First-class Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

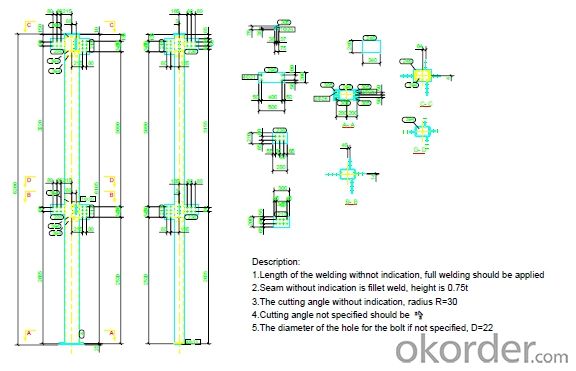

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: How are steel structures inspected and maintained?

- To ensure the stability, durability, and safety of steel structures, a systematic process of inspection and maintenance is implemented. Throughout the lifespan of the structure, regular inspections are conducted at various stages, including during construction and after completion. The inspections primarily consist of visual examinations aimed at identifying signs of corrosion, cracking, or other damages. Following this, more detailed assessments are carried out, which may involve non-destructive testing techniques like ultrasonic testing, magnetic particle testing, or radiography. These methods help uncover any hidden defects or weaknesses in the steel components. The maintenance of steel structures is of utmost importance to prevent deterioration and ensure long-term performance. Routine activities such as cleaning, painting, and lubrication are performed to safeguard against corrosion. Additionally, the condition of structural elements is continuously monitored, and any identified issues are promptly addressed. Apart from regular maintenance, periodic structural assessments are conducted to evaluate the load-carrying capacity of steel structures. This is particularly crucial for structures exposed to heavy loads or harsh environmental conditions. Structural assessments typically encompass a combination of visual inspections, material testing, and computer simulations to analyze the behavior of the structure under different loads. In summary, a comprehensive approach is necessary for the inspection and maintenance of steel structures to identify and resolve potential issues. By implementing a proactive maintenance regimen, steel structures can be maintained in optimal condition, ensuring their safety and longevity.

- Q: How are steel structures tested for strength and durability?

- Steel structures are tested for strength and durability through various methods such as non-destructive testing, destructive testing, and simulation analysis. Non-destructive testing techniques include ultrasonic testing, magnetic particle inspection, and radiographic testing, which help identify any defects or weaknesses in the structure without causing damage. Destructive testing involves subjecting samples of the steel to extreme conditions, such as tension, compression, or impact, to determine their ultimate strength and behavior under different loads. Simulation analysis, on the other hand, uses computer-aided techniques to model and predict the performance of steel structures under various conditions. These comprehensive testing methods ensure that steel structures meet the necessary safety standards and can withstand the expected loads and environmental conditions they will face.

- Q: How are steel structures used in automotive manufacturing plants?

- Steel structures are widely used in automotive manufacturing plants for various purposes. One of the key applications of steel structures in automotive manufacturing plants is in the construction of the factory buildings and production facilities. Steel, being a versatile and durable material, provides a strong and stable framework for these structures, ensuring the safety and stability of the entire facility. Steel structures are also used in the assembly lines and production equipment of automotive manufacturing plants. These structures provide a solid foundation and support for the heavy machinery and equipment used in the manufacturing process. The high load-bearing capacity of steel allows for the efficient and smooth operation of these machines, contributing to the overall productivity and efficiency of the plant. Moreover, steel structures are also utilized in the storage and logistics areas of automotive manufacturing plants. Steel warehouses and storage facilities are commonly used to store raw materials, components, and finished products. The strength and durability of steel structures ensure the protection of these valuable assets from environmental factors such as weather and theft. In addition, steel structures are used in the construction of maintenance and repair facilities within automotive manufacturing plants. These structures provide the necessary infrastructure for the maintenance and servicing of vehicles and equipment, ensuring that they remain in optimal condition. Overall, steel structures play a crucial role in automotive manufacturing plants by providing the necessary infrastructure and support for various operations. From the construction of buildings and production facilities to the assembly lines and storage areas, steel structures offer strength, durability, and efficiency, making them an essential component in the automotive manufacturing industry.

- Q: What are the different types of steel stairs in a structure?

- There are several types of steel stairs commonly used in structures, including straight stairs, spiral stairs, and cantilever stairs. Straight stairs are the most basic and common type, consisting of a straight flight of steps. Spiral stairs are compact and provide a space-saving solution, wrapping around a central pole. Cantilever stairs are a more architectural choice, featuring floating steps supported by a single stringer or hidden structure. Other variations include L-shaped and U-shaped stairs, which are designed to fit specific structural and spatial requirements.

- Q: What are the key considerations in the design of steel structures for educational facilities?

- The key considerations in the design of steel structures for educational facilities include factors such as safety, functionality, flexibility, durability, and sustainability. Safety is paramount, with the design needing to meet all relevant building codes and regulations to ensure the protection of students, staff, and visitors. Functionality is crucial, as the design should accommodate various educational activities, from classrooms to laboratories, libraries, and recreational spaces. Flexibility is also important to allow for future expansion or changes in the educational programs. Durability is a key consideration to ensure the longevity of the structure and minimize maintenance costs. Lastly, sustainability plays a significant role in the design, with a focus on energy efficiency, use of sustainable materials, and incorporation of green technologies to minimize the environmental impact of the facility.

- Q: How are steel structures used in chemical and pharmaceutical plants?

- Steel structures are widely used in chemical and pharmaceutical plants due to their exceptional strength, durability, and resistance to corrosion. These structures provide a robust framework for housing various equipment, storage tanks, and piping systems involved in chemical and pharmaceutical processes. Additionally, steel structures are crucial for supporting heavy machinery, ensuring the safety and stability of the overall plant infrastructure.

- Q: What are the considerations for designing steel structures for vibration control?

- Considerations for designing steel structures for vibration control include: 1. Structural dynamics: Understanding the dynamic behavior of the structure is crucial to identify potential vibration issues and design appropriate mitigation measures. 2. Material selection: Choosing the right type and quality of steel is important to ensure the structure can withstand vibrations and dampen them effectively. 3. Structural stiffness: Increasing the stiffness of the structure can reduce its susceptibility to vibrations. This can be achieved through appropriate design and reinforcement. 4. Damping techniques: Implementing damping techniques such as adding tuned mass dampers or using energy dissipation devices can help absorb and dissipate vibrations, reducing their impact on the structure. 5. Foundation design: Proper foundation design is essential to minimize the transmission of vibrations from the ground to the structure. This may involve using vibration isolation techniques or selecting appropriate foundation materials. 6. Environmental factors: Considering the potential sources of vibrations, such as nearby machinery, traffic, or earthquakes, is important to design the structure accordingly and incorporate suitable measures for vibration control. 7. Compliance with regulations: Adhering to relevant building codes and standards for vibration control is crucial to ensure the safety and performance of the structure. By carefully addressing these considerations, engineers can design steel structures that effectively control vibrations, improving their durability, occupant comfort, and overall performance.

- Q: What are the considerations for designing steel structures in coastal areas?

- Careful consideration is necessary when designing steel structures in coastal areas due to the distinct environmental conditions present in these locations. Several key factors need to be taken into account: 1. Corrosion resistance: The high levels of saltwater and humidity in coastal areas can lead to accelerated corrosion of steel structures. To ensure the longevity and structural integrity of the building, it is essential to choose corrosion-resistant materials like stainless steel or galvanized steel. 2. Wind loads: Coastal areas are often prone to strong winds, especially during storms or hurricanes. The design of steel structures should consider the wind loads and ensure that the building can withstand these forces. This involves analyzing wind speed, direction, and duration to determine the appropriate structural design and connection details. 3. Wave loads: Coastal areas also experience wave action, particularly in regions with high tidal ranges or storm surges. The design of steel structures needs to account for the impact of waves and ensure that the building can endure these dynamic loads. This may involve incorporating additional reinforcement, such as bracing or diaphragms, to resist the forces generated by the waves. 4. Coastal erosion: Coastal areas are vulnerable to erosion, which can affect the stability of the land on which the steel structure is built. It is important to assess the potential for erosion and implement suitable measures to mitigate its impact. This may involve designing appropriate foundation systems, such as deep piles or erosion control structures, to ensure the stability of the structure over time. 5. Seismic considerations: Certain coastal areas are located in seismically active regions where earthquakes can occur. The design of steel structures in these areas must take into account the seismic forces and ensure that the building can withstand ground shaking. This may involve incorporating seismic design principles, such as ductility and energy dissipation, into the structural system. 6. Maintenance and inspection: Regular maintenance and inspection of steel structures are crucial in the harsh coastal environment. This includes periodic cleaning, painting, and corrosion protection to prevent deterioration. Additionally, inspections should be conducted to identify any signs of corrosion, structural damage, or degradation that may require repairs or reinforcement. In conclusion, a thorough understanding of the unique challenges posed by the coastal environment is essential when designing steel structures in coastal areas. By considering factors such as corrosion resistance, wind and wave loads, coastal erosion, seismic considerations, and maintenance, engineers can ensure the durability and safety of steel structures in these locations.

- Q: How are steel structures designed for efficient use of natural resources?

- Steel structures are designed for efficient use of natural resources through various measures. Firstly, the design process focuses on using the optimal amount of steel, minimizing waste and ensuring that the structure is lightweight yet strong enough to withstand the intended loads. Additionally, the use of advanced computer-aided design (CAD) software helps to optimize the design, resulting in less material consumption. Furthermore, steel structures are often designed with the ability to be dismantled and reused, reducing the demand for new materials. Finally, steel is a highly recyclable material, and the design of steel structures often incorporates the use of recycled steel, further reducing the need for virgin resources.

- Q: What are the factors to consider when designing steel structures for sports facilities?

- When it comes to designing steel structures for sports facilities, there are several key factors that must be taken into account. First and foremost, it is imperative to consider the unique requirements of the sports facility. Each sport has its own set of demands and regulations, so the design must be customized accordingly. For instance, the structural needs of a basketball arena will differ from those of a soccer stadium. The anticipated capacity and usage of the sports facility must also be factored into the design. The structure must be able to support the weight of the spectators, as well as any additional equipment like lighting or scoreboards. The design should also allow for flexibility in terms of accommodating different seating arrangements or event configurations. The location and climate of the sports facility are also important considerations. The design must account for local weather conditions, including wind and snow loads. The steel structure must be able to withstand these forces and ensure the safety of both spectators and athletes. Another important factor to consider is the maintenance and durability of the steel structure. Sports facilities experience heavy usage and wear, so it is crucial to select materials and a design that can withstand this. Regular inspections and maintenance should also be planned to ensure the longevity of the structure. Furthermore, the aesthetics and branding of the sports facility should not be overlooked. The design should align with the identity and purpose of the facility, whether it is a professional stadium or a community sports center. The use of steel in the design can provide opportunities for unique architectural features and visual appeal. Lastly, the budget and timeline for the project must be taken into consideration. Steel structures offer advantages in terms of cost-effectiveness and construction speed. However, it is essential to collaborate with experienced professionals who can provide accurate cost estimates and ensure the project is completed on time and within budget. To conclude, careful consideration of the specific requirements, capacity, location, maintenance, aesthetics, and budget is necessary when designing steel structures for sports facilities. By addressing these factors, a well-designed and functional sports facility can be created, ensuring the safety and enjoyment of athletes and spectators alike.

Send your message to us

First-class Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords