Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG300-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 673-980g

Clamping Force: 3000 kn

Opening Stroke: 570 mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Plastic Rubber Injection Moulding Machine

Warranty: One Year

Material: Stainless Steel

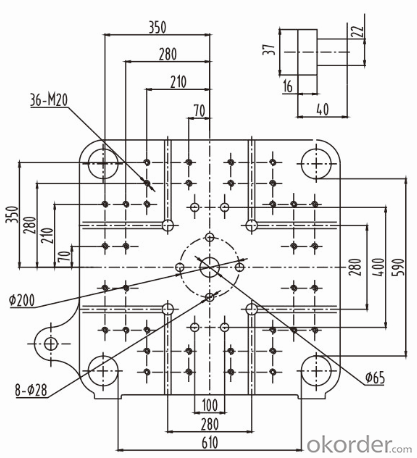

Space between Tie Bar: 610*590

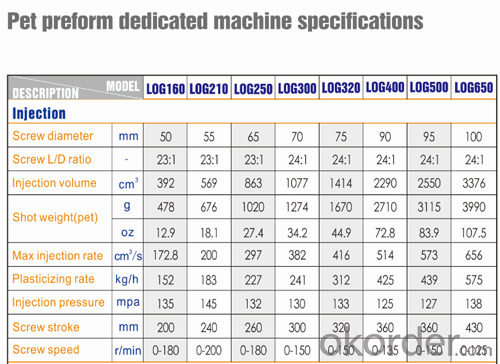

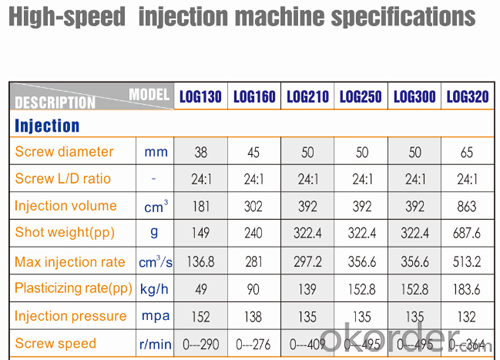

Screw Diameter: 58-65-70 mm

Machine weight: 9.1T

Ejector stroke: 160mm

| Description | Unit | LOG-300A8 | ||

| international recognized models | 1400/300 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 740 | 929 | 1077 |

| Shot volume | g | 673 | 845 | 980 |

| Oz | 23.5 | 29.5 | 34.2 | |

| Screw diameter | mm | 58 | 65 | 70 |

| Injection diameter | mpa | 190 | 151 | 130 |

| Screw L:D ratio | 24:01:00 | 22:01 | 20:01 | |

| Scerw steoke | mm | 300 | ||

| Screw rotate speed | r/min | 0-150 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 3000 | ||

| Opening stroke | mm | 570 | ||

| Platen size | mm*mm | 870*850 | ||

| Space between tie bars | mm*mm | 610*590 | ||

| Maldthickness | mm | 200-600 | ||

| Platen Mix stroke | mm | 1170 | ||

| Ejection stroke | mm | 160 | ||

| Ejcetion force | kN | 77 | ||

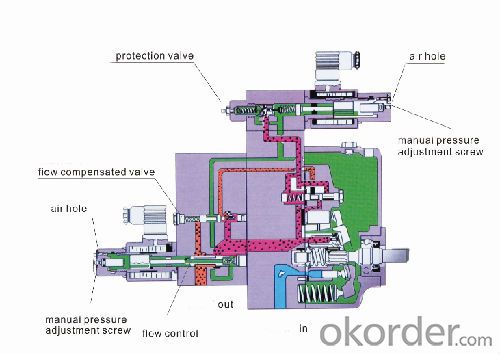

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 29 | ||

| Heating power | kw | 23.6 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5 | ||

| Tank volume | L | 380 | ||

| Machine dimesions | m*m*m | 6.4*1.6*2.18 | ||

| Weight of machine | kg | 11000 | ||

Packaging & Delivery

| Packaging Details: | Packaging Details: 20 GPcabinet Delivery Detail: In one week after get payment |

|---|

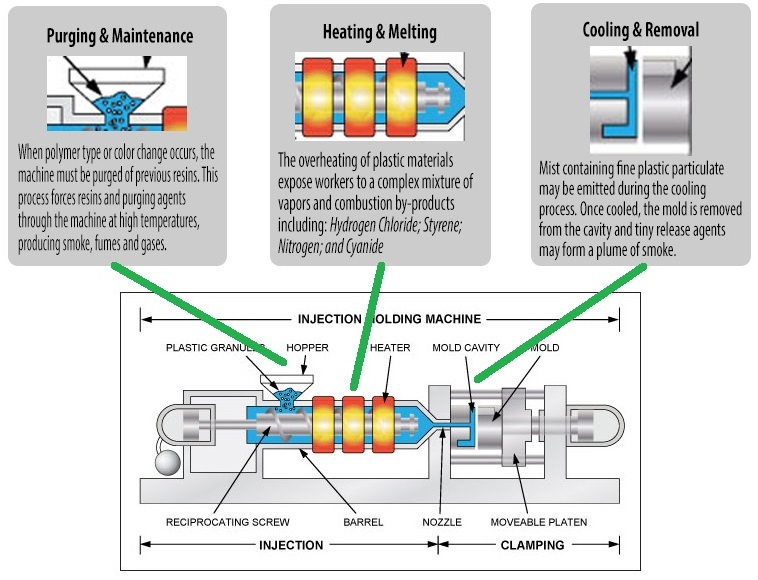

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

- Q: What injection molding machine is good?

- The vision for the company: "based on independent research and development, production and sales of plastic injection molding machine to become the first in the world of manufacturing enterprises,Actively lead the new trend of industry development."December 2006, Haitian Holdings Limited successfully listed on the SEHK (Hongkong stock exchange), initial public offering of shares.In August 2007, Haitian International Holdings Limited acquired Germany zhafir Plastics Machinery Manufacturing Co. ltd..Click hereChinese Machinery Association unitPresident of the Ningbo Association of machine unit

- Q: List of injection molding machines

- The best is Germany, Abog (formerly known as Albemarle, but by others to register the other German brand ARBURG): Baden Rumsfeld BATTENFELD;

- Q: Which country was the injection machine invented in?

- It should have been invented in GermanyIn 2008 the global injection molding machine exports amounted to $5 billion 460 million, of which Germany injection molding machine industry scale ranks first in the world, total exports accounted for more than 20% of the total exports in the world, in a dominant position in the global competition in injection molding machine.Italy and Japan were ranked second, third. The export share of American injection molding machines has dropped year by year, down from 9.8% in 2000 and 5.3% in 2008.Japan's electric injection molding machine occupies an important position in the world, of which the proportion of electric injection molding machines in North America has reached about 30%.European and American injection molding machine mainly to precision injection molding machine, large-scale injection molding machine, such as high-tech, high value-added models mainly.After years of introduction of technology and technological innovation, China machinery industry in the field of low-end injection molding machine, manufacturing level has not much difference between with the developed countries, together with the labor price advantage, the low-end export Chinese injection molding machine occupies the half of the country in the world.

- Q: What brands of injection molding machines are there in Taiwan?

- Brand: Taiwan Zhenxiong, earthquake strong, quanlifa, Taichung, Baisu, Cong Wei, Huaqin, Yinai, Nan Rong, Maria fuqiangxin precision machine, etc.

- Q: In the plastic injection molding machine barrel, why there are so many bubbles?

- There are two kinds of pores in the material. The first one contains moisture, and the raw material should be dried completely before processing, or at least 5% of the drier will be added during processing. The second is the material decomposition, to reduce the barrel temperature, reduce the melt pressure and speed, set the melt back pressure, but not too high; or adding appropriate amount of stabilizer in the raw material, it is not only a refueling.

- Q: What is the back pressure in the injection molding machine?

- Jin Xin offers you:Jin Xin explain the injection molding machine screw back pressure what role?Back pressure allows the screw to produce enough mechanical energy in the rotation of the reset to melt and mix the plastic, and the back pressure has the following uses.The volatile gases, including air, are discharged to the outer cylinder.Mix the additives (e.g., toner, color, antistatic agent, talc, etc.) and melt evenly.Homogenizing the melt flowing through different screw lengths.Providing uniform and stable plasticizing material to obtain accurate weight of finished products.The back pressure can make up the melt temperature of injection molding machine barrel, rise and set pressure value associated with a large injection molding machine, screw diameter more than 70mm [(2.75in) of the oil pressure can be up to 2.5-4MPa], but need to pay attention to the oil pressure is too high, or is caused by the melt pressure back pressure resistance induction high temperature molten material in the barrel is too high, this kind of situation for heat sensitive plastics production is destructive.And too high back pressure also caused excessive screw and irregular offside, so that the amount of plastic is very unstable. The viscoelastic properties of offside and plastic screw the screw; offside and melt the stored energy. The more energy, the greater the offside screw distance, the energy stored in the screw stops rotating, suddenly beat back, some thermoplasticPlastic beating phenomenon is more severe than other plastic, such as LDPE, HDPE, PP, EVA, PP/EPDM composite and PPVC, compared with GPPS, HIPS, POM, PC, PPO - M and PMMA, more prone to beating phenomenon. For optimum production conditions, the correct back pressure setting is critical. Proper back pressure setting allows the mixture to be properly mixed, and the offside range of the screw does not exceed 0.4mm (0.016in).

- Q: What do you mean by the number of beers produced by an injection molding machine?

- The number of beers produced by an injection molding machine means how many components can be formed at one injection.In general, each beer refers to the number of products taken out of the injection molding machine (including nozzles and products). This is usually a 1*1 hole number, a beer products =1 products; if it is 1*2 hole number, then a beer =2 products, and so on, and so on. And if it is two-color machine, then the molding is two times after a beer, the other is the same.

- Q: What is TMC injection molding machine?

- In the nearly thirty years of history not only provides customers with world-class quality products, but also provide perfect technical service, won good reputation in the region has become one of the suppliers in Asia successfully enter the market.In the field of injection molding, "TMC" has almost become synonymous with Asian brands. "Precision, stability, reliability and longevity" is the capital of "TMC" to win foreign markets. In 1994, Guangdong Jiangmen Qing excellent electrical and Mechanical Co., Ltd. as Taiwan Qing industrial Limited by Share Ltd in China's professional factories in China on the ground to take root, germination. In the past ten years, Jiangmen celebrated Taiwan as the best and the advanced technology in the world. It was a challenger, chasing the advanced technology of Europe, America and Japan, so as to perfect and innovate constantly.

- Q: Advantages and disadvantages of horizontal injection molding machines and vertical injection molding machines?

- 1. horizontal machine has the advantages of high operation, convenience, high safety performance, large bearing size and so on. The disadvantage is that the floor space is large and the price is relatively high. Suitable for medium and large moulds.

- Q: How does the product mix?

- Friends note plastic flowers (silver or silver) of good hope to help?Silver good resolution?Production of raw materials: good drying. The heating barrel degassing Liang (water, gas, volatile, etc.), gas burning retention solutions, mould heating involved (including type changes are good flesh) shaped silver prototype surface show silver floating flow area not only limited traces of silver near the gate of primary and reflected out parts closely related, must understandTwo. Production: the so-called silver silver diagram shown in figure refers to the molten resin in bubbles, tensile effect of muscle strips flow marks because of the appearance of the silver bullion that look like muscle strips

Send your message to us

Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords