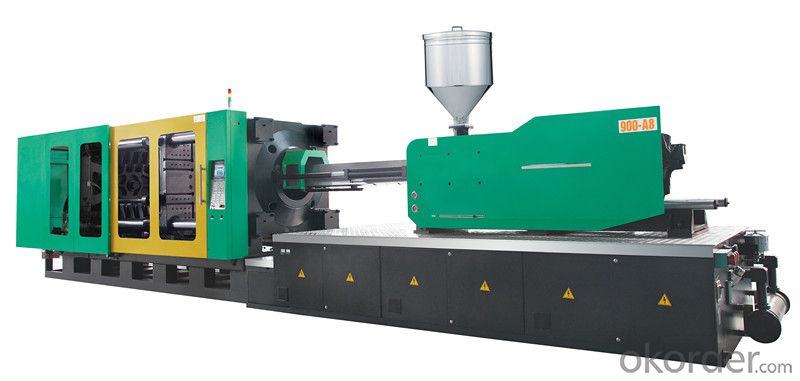

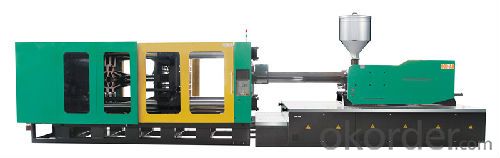

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

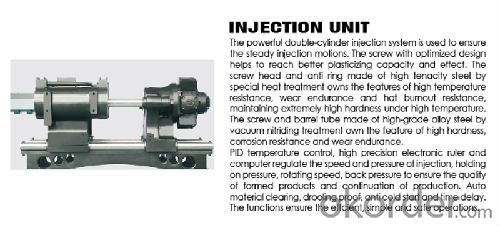

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG900-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 2893-5143g

Clamping Force: 9000kn

Opening Stroke: 1050 mm

Power(W): 37+37 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Space between Tie Bar: 1080*1030

Platen size: 1530*1530

Heating power: 58.45 kw

Oil Tank Capacity: 1900 L

Machine weight: 48T

Screw Diameter: 90-100-110-120

Ejector stroke: 300 mm

Ejector force: 270 kn

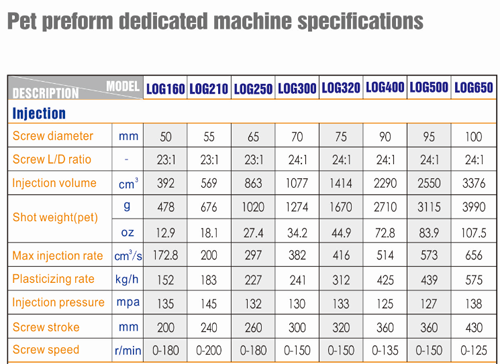

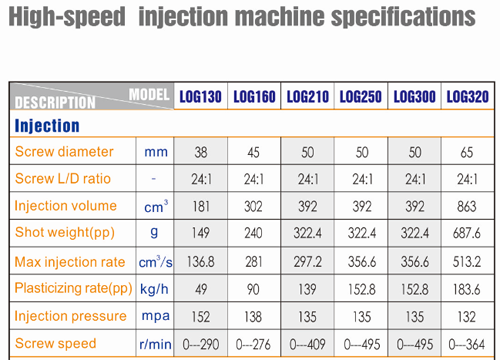

| INJECTION | LOG900 | ||||

| A | B | C | D | ||

| Shot volume | cm³ | 3179 | 3925 | 4750 | 5652 |

| Shot weight (ps) | G | 2893 | 3571 | 4321 | 5143 |

| oz | 103 | 127 | 153 | 182 | |

| Max injection rate | cm³/s | 540 | 666 | 806 | 960 |

| Screw diameter | Mm | 90 | 100 | 110 | 120 |

| Plasticizing rate | Kg/h | 291 | 378 | 503 | 600 |

| Injection pressure | Mpa | 227 | 184 | 152 | 128 |

| Screw L:D ratio | 22:01 | 22:01 | 20:01 | 18.3:1 | |

| screw speed | r/min | 0-120 | |||

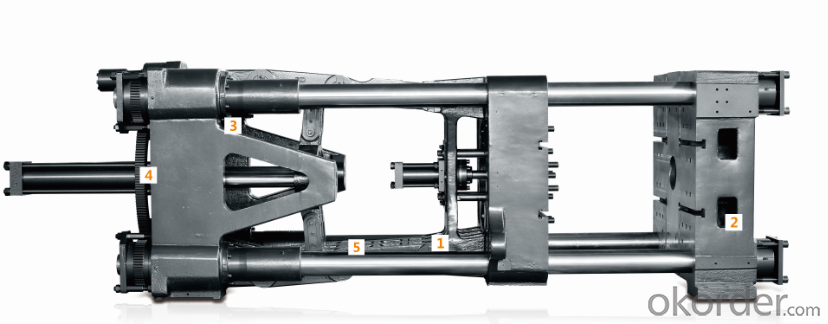

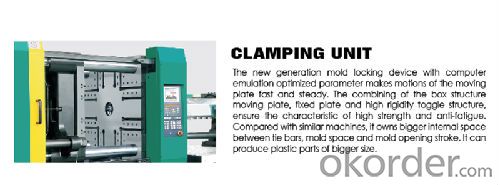

| CLAMPING | |||||

| Clamping force | Kn | 9000 | |||

| Opening stroke | Mm | 1050 | |||

| Platen size | MmXmm | 1530*1530 | |||

| Space between tie bars | MmXmm | 1080*1030 | |||

| Mold thickness (Min-Max) | Mm | 400-1100 | |||

| Hydraulic ejection stroke | Mm | 300 | |||

| Hydraulic ejection force | Kn | 270 | |||

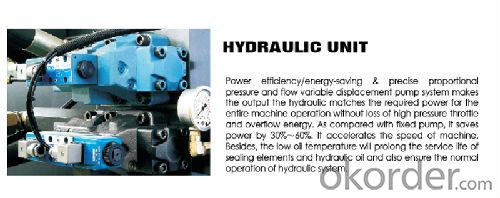

| Power Unit | |||||

| Hydraulic system pressure | Mpa | 17.5 | |||

| Pump motor | Kw | 37+37 | |||

| Heating capacity | Kw | 58.45 | |||

| Number of temp control zones | 6+ (nozzle) | ||||

| GENERAL | |||||

| Dry-cycle time | sec | 8 | |||

| oil tank capacity | L | 1900 | |||

| Machine dimensions | Mxmxm | 11*2.4*3.5 | |||

| Machine weight | kg | 48000 | |||

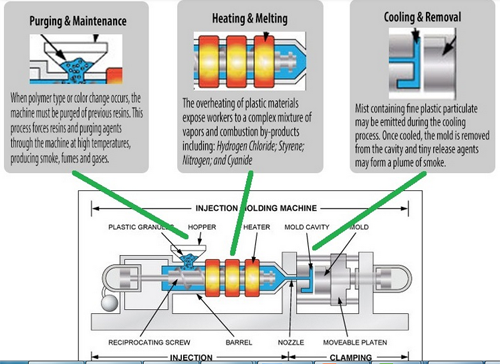

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q: Can carbon fiber be used for injection molding?

- Carbon fiber can be used for injection molding, and the typical product is CF+PPS. Carbon fibers are difficult to process two times, such as drilling on molded products, plain drills, drilling holes, and drilling bits. Therefore, in the part design to avoid two machining. In addition, as with plastic and glass fiber, and carbon fiber after the screw injection molding machine screw wear increases, the life expectancy was shortened. Global carbon fiber technology and production are still largely in the hands of Japan and the United states. There are less than 20 countries and regions that can realize the industrialization of carbon fiber in the world. There are no more than 12 large-scale production enterprises. Dongli, Japan, the United States and Japan's Toho Zoltek Japan MITSUBISHI rayon is global carbon fiber production capacity of the top four manufacturers, which accounted for four of the total global carbon fiber capacity 23.4%, 17.1%, 14.3% and 10.3%, and China enterprises accounted for only 4.3%. The global carbon fiber production is mainly based on PAN based carbon fiber. In 2009, PAN based carbon fiber production capacity accounted for about 96% of the total carbon fiber production capacity of the world. The concrete application of carbon fiber shows that "the structure of electronic products, the characteristics of materials and the method of their selection" (people's Posts and Telecommunications Press, 2010.4)

- Q: Renovation and maintenance treasure source injection molding machine material pipe screw how much?

- This simple to: remove the barrel wall need to stick with the smooth talking drum material original material rod slightly special barrel trim surface treatment like new repair gas cylinder can influence

- Q: What measures can be taken to shorten the molding process cycle of injection molding machines?

- Reduce the mold temperature, reduce the heating temperature of the cylinder, increase the speed of die closing, shorten the cooling and holding time, reduce the time of back compression and short sol, and speed up the movement with mould opening

- Q: How much does the 280T injection machine consume?

- TOSN San Jin Technology (Shenzhen) Co., Ltd is a company dedicated to the low pressure cold molding process (low injection), low temperature and cold cold low pressure injection molding machine, injection mold, LED packaging, wire encapsulation, electronic packaging, hot melt adhesive material of the latest research and development of production of T08H, T08F type low pressure cold injection the structure of needle machine, vertical pump integration, grab the rubber head, a rubber cylinder never leak adhesive!

- Q: Not computer, there is a proportional current. The whole machine has no hydraulic operation and the pressure gauge is zero.

- 2 、 injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: Large injection molding machine to block reuse

- First you have to put the head while hot into slices,

- Q: Excuse me: what are the differences between injection molding and extrusion?

- Injection molding machine is by injecting plastic particles into the closed cavity, filled with the cavity after the suspension of work, by cooling the plastic into a certain shape, after opening the mold again. Such as plastic cups, plastic basins, plastic shells of various complicated situations and so on. He has a limited amount of injection per cycle.Extruder is through the plastic particles after the warm, through the mold continuous extrusion, such as plastic pipes, plastic plates, plastic bars and so on. It can be extruded into very long products without the limitation of cycle time.

- Q: The products produced by injection molding machines include flying edge, burn and burn

- Hello, my friend! These three problems are unlikely to appear on the same product. Because you ask the question is more general, have to obscure answer, for reference only. 1, flying edge: with higher sol temperature, low mold pressure, the mold itself is related to the problem. 2, burns and burns are generally caused by poor exhaust problems, you can adjust the injection speed, adjust the clamping force, improve the exhaust situation to solve. May ask again. Please make the question more specific and easy to answer. For reference only.

- Q: The temperature of the injection molding machine: 1 220.2 210.3 200.4 190.5 175 period, when heated, everything is normal, but when the temperature reaches the set value of the motor work, work to about 15~20 minutes, 3 and 4 of the temperature began to rise slowly to 213~220 (lead injection unstable), other Dan normal. Then the motor is switched off, stop, about 15 minutes later, the 3 and 4 section temperature began to slowly fall to the set value, please master: what is the reason? How to solve?

- Hello:You can lower the feed rate a little, and there is a big wear on the material and the cylinder.

- Q: My company bought several days to fully send the injection molding machine! Secondhand! What seems to be a small barrel?! 600t's injection molding machine seems to be about the same size as the Haitian 160t in our factory! But the motors are big! 600t motors have 77kw! What's more, there are two cylinders in the part of the machine that I don't know what to use!!Don't look for the production of daily necessities but also bought no way only to re make a barrel of the two cylinders is said to have a small pump oil to two cylinders to increase the pressure to speed up not by nitrogen small motor without the proportional valve directly into the cylinder direct injection to do it ordinary machine line

- This is a high-speed machine, do daily necessities certainly not, the amount of plastic is too small, and too much electricity, if you want to sell,

Send your message to us

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords