Half Round Aluminum Extrusion Profiles - Aluminum Sheet and Cold Rolled Plate Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

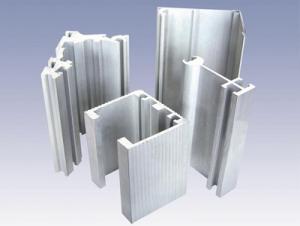

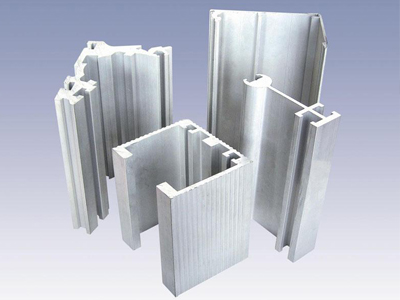

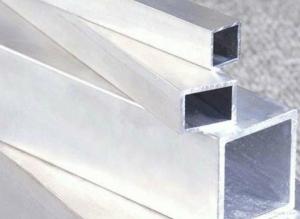

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

1100 grade and other else grades,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: You know, aluminum radiator, why should aluminum do?

- The biggest difference of aluminum radiator is that it has good corrosion resistance. Is due to the use of aluminum, it has the characteristics of corrosion resistance, because after aluminum in contact with oxygen, the aluminum surface to form a layer of oxide film, this layer of film to corrosion effect on the corrosion of an object. So, it's very good corrosion resistance.

- Q: This question asks for methods to avoid corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion on aluminum profiles during installation, follow these steps: Use high-quality aluminum that has a protective oxide layer. Ensure the installation environment is dry and clean. Avoid contact with corrosive substances like acids or alkalis. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Use stainless steel or corrosion-resistant fasteners. Regularly inspect and clean the profiles to remove any dirt or debris that could lead to corrosion. Proper installation techniques and maintenance can significantly reduce the risk of corrosion on aluminum profiles.</p>

- Q: Are aluminum profiles suitable for the furniture industry?

- Yes, aluminum profiles are highly suitable for the furniture industry. Aluminum is a versatile and durable material that offers numerous benefits for furniture manufacturing. Firstly, aluminum profiles are lightweight, making them easy to handle and transport, especially for bulky furniture items. This feature not only reduces transportation costs but also makes the furniture more user-friendly during installation and rearrangement. Secondly, aluminum is highly resistant to corrosion, ensuring that furniture made with aluminum profiles will withstand harsh weather conditions and remain durable over time. This makes it suitable for both indoor and outdoor furniture applications. Another advantage of aluminum profiles is their design flexibility. Aluminum can be easily extruded into various shapes and sizes, allowing for endless design possibilities. This versatility facilitates the creation of customized furniture pieces to meet specific client requirements. Aluminum profiles also offer excellent strength-to-weight ratio, making furniture made with aluminum sturdy and long-lasting. This feature is particularly beneficial for items that undergo regular use, such as chairs and tables. Furthermore, aluminum is a sustainable material as it is 100% recyclable. This aligns with the growing demand for environmentally-friendly furniture options. Manufacturers can easily recycle aluminum profiles at the end of their lifecycle and use the recycled material to create new furniture items, reducing waste and contributing to a circular economy. Overall, the unique properties of aluminum profiles make them highly suitable for the furniture industry. Their lightweight nature, corrosion resistance, design flexibility, strength, and recyclability all contribute to creating high-quality and sustainable furniture products.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or walls within a building.

- <p>Yes, aluminum profiles can be used for interior partitions or walls. They are lightweight, durable, and offer excellent resistance to corrosion. Aluminum profiles are easy to install and can be used in various configurations, making them suitable for both residential and commercial spaces. They also provide good thermal insulation and can be combined with other materials like glass or fabric for aesthetic and functional purposes.</p>

- Q: What are the different surface protection methods for aluminum profiles?

- There are several surface protection methods for aluminum profiles, including anodizing, powder coating, painting, and mechanical finishes. Anodizing is a popular method that creates a protective oxide layer on the surface, providing corrosion resistance and enhancing the appearance. Powder coating involves applying a dry powder onto the profile, which is then cured to create a durable and decorative finish. Painting is another option, where a liquid paint is applied and cured to protect the surface. Mechanical finishes involve processes like brushing or polishing to achieve a desired texture or appearance while still protecting the aluminum profile.

- Q: Can aluminum profiles be used for access control systems?

- Access control systems can utilize aluminum profiles, which are a versatile and durable material commonly used in construction and various industries. Aluminum offers an excellent strength-to-weight ratio and corrosion resistance, making it ideal for doors, frames, and enclosures. These profiles can easily accommodate locks, hinges, control panels, and readers. The lightweight nature of aluminum allows for easy installation and maintenance. Additionally, different coatings can be applied to enhance appearance and protect against harsh conditions. Customization is also possible, as aluminum profiles can be cut, drilled, and assembled to fit specific design requirements. Overall, aluminum profiles are a reliable and practical choice for securing access points.

- Q: The subject is aluminum bearing in what u ~ on both sides of the track?? How can the track be fitted into this slot? Both sides secure 50Mechanical expert answers!The subject is aluminum bearing in what u ~ on both sides of the track?? How can the track be fitted into this slot? How can the seat of fixed motor on both sides be connected with the section bar?

- The bearings are mounted on type U rails, which are specially made on the market. The rails and profiles are integral, not mounted.

- Q: This question asks about the impact of aluminum profiles on the sound insulation properties of a building.

- <p>Aluminum profiles can significantly affect the sound insulation of a building. They are often used in construction for their strength and lightweight properties. However, aluminum is a good conductor of sound, which can lead to sound transmission through the building structure. To enhance sound insulation, aluminum profiles are often combined with soundproofing materials such as acoustic foam or rubber seals. These materials help to absorb or block sound waves, reducing noise transmission. Additionally, the design and installation of aluminum profiles can also impact sound insulation; proper sealing and insulation techniques are crucial to minimize sound leakage.</p>

- Q: What are the various standards and regulations governing the use of aluminum profiles in construction?

- <p>Aluminum profiles in construction are governed by a variety of standards and regulations that ensure their quality, safety, and performance. These include ISO standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. National standards like ASTM B221 in the USA and EN 755 in Europe specify mechanical properties and chemical composition. Building codes such as the International Building Code (IBC) and Eurocode 9 also provide guidelines for the use of aluminum in construction. Additionally, there are specific regulations for fire resistance, sustainability, and environmental impact, like the European CE marking for construction products. Compliance with these standards is crucial for manufacturers and builders to ensure the reliability and safety of aluminum profiles used in construction projects.</p>

- Q: What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- 5 specific gravity density: under the same volume conditions, magnesium alloy is lighter than aluminum alloy, which is the advantage of magnesium alloy.6 modulus of elasticity: the frame made of magnesium alloy is more rigid than aluminum alloy frame, and the frame made of the same thickness and caliber can absorb more trampling force when riding, which will influence riding efficiency.

Send your message to us

Half Round Aluminum Extrusion Profiles - Aluminum Sheet and Cold Rolled Plate Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords