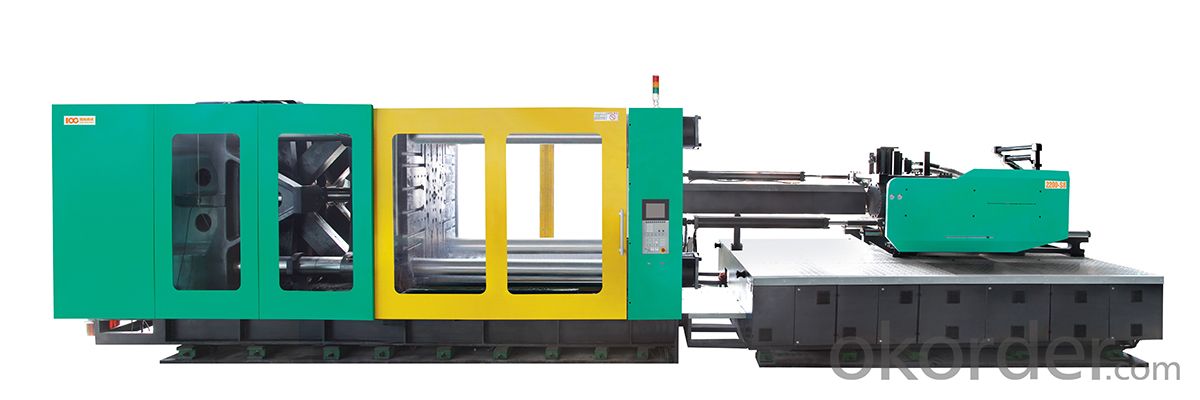

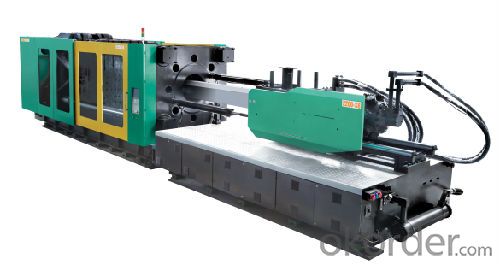

Injection molding machine LOG-2200S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 22000g

Clamping Force: 22000 kw

Power(W): 150 kw

Certification: ISO9001:2008

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Delivery Detail: | 75 days |

|---|

Description | Unit | LOG-2200A8 | ||||

international recognized models | ||||||

injection | B | C | D | |||

Tjeoretical injection volume | cm³ | 13183 | 15000 | 16933 | 24192 | |

Shot volume | g | 12043 | 13700 | 15468 | 22075 | |

Oz | 442 | 480 | 542 | 774 | ||

Screw diameter | mm | 150 | 160 | 170 | 185 | |

Injection diameter | mpa | 186 | 164 | 145 | 153 | |

Screw L:D ratio | 23.5:1 | 22:1 | 20.7:1 | 22:1 | ||

Scerw steoke | mm | 750 | 900 | |||

Screw rotate speed | r/min | 0-80 | 0-60 | |||

CLAMPING UNIT | ||||||

Clamping force | kN | 22000 | ||||

Opening stroke | mm | 1850 | ||||

Platen size | mm*mm | 2450*2300 | ||||

Space between tie bars | mm*mm | 1750*1600 | ||||

Maldthickness | mm | 700-1700 | ||||

Platen Mix stroke | mm | 3550 | ||||

Ejection stroke | mm | 420 | ||||

Ejcetion force | kN | 550 | ||||

Power/Elcetric Heating | ||||||

Hydralic system pressure | Mpa | 17.5 | ||||

Pump motor | kw | 37*4 | ||||

Heating power | kw | Nozzle | 135 | |||

Number of temp.conteol | 7+nozzle | |||||

Other | ||||||

Cycle time | sec | 18 | ||||

Tank volume | L | 4100 | 4100 | |||

Machine dimesions | m*m*m | 17.5*4.2*3.7 | 18.5*4.8*4.3 | |||

Weight of machine | kg | 136000 | ||||

Packaging & Shipping

- Q: How will the screw speed of injection molding machine be adjusted slowly?

- In the screw speed adjustment, from the lower speed start, gradually commissioning to higher speed, and then determine the screw speed.The working speed of the screw of the injection machine is unstable and is affected by the following factors:1, drive V belt wear seriously, slipping when working.2, V belt drive belt wheel center distance is too small, so that belt drive can not and belt pulley trapezoidal slope correct friction drive work.3. The temperature of the heating material in the barrel is low, and the material is not uniform, which leads to the screw rotation of the injection machine, the increase of the working load torque, and the instability of the screw speed of the injection molding machine.4, injection molding machine screw thrust bearing damage, etc..

- Q: What kind of lubricant does the injection machine use?

- Mainly used hydraulic oil, hydraulic systems for lubrication and workOther bearing grease, if gear box, use gear oil

- Q: In the plastic injection molding machine barrel, why there are so many bubbles?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.Injection molding machine barrel in the bubble is mainly divided into the following categories:Air bubble: the screw speed is too fast or the size of particles, irregular shape of the grinding material and other reasons, causing the raw material feeding time and space, gas is involved in the trip bubble.Water vapor bubbles: raw materials poor drying moisture content is too high, resulting in a large number of water entering the water vapor bubble formation in the barrel.Gas bubbles: raw material heating temperature is too high or too long residence time in the barrel (long heating time) caused by material degradation produce gas, gas bubbles travel.

- Q: How does the injection machine exhaust?

- On the system pressure plate there is a relief valve, the valve head at the top of the six angle bolts loose on it

- Q: What does an injection maker do?

- Run injection molding machine, take products, Xiao Shui mouth, very tired, suggest you do not do well, pay little, long hours.

- Q: What kind of after-sales service, which friends know to introduce?

- I knowChasing the answerThe best thing is the company's low pressure injection molding machine, and many famous brands are looking for them to process low voltage injection molding machines, such as apple, Microsoft, and the United states.

- Q: Is this an injection molding machine?

- productThe injection molding machine is the use of plastic processing machinery industry's largest production, not only have a direct injection molding machine a large number of products available, key equipment and composition of injection stretch blow moulding. China has become the world's first big pieces of plastic production, promote the cause of the development of China injection molding machine equipment manufacturing industry is in: one is the joint venture and technical cooperation with international famous enterprises; two is Chinese enterprises gradually adapt to the international procurement of mechanical parts, master the procurement channels. At the same time, the production of injection molding machine in our country also shows a strong regional characteristic. Zhejiang, Ningbo and Guangdong in Dongguan have become the important production base of injection molding machine in our country and even the whole world.

- Q: What is the meaning of injection molding machine before melting and pumping and after melting? What's the function of 10?

- Injection molding machine melting process is through the rotation of the screw, the material inside the bucket through the screw to the front end of the screw rod propulsion, screw rotation is not only itself active back, when the barrel material is pushed to the front end of the screw in the front of the barrel, the pressure will be more and more, will be forced to retreat when the screw, screw back the set position, the screw stops rotating, melt end. In order to prevent the pressure in the barrel is too large but the glue flows out from the nozzle, usually used to pumping (also called loosening, cable, shot back down), the active screw back a certain distance (usually a few mm) to remove part of the pressure.

Send your message to us

Injection molding machine LOG-2200S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords