Hot Rolled Steel I-Beam in European Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

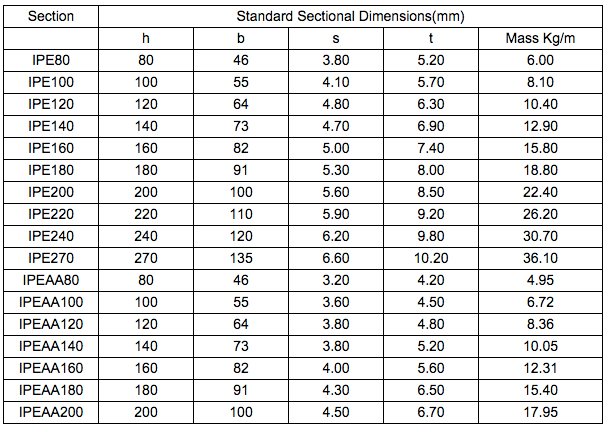

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

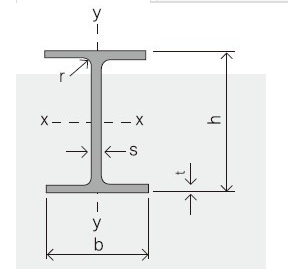

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

Q3:What's your payment terms ?

A3:Mostly,we collect the money by T/T and LC at sight . We also accept time LC at 90/120 days sigh

.

Images:

- Q: Can steel I-beams be customized or fabricated to specific project requirements?

- Yes, steel I-beams can be customized or fabricated to specific project requirements.

- Q: Can steel I-beams be used for overhead crane runways?

- Yes, steel I-beams can be used for overhead crane runways. Steel I-beams are commonly used in construction and are known for their strength and durability. They are specifically designed to bear heavy loads and provide structural support. When used for overhead crane runways, steel I-beams can provide a stable and sturdy foundation for the crane system. However, it is important to ensure that the I-beams are properly sized and installed to meet the specific requirements of the crane and the loads it will be carrying. Additionally, regular inspections and maintenance should be conducted to ensure the integrity of the I-beams over time.

- Q: Can steel I-beams be used for oil and gas refineries?

- Yes, steel I-beams can be used for oil and gas refineries. Steel I-beams are commonly used in the construction industry due to their high strength and durability. In oil and gas refineries, where heavy equipment and machinery are involved, steel I-beams provide the necessary support and stability required for the structures. They are used for various purposes such as supporting heavy loads, creating framework for platforms and walkways, and providing structural integrity to buildings and equipment. The versatility and structural properties of steel I-beams make them well-suited for the demanding conditions of oil and gas refineries. Additionally, steel is resistant to corrosion and can withstand high temperatures, making it an ideal choice for these industrial applications.

- Q: Can steel I-beams be used for pedestrian bridges?

- Yes, steel I-beams can be used for pedestrian bridges. They are often used in the construction of pedestrian bridges due to their strength, durability, and ability to support heavy loads.

- Q: How are steel I-beams measured?

- Steel I-beams are typically measured by their height, width, and weight per foot. The height refers to the vertical distance between the top and bottom flanges, while the width represents the horizontal distance between the flanges. The weight per foot indicates the mass of the beam per linear foot. These measurements help determine the structural properties and load-bearing capacity of the I-beam.

- Q: Can steel I-beams be used in agricultural buildings?

- Yes, steel I-beams can be used in agricultural buildings. Steel I-beams are commonly used in construction due to their strength and durability, making them a suitable choice for agricultural structures that require robust support for heavy loads and long spans. Additionally, steel is resistant to pests, fire, and rot, making it a practical material for agricultural buildings.

- Q: How do you calculate the shear deflection in a steel I-beam?

- In order to determine the shear deflection in a steel I-beam, it is necessary to take into account both the properties of the beam and the applied load. The shear deflection is a measure of the deformation or displacement that occurs perpendicular to the applied shear force. To calculate the shear deflection in a steel I-beam, the following step-by-step process can be followed: 1. Identify the properties of the steel I-beam: This includes knowing the moment of inertia (I), the cross-sectional area (A), the length (L), and the modulus of elasticity (E) of the steel. 2. Determine the magnitude of the applied shear force: This refers to the external force exerted on the beam that leads to its deformation. Typically denoted as V. 3. Compute the shear stress: The shear stress (τ) can be obtained by dividing the applied shear force by the cross-sectional area of the beam (τ = V / A). 4. Calculate the shear strain: The shear strain (γ) signifies the beam's deformation caused by the applied shear force. It can be computed by dividing the shear stress by the steel's modulus of elasticity (γ = τ / E). 5. Determine the shear deflection: The shear deflection (δ) corresponds to the beam's displacement perpendicular to the applied shear force. It can be calculated using the formula: δ = (V × L^3) / (3 × E × I). In this formula, V represents the applied shear force, L stands for the beam's length, E represents the steel's modulus of elasticity, and I represents the moment of inertia of the beam. By following these steps and utilizing the appropriate formulas, the shear deflection in a steel I-beam can be determined. It is important to note that these calculations assume certain simplifications, such as the beam being homogeneous and exhibiting linear elastic behavior. For more precise results, employing advanced finite element analysis software or consulting an engineer may be necessary.

- Q: How are steel I-beams measured and classified?

- Steel I-beams undergo measurement and classification based on their dimensions and properties. Typically, an I-beam's measurement encompasses height, flange width, web thickness, and flange thickness. Height refers to the vertical distance from the beam's top to bottom, while flange width represents the horizontal distance between the flanges' outer edges. Web thickness pertains to the width of the beam's central vertical section, and flange thickness denotes the thickness of the top and bottom horizontal sections. I-beams receive classification according to their size, shape, and strength. The American Institute of Steel Construction (AISC) provides a standardized system for I-beam classification, utilizing designations like S, HP, W, C, and MC. The S designation is for standard I-beams, with HP representing "wide flange" or "H-shaped" beams. W beams possess wider flanges than standard I-beams, while C beams have smaller flanges. MC beams, also called "channels," exhibit a C-shaped profile. Moreover, I-beam classification considers load-bearing capacity and bending strength. These factors are determined through calculation of the beam's moment of inertia and section modulus based on its dimensions. Structural engineers rely on these properties to select the appropriate I-beam for specific applications, ensuring it can support required loads and withstand bending or deflection. Apart from standard measurements and classifications, I-beams may have supplementary specifications like material grade and surface finish. Material grade signifies the steel's quality and strength, spanning from low-grade to high-strength alloys. Surface finish ranges from rough mill finish to painted or galvanized coatings, depending on desired appearance and corrosion resistance. Overall, the measurement and classification of steel I-beams involve evaluating dimensions, properties, load-bearing capacity, and strength. This information proves indispensable for engineers and architects in designing and constructing secure and efficient structures.

- Q: Can steel I-beams be used in the construction of theaters and performance venues?

- Yes, steel I-beams can be commonly used in the construction of theaters and performance venues. They provide strong structural support, allowing for larger and open spaces without obstructive columns. Steel I-beams are often used to create the framework for stages, catwalks, lighting rigs, and other crucial elements in these types of buildings.

- Q: Are steel I-beams prone to corrosion?

- Indeed, corrosion is a common issue with steel I-beams. Typically crafted from carbon steel, these I-beams are vulnerable to corrosion when exposed to moisture and oxygen. When the iron in the steel interacts with oxygen, it forms iron oxide, commonly referred to as rust. This rusting process weakens the I-beam's structural integrity and can result in significant damage if not addressed. To reduce the risk of corrosion, protective finishes like paint or galvanization are often applied to steel I-beams. These coatings create a barrier between the steel and the surrounding environment, preventing direct contact between the metal and moisture or oxygen. It is also vital to regularly inspect and maintain the I-beams to promptly identify any signs of corrosion and implement appropriate measures to prevent further harm. Despite these preventive measures, steel I-beams can still be susceptible to corrosion, particularly in harsh environments such as coastal areas with high salt levels in the air. Therefore, it is crucial to consider the environmental conditions when selecting the type of steel and protective coating for I-beams. This consideration will help minimize the risk of corrosion, ensuring the longevity and structural integrity of the I-beams.

Send your message to us

Hot Rolled Steel I-Beam in European Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords