High Quality Hot Rolled Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Steel H-beam

1. Standard: GB

2. Grade: Q235 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

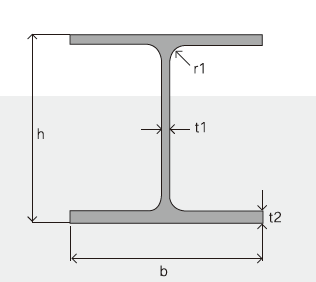

Category | model (height*width)/ (mm×mm) | Section size/mm | Cross-section area/cm2 | Theoretical Weight/(kg/m) | Moment of inertia/cm4 | radius/cm | Section modulus/cm3 | |||||||

H | B | t1 | t2 | r | Ix | Iy | ix | iy | Wx | Wy | ||||

HW | 100×100 | 100 | 100 | 6 | 8 | 8 | 21.59 | 16.9 | 386 | 134 | 4.23 | 2.49 | 77.1 | 26.7 |

125×125 | 125 | 125 | 6.5 | 9 | 8 | 30.00 | 23.6 | 843 | 293 | 5.30 | 3.13 | 135 | 46.9 | |

150×150 | 150 | 150 | 7 | 10 | 8 | 39.65 | 31.1 | 1620 | 563 | 6.39 | 3.77 | 216 | 75.1 | |

175×175 | 175 | 175 | 7.5 | 11 | 13 | 51.43 | 40.4 | 2918 | 983 | 7.53 | 4.37 | 334 | 112 | |

200×200 | 200 | 200 | 8 | 12 | 13 | 63.53 | 49.9 | 4717 | 1601 | 8.62 | 5.02 | 472 | 160 | |

200 | 204 | 12 | 12 | 13 | 71.53 | 56.2 | 4984 | 1701 | 8.35 | 4.88 | 498 | 167 | ||

250×250 | 244 | 252 | 11 | 11 | 13 | 81.31 | 63.8 | 8573 | 2937 | 10.27 | 6.01 | 703 | 233 | |

250 | 250 | 9 | 14 | 13 | 91.43 | 71.8 | 10689 | 3648 | 10.81 | 6.32 | 855 | 292 | ||

250 | 255 | 14 | 14 | 13 | 103.93 | 81.6 | 11340 | 3875 | 10.45 | 6.11 | 907 | 304 | ||

HM | 150×100 | 148 | 100 | 6 | 9 | 8 | 26.35 | 20.7 | 995.3 | 150.3 | 6.15 | 2.39 | 134.5 | 30.1 |

200×150 | 194 | 150 | 6 | 9 | 8 | 38.11 | 29.9 | 2586 | 506.6 | 8.24 | 3.65 | 266.6 | 67.6 | |

250×175 | 244 | 175 | 7 | 11 | 13 | 55.49 | 43.6 | 5908 | 983.5 | 10.32 | 4.21 | 484.3 | 112.4 | |

HN | 100×50 | 100 | 50 | 5 | 7 | 8 | 11.85 | 9.3 | 191.0 | 14.7 | 4.02 | 1.11 | 38.2 | 5.9 |

125×60 | 125 | 60 | 6 | 8 | 8 | 16.69 | 13.1 | 407.7 | 29.1 | 4.94 | 1.32 | 65.2 | 9.7 | |

150×75 | 150 | 75 | 5 | 7 | 8 | 17.85 | 14.0 | 645.7 | 49.4 | 6.01 | 1.66 | 86.1 | 13.2 | |

175×90 | 175 | 90 | 5 | 8 | 8 | 22.90 | 18.0 | 1174 | 97.4 | 7.16 | 2.06 | 134.2 | 21.6 | |

200×100 | 198 | 99 | 4.5 | 7 | 8 | 22.69 | 17.8 | 1484 | 113.4 | 8.09 | 2.24 | 149.9 | 22.9 | |

200 | 100 | 5.5 | 8 | 8 | 26.67 | 20.9 | 1753 | 133.7 | 8.11 | 2.24 | 175.3 | 26.7 | ||

250×125 | 248 | 124 | 5 | 8 | 8 | 31.99 | 25.1 | 3346 | 254.5 | 10.23 | 2.82 | 269.8 | 41.1 | |

250 | 125 | 6 | 9 | 8 | 36.97 | 29.0 | 3868 | 293.5 | 10.23 | 2.82 | 309.4 | 47.0 | ||

300×150 | 298 | 149 | 5.5 | 8 | 13 | 40.80 | 32.0 | 5911 | 441.7 | 12.04 | 3.29 | 396.7 | 59.3 | |

300 | 150 | 6.5 | 9 | 13 | 46.78 | 36.7 | 6829 | 507.2 | 12.08 | 3.29 | 455.3 | 67.6 | ||

350×175 | 346 | 174 | 6 | 9 | 13 | 52.45 | 41.2 | 10456 | 791.1 | 14.12 | 3.88 | 604.4 | 90.9 | |

350 | 175 | 7 | 11 | 13 | 62.91 | 49.4 | 12980 | 983.8 | 14.36 | 3.95 | 741.7 | 112.4 | ||

400×150 | 400 | 150 | 8 | 13 | 13 | 70.37 | 55.2 | 17906 | 733.2 | 15.95 | 3.23 | 895.3 | 97.8 | |

HT | 100×50 | 95 | 48 | 3.2 | 4.5 | 8 | 7.62 | 6.0 | 109.7 | 8.4 | 3.79 | 1.05 | 23.1 | 3.5 |

97 | 49 | 4 | 5.5 | 8 | 9.38 | 7.4 | 141.8 | 10.9 | 3.89 | 1.08 | 29.2 | 4.4 | ||

100×100 | 96 | 99 | 4.5 | 6 | 8 | 16.21 | 12.7 | 272.7 | 97.1 | 4.10 | 2.45 | 56.8 | 19.6 | |

125×60 | 118 | 58 | 3.2 | 4.5 | 8 | 9.26 | 7.3 | 202.4 | 14.7 | 4.68 | 1.26 | 34.3 | 5.1 | |

120 | 59 | 4 | 5.5 | 8 | 11.40 | 8.9 | 259.7 | 18.9 | 4.77 | 1.29 | 43.3 | 6.4 | ||

125×125 | 119 | 123 | 4.5 | 6 | 8 | 20.12 | 15.8 | 523.6 | 186.2 | 5.10 | 3.04 | 88.0 | 30.3 | |

150×75 | 145 | 73 | 3.2 | 4.5 | 8 | 11.47 | 9.0 | 383.2 | 29.3 | 5.78 | 1.60 | 52.9 | 8.0 | |

147 | 74 | 4 | 5.5 | 8 | 14.13 | 11.1 | 488.0 | 37.3 | 5.88 | 1.62 | 66.4 | 10.1 | ||

150×100 | 139 | 97 | 4.5 | 4.5 | 8 | 13.44 | 10.5 | 447.3 | 68.5 | 5.77 | 2.26 | 64.4 | 14.1 | |

142 | 99 | 4.5 | 6 | 8 | 18.28 | 14.3 | 632.7 | 97.2 | 5.88 | 2.31 | 89.1 | 19.6 | ||

150×150 | 144 | 148 | 5 | 7 | 8 | 27.77 | 21.8 | 1070 | 378.4 | 6.21 | 3.69 | 148.6 | 51.1 | |

147 | 149 | 6 | 8.5 | 8 | 33.68 | 26.4 | 1338 | 468.9 | 6.30 | 3.73 | 182.1 | 62.9 | ||

175×90 | 168 | 88 | 3.2 | 4.5 | 8 | 13.56 | 10.6 | 619.6 | 51.2 | 6.76 | 1.94 | 73.8 | 11.6 | |

171 | 89 | 4 | 6 | 8 | 17.59 | 13.8 | 852.1 | 70.6 | 6.96 | 2.00 | 99.7 | 15.9 | ||

175×175 | 167 | 173 | 5 | 7 | 13 | 33.32 | 26.2 | 1731 | 604.5 | 7.21 | 4.26 | 207.2 | 69.9 | |

172 | 175 | 6.5 | 9.5 | 13 | 44.65 | 35.0 | 2466 | 849.2 | 7.43 | 4.36 | 286.8 | 97.1 | ||

200×100 | 193 | 98 | 3.2 | 4.5 | 8 | 15.26 | 12.0 | 921.0 | 70.7 | 7.77 | 2.15 | 95.4 | 14.4 | |

196 | 99 | 4 | 6 | 8 | 19.79 | 15.5 | 1260 | 97.2 | 7.98 | 2.22 | 128.6 | 19.6 | ||

200×150 | 188 | 149 | 4.5 | 6 | 8 | 26.35 | 20.7 | 1669 | 331.0 | 7.96 | 3.54 | 177.6 | 44.4 | |

Usage & Applications of Hot Rolled Steel H-beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Steel H-beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Are Steel H-Beams resistant to termite or insect damage?

- Yes, Steel H-Beams are highly resistant to termite or insect damage. Unlike wood, steel does not provide a food source for termites or insects, making it an ideal material for structural components such as H-Beams.

- Q: Can Steel H-Beams be used in museum or gallery construction?

- Yes, Steel H-Beams can be used in museum or gallery construction. Steel H-Beams are commonly used in construction due to their strength and durability. They provide structural support and can be used to create large open spaces, allowing for versatile and flexible designs. Additionally, they can be easily fabricated and installed, making them suitable for various architectural styles and requirements.

- Q: Can steel H-beams be used for multi-story buildings?

- Indeed, multi-story buildings can utilize steel H-beams. These beams, also referred to as I-beams, are frequently employed in the field of construction owing to their robustness and capacity to bear loads. The purpose of these beams is to evenly distribute the weight of the building and offer structural reinforcement. Their unique shape enhances stability and resistance against bending or twisting forces. Steel H-beams are commonly employed in the construction of multi-story buildings due to their aptitude for supporting hefty loads and providing a sturdy framework. Additionally, steel is a resilient material that can withstand diverse weather conditions, rendering it a favored choice for high-rise construction.

- Q: Are Steel H-Beams suitable for historical or heritage preservation projects?

- Yes, Steel H-Beams can be suitable for historical or heritage preservation projects. Steel H-Beams offer structural strength, durability, and versatility, making them an ideal choice for restoring and preserving historical buildings or structures. Additionally, they can be fabricated to match the original design, ensuring the preservation of the architectural integrity. However, it is important to consider the specific requirements of each project and consult with preservation experts to ensure the appropriate use of materials.

- Q: How are steel H-beams manufactured?

- Steel H-beams are manufactured through a process called hot rolling, where molten steel is poured into molds and then passed through a series of rollers to shape it into the desired H-beam profile. The heat and pressure applied during hot rolling help to achieve the required strength and structural integrity of the beams. After the hot rolling process, the H-beams are further cooled, cut to the desired length, and undergo various quality checks before being ready for use in construction projects.

- Q: Can steel H-beams be used in industrial manufacturing facilities?

- Yes, steel H-beams are commonly used in industrial manufacturing facilities due to their high strength and load-bearing capacity. They are often used as structural support beams, providing stability and durability to the facility's infrastructure.

- Q: Are steel H-beams resistant to pests like termites?

- Steel H-beams possess a high level of resistance against pests such as termites. In contrast to wooden beams, which are prone to termite infestations, steel H-beams do not serve as a food source for termites nor create a suitable environment for their thriving. Termites primarily feed on cellulose, a substance present in wood. However, as steel is not composed of organic material, termites are not attracted to it. Furthermore, steel H-beams are impervious to moisture damage and decay, which are other factors that can attract and sustain termite colonies. Consequently, incorporating steel H-beams in construction markedly diminishes the risk of termite infestation and potential harm to the structure.

- Q: Can Steel H-Beams be used in modular or prefabricated construction?

- Modular or prefabricated construction can utilize Steel H-Beams effectively. These H-Beams are frequently employed in construction projects owing to their robustness, endurance, and versatility. They offer exceptional structural support and can endure substantial loads, making them highly suitable for modular or prefabricated construction that necessitates swift and efficient assembly. In these construction methods, Steel H-Beams are often used as columns, beams, or trusses, providing a sturdy and stable framework for the modular components. Moreover, their standardized sizes and uniform shape make them effortless to transport and assemble on-site, further augmenting the efficiency of modular or prefabricated construction. In conclusion, due to their strength, adaptability, and ease of installation, Steel H-Beams are widely favored in this type of construction.

- Q: Use H section steel to make the beam, the span of 8 meters, the floor slab, what's the minimum H steel? What's the model?

- Choose H250X100X4X6, and if there is no snow in the south, the web can be used. 220 is the ultimate limit

- Q: What are the maintenance requirements for steel H-beams?

- To maintain steel H-beams, it is crucial to regularly inspect them, clean them, and protect them from corrosion. Ensuring the structural integrity of the beams requires conducting frequent inspections. These inspections involve visually examining the beams for any signs of damage, such as cracks, rust, or structural deformities. If any issues are found, prompt action should be taken to prevent further deterioration. Cleaning the steel H-beams is also vital for maintaining their performance. Over time, the beams can accumulate dirt, dust, and other contaminants that can potentially affect their structural integrity. Cleaning can be accomplished using appropriate methods, such as pressure washing or using non-abrasive cleaning agents. It is important to avoid using abrasive materials or cleaning agents that could damage the steel surface. Furthermore, protecting the steel H-beams from corrosion is a critical aspect of their maintenance. Steel is prone to rust and corrosion when exposed to moisture and certain environmental conditions. To prevent corrosion, it is advisable to apply protective coatings, such as paint or galvanization, to the steel beams. These coatings act as a barrier, preventing moisture and other corrosive elements from reaching the steel surface. Moreover, if the steel H-beams are installed in environments with high humidity, corrosive chemicals, or extreme temperatures, additional measures may be required. These measures might include periodically reapplying protective coatings or implementing strategies to control environmental conditions, such as humidity control or temperature regulation. In conclusion, conducting regular inspections, cleaning the beams, and protecting them against corrosion are vital maintenance requirements for steel H-beams. Following these maintenance practices will help ensure the long-term durability and structural performance of the beams, while also preventing potential safety risks.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 230 Million |

| Main Markets | Mid East; Southeast Asia; Korea |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 500,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

High Quality Hot Rolled Steel H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords