. But not too much.Because the total power of the 80 ton machines is about 15 kilowatts, even if the actual use is only half, there are also 8 kilowatts.

- Q: What is low voltage protection (injection molding machine)?

- For example, when there is something on the surface of the mold to fit the mold, it will open the mold automatically in order not to damage the mold. This process is low voltage protection.

Send your message to us

88T plastic injection molding machine TYD88SV plastic making machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords