High Pressure Boiler Feed Horizontal Multistage Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pressure Boiler Feed Multistage Water Pump

1.Structure of High Pressure Boiler Feed Multistage Water Pump Description

The high presuure boiler feed multistage water pump is a horizontal multistage centrifugal pump and suitable for transporting pure water,both ends of it are supported,the casing portion is a senctional form,it is connected and actuated by motor via a resilient clutch.From the driven direction,the pump rotated direction is clockwise.It is suitable for high and medium/low pressure hot clean water.

2.Main Features of High Pressure Boiler Feed Multistage Water Pump

• High Effiency

• Perfect Performance

•Low noise

•Long life, OEM and ODM are welcomed.

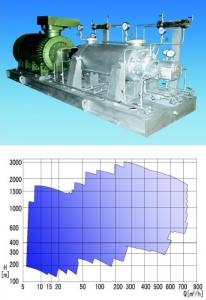

3.High Pressure Boiler Feed Multistage Water Pump Images

4.High Pressure Boiler Feed Multistage Water Pump Specification

Material |

Cast iron and as customer's request |

Temperature |

Less than 150°C |

Flow rate | 3.75-300m3/h |

Head | 75-1000m |

Medium temperature | 0 ~170°C |

Operation pressure | ≤40 bars |

5.FAQ

①What is the applications?

Power Station,Industry Water Supply

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: What does the temperature range of the pump mean?

- Not be too cold or hot water, will be frozen.

- Q: Our water pump was really warm/hot to the touch, our hot water was more warm than hot, and wouldnt heat up enough to get hot, and it wouldn't turn off. (like when it starts up when you turn on the water,it just kept going,and wouldn't stop) so, because it was hot, and going constantly, we didn't want it to explode, or burn out, so we turned it off, and now I'm hoping that when we turn it back on after it cools, that it'll go back to turning on/off intermittently, instead of constantly. So, after it cools down, will it go back to normal, instead of just constantly going??!?

- I assume you have a water well pump. The experience I have had, is it will come back on once the thermal safety switch cools down. However, I think you still have work here to do because each time this happens, you are shortening the life of your pump. First you need to determine why it ran hot to begin with. Could be lots of reasons, but just to name a few. -Is your water tank in good shape, with the correct air pressure? -Is the tank waterlogged, too old or leaking? -Any leaks in the service in or to the house? -Is your contact switch working properly, clean contacts, good wire, good connections, breaker etc.? -Is there water running somewhere your not aware of? -Last but not least, the check valve and foot valve leading to the well could also be defective. Just my opinion, I hope this helps to get you thinking. Good luck; flip;

- Q: 1.5KW water pump caliber is 40, what is the flow rate?

- General 40 caliber flow is 6.3 cubic meters, two pole motor lift about 32 meters.The so-called flow, refers to the unit of time through the closed pipeline or open channel effective cross-section of the fluid volume, also known as instantaneous flow. When the volume of fluid is expressed in volume, it is called volume flow. When the mass of fluid is expressed in mass, it is called mass flow.

- Q: I am having water shortage problems and wonder if there is more I can do to maintain the health of my pump motor , pressure switch , and diaphram tank , if I run one outlet in or out of house , it only takes another spigot being used or a toilet flush to cause the system to run dry .I then have to reprime pump to have water or pump will run dry until it overheats ,

- The okorder /

- Q: The meter on my dash was reading low even after driving for 20 minutes on a sunny day. Then all of a sudden it jumped over the 270 mark. I have a relatively new thermostat could my water pump have gone bad? I did not see any leaking coolant or anything under the vehicle.

- It sounds like the thermostat was stuck open from the last drive cycle, and thats why your car wouldn't warm up, then it sounds like (somehow) it is now stuck closed. The only way to be sure is to feel for any large differences in temperature before and after the thermostat to see if its stuck.

- Q: Please specify the reason, the more detailed the better, the head is the pump 1N fluid on the work done, when the flow rate increases, the shaft power increases, but it does not necessarily have to do with the head of the relationship

- When the power increases to a certain extent, can not be increased, so when the flow increases, the head can only be reduced

- Q: Submersible pump and self-priming pump which is easy to use?

- Dive into the water and leave alone

- Q: i have a 1996 infiniti i30t and its leaking from underneath the car so i took it in to get it diagnosed and they said i need a new water pump and they are trying to charge me 500 dollers and if i need a new timing belt i have to pay a 1000 dollers. is there a cheaper way i can fix my car. it started to over heat today and this sucks cause its my only car my parents wont buy me a new car so im stuck with this stupid old car and i have to pay for it they wont help me. can someone help me?

- I don't know how hard it is to change the water pump on this car, but do know some are real hard. I believe you are a female by your other question and because of that they are trying to blow you smoke. $500 to change the water pump is very high and another $500 for a timing belt is just to much. To replace the timing belt at that point most of the hard work is already finished, Take it someplace for an estimate. Better yet have a male, Dad, Uncle, BF take it in. This is no excuse, but a lot of places will charge a female 25 to 50% more and that not right. By the way, if you get the job done for a lot more reasonable price... guess whose nose would get the bill shoved under and I'd probably tell them what a jerk they are and every one else, just cost them as much business as possible.

- Q: Earlier today I was driving and my car shut off at a stop sign. I got it to start again and it shut off at the next stop sign, so after a few minutes I got it to start again and immediately pulled over as there was a small amount of smoke coming from under my hood. The temp gauge didn't say it was overheating, but I think it mightve been stuck, because that had to be what happened. After sitting there for a while it started and stayed that way for a while, I let the engine run. I drove it to the gas station and put some coolant directly in the radiator and the resevoir, and almost all of it leaked right out. I started to drive it home and had to pull over about 6 times to let it cool down because it kept overheating( temp gauge showed it this time). I think its the water pump that is leaking, but I know very little about cars, and was wondering if it could be anything else? Also, the heater wasn't working in the car today at all.

- If it's leaking from the water pump, you may as well do the timing belt, idle and tension pulleys too since they have to come off to do the pump. That pump is visible, you should be able to see the coolant dripping from under the belt drive pulley.

- Q: I would like a website that has pictures but any info would be helpful...

- if you have problem with overheating you have to upgrade your radiator and upgrade your fans too installing an external waterpump you have to install it on your passenger side like many drag cars have

Send your message to us

High Pressure Boiler Feed Horizontal Multistage Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords