Industrial Silicon Wafer Solar Cells / 156mm Mono Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

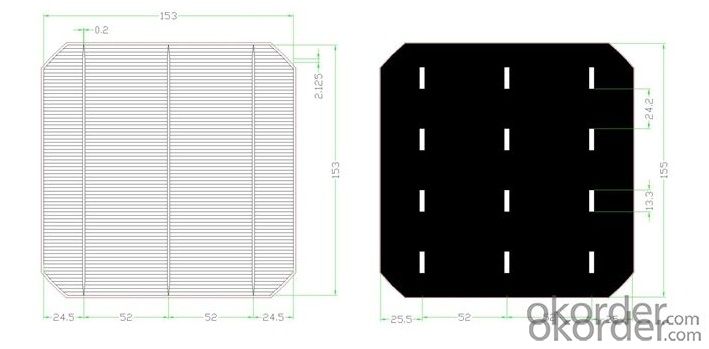

Monocrystalline Silicon Solar Cell/156mm Mono Solar Cell

Type:156M

Appearance:156×1565㎜±0.5mm;diagonal:R=100mm

Main fence wide:1.4-1.5mm back electrode wide:2-2.5mm

Fence line qty:90

Cell thickness:220um±20um

Eff(%) | 18.00- 18.10 | 18.10- 18.20 | 18.20- 18.30 | 18.30- 18.40 | 18.40- 18.50 | 18.50- 18.60 | 18.60- 18.70 | 18.70- 18.80 | 18.80- 18.90 | 18.9- 19.0 | 19.1- 19.1 | 19.1- 19.2 |

Pm(W) | 4.30 | 4.33 | 4.35 | 4.37 | 4.40 | 4.42 | 4.44 | 4.47 | 4.49 | 4.52 | 4.54 | 4.56 |

Isc(A) | 8.71 | 8.73 | 8.76 | 8.77 | 8.78 | 8.82 | 8.83 | 8.85 | 8.86 | 8.88 | 8.9 | 8.93 |

Im(A) | 8.19 | 8.21 | 8.24 | 8.26 | 8.30 | 8.33 | 8.35 | 8.39 | 8.42 | 8.45 | 8.47 | 8.51 |

Voc(V) | 0.630 | 0.631 | 0.632 | 0.633 | 0.634 | 0.634 | 0.635 | 0.636 | 0.637 | 0.637 | 0.638 | 0.64 |

Vm(V) | 0.527 | 0.528 | 0.529 | 0.531 | 0.531 | 0.532 | 0.534 | 0.534 | 0.535 | 0.536 | 0.537 | 0.538 |

FF(%) | 78.6 | 78.7 | 78.8 | 79.0 | 79.2 | 79.3 | 79.5 | 79.6 | 79.8 | 80 | 80 | 80 |

Picture show

Shipping

1. Shipment shall be made only after PAYMENT is received.

2. Please do inform us your DETAILED ADDRESS AND CONTACT INFOMATION before shipment.

3. Shipment shall be made in THREE WORKING DAYS.

2. Shipment shall be via EMS, DHL, Fedex,UPS etc.

- Q: Begged monocrystalline silicon rod is to use what tools and equipment to cut into silicon. What are the most commonly used methods. Loss big? Thank you

- Common cutting methods for diamond wire cutting and sand cutting

- Q: Are solar silicon wafers susceptible to cracking?

- Yes, solar silicon wafers are susceptible to cracking.

- Q: What is the global production capacity of solar silicon wafers?

- The global production capacity of solar silicon wafers is estimated to be around 120 GW (gigawatts) per year.

- Q: What is the market size for solar silicon wafers?

- The market size for solar silicon wafers is constantly evolving and expanding due to the growing demand for solar energy. As of 2021, it is estimated to be in the range of several billion dollars, with projections of further growth in the coming years.

- Q: How is a front contact applied to a solar silicon wafer?

- A front contact is typically applied to a solar silicon wafer through a process known as screen printing. In this process, a conductive paste containing metal particles is applied to the front surface of the wafer using a fine mesh screen. The paste is then dried and fired at high temperatures, causing the metal particles to fuse together and form a continuous conductive layer. This front contact acts as an electrode, allowing the collection and extraction of the generated electrical current from the solar cell.

- Q: What is the typical size of a solar silicon wafer?

- The typical size of a solar silicon wafer is 156mm x 156mm or 6 inches x 6 inches.

- Q: How is the reflectivity of a solar silicon wafer reduced?

- The reflectivity of a solar silicon wafer is reduced by applying an anti-reflective coating on its surface. This coating helps to minimize the amount of sunlight reflected off the wafer, allowing more light to be absorbed and converted into electricity.

- Q: Are solar silicon wafers affected by electromagnetic waves?

- Yes, solar silicon wafers are indeed affected by electromagnetic waves. Electromagnetic waves, such as those emitted by radio frequencies or microwaves, can interfere with the performance of solar silicon wafers. This interference can lead to a reduction in the efficiency of the solar cells or even disrupt their operation entirely. As a result, it is crucial to consider electromagnetic interference when designing and installing solar panels to ensure optimal performance and minimize any potential negative impacts.

- Q: What is the typical shelf life of a solar silicon wafer?

- The typical shelf life of a solar silicon wafer can vary depending on several factors such as storage conditions and handling. However, under proper storage conditions, a solar silicon wafer can have a shelf life of several years.

- Q: Are there any alternatives to solar silicon wafers?

- Yes, there are several alternatives to solar silicon wafers. Some of the alternatives include thin-film solar cells made from materials like cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and organic photovoltaic (OPV) cells. These alternatives have different advantages and disadvantages compared to silicon wafers, such as lower production costs, flexibility, and better performance in low-light conditions. However, silicon wafers still dominate the solar market due to their high efficiency and proven reliability.

Send your message to us

Industrial Silicon Wafer Solar Cells / 156mm Mono Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords