Injection molding machine LOG-500S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Condition: New

Type: Other

Style: Horizontal

Brand Name: LOG

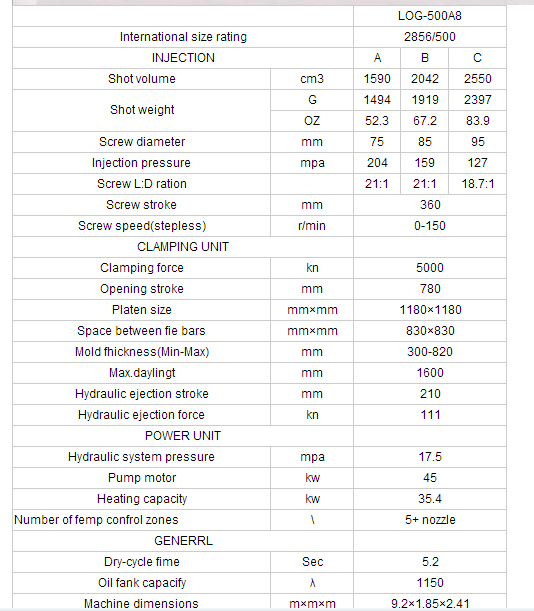

Model Number: LOG-500S8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 1494---2397G

Injection Rate: >100MM/S

Clamping Force: 5000KN

Opening Stroke: 820mm

Power(W): 37kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

- Q: What kind of lubricant does the injection machine use?

- Ann beauty injection molding machine hydraulic oil HM68 number.

- Q: How to debug the injection molding machine? solve

- Learning injection machine, please refer to unilateral, all aspects of 3 days and 3 nights also can not be finished. Injection molding machine instructions on the injection of two words, which have a lot of knowledge, according to different problems to debug, and sometimes a problem may be]

- Q: What are the common problems and solving methods of injection molding machine? The more detailed, the better the month

- Common faults and elimination methods of injection molding machineNon locking modeA, close the front and rear door safely;B and check whether the safety threshold switch works properly;C, check the thimble recession switch;D, check mode lock electronic ruler and die stop switch;E, check mould parameter, speed, pressure and position setting is correct;F check whether the coil of the mould valve is live or not and whether the spool is working properly;G, the mold thickness adjustment or switch mode switch open, in the automatic state can not die;H, if there is a hydraulic safety lock, check whether it is normal.Open moldA and check the test status of the electronic ruler;B check whether the coil of the mould valve is live or not and whether the spool is working properly;C, if the high pressure mode locking down time is too long, because the metal structure related to the elastic deformation caused not opening, approach: a) to improve the opening speed, pressure, pressure reducing opening time, b) in general can be opened;D, if there are core pulling, twisting and other operations in the opening die, the working state of the lock die is not normal, so it is necessary to check whether the start and stop signals of these actions are normal.Die adjustmentA, mode adjustment counting switch fault;B and the original position change of the mould (in this case only one way adjustment)C, regulating valve coil is charged, and spool work is normal;D, the working state of the regulating motor;E, the die nut dies.

- Q: How to reset the EM-120 origin of the injection machine?

- Two 、 brief introduction of injection molding machine:Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.This answer is classified by the scientific education, Zhen Zhen afterwards recommended

- Q: What is the gear adjustment and chain adjustment of the injection molding machine?

- It is the die adjusting mechanism on the tail plate of the injection molding machine. The gear adjusting die is to drive a big gear with a regulating motor, and then the big gear drives the four small gears on the forest column to realize the adjustment and advance of the die. The chain adjustment is to adjust a motor to drive a chain, and then drive a few small gear.

- Q: When the injection machine is ejected, does the screw screw rotate?

- We call it a battery, and I don't know what you call it

- Q: What is the back pressure in the injection molding machine?

- Jin Xin offers you:Jin Xin explain the injection molding machine screw back pressure what role?Back pressure allows the screw to produce enough mechanical energy in the rotation of the reset to melt and mix the plastic, and the back pressure has the following uses.The volatile gases, including air, are discharged to the outer cylinder.Mix the additives (e.g., toner, color, antistatic agent, talc, etc.) and melt evenly.Homogenizing the melt flowing through different screw lengths.Providing uniform and stable plasticizing material to obtain accurate weight of finished products.The back pressure can make up the melt temperature of injection molding machine barrel, rise and set pressure value associated with a large injection molding machine, screw diameter more than 70mm [(2.75in) of the oil pressure can be up to 2.5-4MPa], but need to pay attention to the oil pressure is too high, or is caused by the melt pressure back pressure resistance induction high temperature molten material in the barrel is too high, this kind of situation for heat sensitive plastics production is destructive.And too high back pressure also caused excessive screw and irregular offside, so that the amount of plastic is very unstable. The viscoelastic properties of offside and plastic screw the screw; offside and melt the stored energy. The more energy, the greater the offside screw distance, the energy stored in the screw stops rotating, suddenly beat back, some thermoplasticPlastic beating phenomenon is more severe than other plastic, such as LDPE, HDPE, PP, EVA, PP/EPDM composite and PPVC, compared with GPPS, HIPS, POM, PC, PPO - M and PMMA, more prone to beating phenomenon. For optimum production conditions, the correct back pressure setting is critical. Proper back pressure setting allows the mixture to be properly mixed, and the offside range of the screw does not exceed 0.4mm (0.016in).

- Q: I want to know something about the purchase of high-end injection molding machinesCustomers in the whole power and hydraulic injection molding machine purchase process, those machine advantages, they are more concerned about, and if you choose to buy, then you will choose all electric or full hydraulic machine, why? To know a friend told me, we discuss together, thanked the boy in this

- All electric injection molding machine, injection molding machine Dongyang (TOYO), Sadegh (Sodick), FANUC injection molding machine injection molding machine (Fanuc)Day steel injection molding machine (JSW), Ke Chun injection molding machine (KeJun), two-color injection molding machine.

- Q: Introduction to injection molding

- Injection molding is a method of producing shapes in industrial products. Products are typically molded by rubber injection and plastic injection. Injection molding can also be divided into injection molding, die casting and die casting. Injection molding machine (referred to as the injection molding machine or injection molding machine) is plastics molding equipment of thermoplastic or thermosetting material using plastic mold made of various shapes, injection molding by injection molding machine and mold.

- Q: Domestic injection molding machine which brands are better?

- The sea, the Haida, the shock,High exposure... Shock bear, Iraq's secret, Bo Chuang, Donghua

Send your message to us

Injection molding machine LOG-500S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords