Horizontal Split Case Stain Steel Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Horizontal Split Case Stain Steel Centrifugal Pump

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

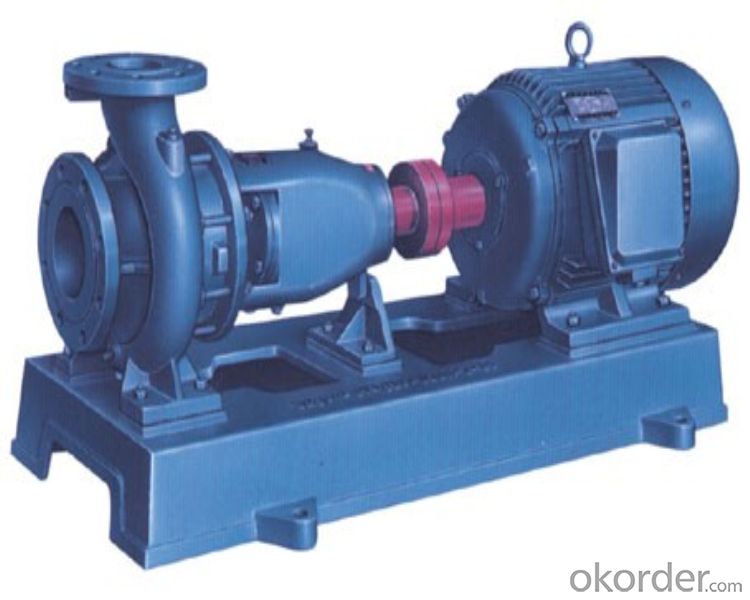

Product Parameters of Horizontal Split Case Stain Steel Centrifugal Pump

| Capacity: | 6.3~400m³/h |

| Head: | 5~125m |

| Speed: | 2900r/min and 1450r/min |

| Power of fitted motor: | 0.55~90kW |

| Inler diameter: | 50~200mm |

| The max working pressure: | 1.6MPa |

Application Range of Horizontal Split Case Stain Steel Centrifugal Pump

1.Suitable for environment protection, construction, fire fighting, chemical pharmacy, printing, dyeing, brewage, power plant, electroplate,

paper making, washing for mining and cooling for equipment.

2.Application as sprayer equipped with beam nozzle that turning water into little drop irrigation for farm, garden, etc.

3.It is suitable for clear water, sea water, acid or alkali chemical medium and slurry (viscosity≤100 centipoise, consistency of solid can not exceed 30% of total medium).

Horizontal Split Case Stain Steel Centrifugal Pump Features

1. Resistant to acid, alkali, wear and high temperature.

2. High mechanical strength, steady performance, good tightness.

3. Convenient operation and durable.

4. Be able to transport water that under the position it was installed. No need for filling liquid after the first time it was used.

Horizontal Split Case Stain Steel Centrifugal Pump Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

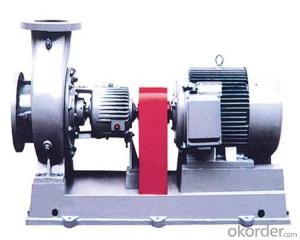

Pictures show

Why choose us

High Quality

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q: So I purchased this car last week. It ran great for three days until it started leaking water so much that it caused it to over heat. My uncle checked it out for me and said it was either the seal or the water pump. Yesterday we replaced the seal and still leaking water. So we now know it is the water pump. My uncle and every mechanic I know has turned down the job saying it is too much work. I even called two small shops yesterday and got turned down saying it was too much work. It is Sunday so most mechanics are closed. Can anyone give me an estimate on how much this will cost. The problem is everyone is saying that the pump is located inside the timing belt which is hard to put back after replacing the pump. Anyone ever have this repair done before or know a price range. I am a college student and need this car running asap and only got about $500 i can put into it. It is a V6 engine.Thanks

- 91 Plymouth Acclaim

- Q: Power went out of my house and we just had it restored, though now the water is no longer running. We called the people who installed our pump and they told us they would need to dig up the well which is going to cost $1500. However i remember a time before where this happened and all we needed to was reset the switch. Do you think these ppl are trying to get me for my money? Does anyone know if there is a less expensive way?

- What i don't understand is how they could know that they needed to dig up the well BEFORE they got there to troubleshoot it. They need to know circuits aren't tripped which easily could have happened if the well was running when the power went out, or if the power came back on......and the well pump just ran and ran without prime ( Without water running through it) So I would check the breakers or fuses first.......and call a second opinion, it doesn't seem right for them to quote you over the phone like that. Could be as simple as the well lost its prime.

- Q: Where can I get supplies to build water pumps, for decoration.Thank you.

- Home Depot, Lowes, Michael's craft stores, waterfall and water feature stores, Target, WalMart and sometimes Big Lots. I've also found supplies to build decorative water pumps at my local nurseries, Green Thumb and Armstrong.

- Q: Fire hydrant and fire pump adapter difference

- 1, fire hydrant is generally divided into three types, one is indoor, one is outside, is a municipal, the three has two basic purposes, which is directly connected to the fire hose or fire-fighting water, is the scene of the fire truck with water.2, fire pump adapter from the purpose, for fire hydrant system, automatic spray (spray, Yu Lin) system, divided up from the form, have walls, underground, ground type, its basic purpose is, after the fire, if the fire hydrant system (for example network system) when the water pressure is insufficient or anhydrous (water pump system damage and other reasons), through the pump adapter, the fire water supply to the system or booster.

- Q: We had to have our well pump replaced yesterday, how long before the well settles down, and the water tastes like it used to?The company who replaced the pump told us when changing a pump it disturbs the well, and it would take time for everything to settle back into place. Thank you in advance for any and all suggestions.

- There are several things that contribute to settling down. If the pump was the only thing changed and not the depth it will no doubt take a couple of weeks. How far off the bottom of the vein of water does the pipe begin. Another factor is the type of soil. Sandy soil will generally run clear in a shorter period of time. If you have clay soil it will take longer. Another factor is the time of year. Given the fact that the water tables themselves change during the course of the year and depends on where you live. For example, If you've lived there for a few years you've probably noticed that you get more rust in your water in January and August. A not so good scenario would be that the water vein is changing or diminishing and that's why the pump went out in the first place. But, that is something the well people should have checked for. I would find out from them how deep the vein is and how far off bottom you are. That's something you should know anyway. Many if not all States require this information to be given to them and is recorded when a new well is bug. You can probably access the information on-line at your States website. However, I would still ask the well people for the information in case the information is not required by your state. This way they would have a better recollection of any particulars.

- Q: There are heard buzzing, but can not move and no death card, is not a bad capacitor, how much is the direct standard capacitance it?

- The motor is sure of electricity, isn't it? Is there a low voltage or broken phase (three-phase motor), these cases will cause the motor does not turn, or low speed (easy to block), so should be measured with a universal meter. Maybe the boot capacitor is broken. Or smell the smell of burning. It might be a short circuit between the motor windings. (bearings should be hard to break). Look for repairs if you suggest. You may not be good. Oh, capacitor. You can measure good and bad with a universal watch. If the capacitor is replaced, it is better to choose the same capacitor as the original configuration parameter.

- Q: can a water pump pumping out air instead of water?

- It depends on the type of pump.Some pumps can others will burn out. Carpet cleaner type suction will happily cope with both air and water,old fashioned hand operated lift pumps do as well. Bilge pumps etc do not like running dry and will have to be reprimed to suck water if the get an air lock.

- Q: I took my 04 Grand Prix to the mechanic for a coolant change. My car had never drip coolant until after the coolant change . I took my car today to the same mechanic and he told me that the problem was the water pump and wants to charge me 70 dollars. Could changing the coolant affect the water pump. Or did the mechanic damaged the water pump on purpose.

- I will try to put this simply. It is very serious. Water cools your engine and without the pump to circulate it, your engine will overheat and very quickly damage itself. Even if you add water constantly, it is not being circulated, your engine will overheat and the new water you will put in will probably instantly boil and rush up into your face. My advice. Don't drive it until you can get it fixed. Sorry, I know this isn't what you wanted to hear, but I am concerned for your safety and I don't want you to wreck your engine and you will if you keep driving it. The damage you can do is like this. The engine overheats and seizes up. This means that the engine parts, pistons and rings have expanded beyond design limits. They break inside and wreak havoc. The crankshaft and big end bearings can seize also. If all this happens, you are looking at a reconditioned engine. Fix your pump. It's cheaper

- Q: I just replaced my water pump.fixed.. A week later I've been noticing he might of over filled it because.were the coolant goes.steam comes.out.the little.while plus water.. And.before.I.started my.car I noticed.it was all empty now and my.engine sounds like a mini diesel when it runs.. What's the deal? And I.already filled it up with coolant again

- if it is low you still have a problem

- Q: Any ideas on where and what type of water pump I should use for my 29 Gallon BioCube tank? It seems that the water pump is very loud and is not working the way it should. There are bubbles shooting the aquarium and I have tried everything to fix it. I am thinking of replacing the water pump all together. Any ideas on brands that would be compatible? Anyone else tried this? Please help...

- ok before replacing have you cleaned the inside, and if there are air bubbles comming out it is because it is running dry. Basically all biocubes do this, the filter pad is slowing down the water too much, so either rince it well or replace it. Also i would wash out the blue sponge right before the pump as that can hold alot of dirt as well. Then if not add more water. But if you want to replace the pump, try via aqua water pumps. they tend to be the best. owner of the BC 29 and BC 14

Send your message to us

Horizontal Split Case Stain Steel Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords