Aluminum Sheets for Siding - Aluminum Sheet and Cold Rolled Plate with Best Price

- Loading Port:

- Shanghai

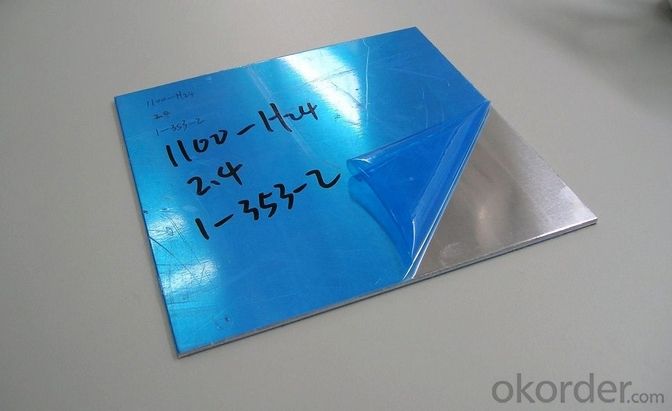

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

hot rolled and cold drawn aluminum plate are both widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105,8011, etc.

The temper is include H14, H22, H24,O,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1250mm*2500mm,1219mm*2438mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

what is the thickness range?

---normally the thickness range is from 0.2mm to 10mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

---Normally it is around 5 tons/each size.

Where are your clients from?

---Normally it is from Japan, USA, Canada, Turkey, Vietnam,HongKong, etc.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,aluminum casting coil, etc.

- Q: Are aluminum sheets fire-resistant?

- Aluminum sheets are not inherently fire-resistant, but they do have properties that make them more fire-resistant compared to other materials. Aluminum has a high melting point of 1220°F (660°C), which means it will not ignite or burn easily under normal conditions. Additionally, aluminum has a low ignition temperature and does not release flammable gases when heated. When exposed to fire, aluminum sheets form a protective oxide layer that acts as a barrier, preventing further combustion and slowing down the spread of flames. This oxide layer also helps to insulate the aluminum from the heat, reducing the risk of structural failure. However, it is important to note that while aluminum sheets have better fire resistance than materials like wood or plastic, they can still be damaged or deformed by intense heat. Therefore, it is crucial to consider other fire safety measures, such as using fire-resistant coatings or implementing fire suppression systems, in order to ensure maximum protection against fire hazards.

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 2, fluorocarbon spraying is a kind of electrostatic spraying, and liquid spraying methods, called fluorocarbon spraying called curium oil, Hongkong. Belonging to high-grade spraying, higher prices, has long been applied in foreign countries.

- Q: 1mm the aluminum plate is pulled to the height of 45mm. Can I pull it out at 1? How much space should I put in?

- How much clearance does aluminum plate stretch?The clearance value of the stretched aluminum plate is =1.3~1.4t (first stretch), 1.15~1.2t (second times stretch), and 1.1t (last stretch). The tensile properties of aluminum sheets are inferior to those of low carbon steel, and they are easily broken when stretched. The tensile height 45mm depends on the diameter of the drawing piece.A cylindrical part of a large cross-sectional area from a material to a small cross section is called a tensile coefficient. That is, the ratio of the cross-sectional area to the cross-sectional area before stretching, i.e., m=A0/An-1. For cylindrical parts, m1=d1/D0, the coefficient of the first stretch can be around 0.5, i.e., the diameter after the first stretch is 1/2 of the blank diameter before the drawing. In the future, the tensile coefficients are usually around 0.7~0.8. The calculation of drawing blank, roughly calculate the blank size according to the principle of equal area of the blank before and after the drawing.

- Q: What is the thermal conductivity of aluminum sheets?

- The thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin.

- Q: Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- You should set this project aside. Ignore my advice? You're on track for a Darwin Award. You win!

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- No. Copper metal will not reduce aluminum ions to aluminum metal. We can observe that copper is below aluminum in the activity series, which indicates that the Cu + Al3+ reaction is nonspontaneous. The other way round will work, sort-of. Aluminum metal will reduce copper ions. But it takes freshly prepared aluminum metal. Aluminum metal passivates, that is, it reacts with oxygen to form an Al2O3 layer on the surface of the metal. The presence of chloride ion will help provide a clean Al surface.

- Q: I recently moved into a 1975 house with aluminum wiring. I will be going through and checking/replacing all receptacles and switches with CO/ALR rated ones as I don't have a budget right now to rewire the house. I am wondering if I should be checking all of the ceiling lights as well as some of them would be very difficult to access. Are lights as big a concern with aluminum connections as receptacles? I am sure some of the lights are newer and would have copper wire connected to the aluminum. Should I be concerned about the type of wire nuts used here?Anything else that I should be checking?

- There's no problem with aluminum wiring that would require you to rewire your house as long as the proper wire gauge was used. You should replace all of the receptacles and switches with ones rated CO/AL. For lighting, replace the wirenuts with ones rated CO/AL and you'll be fine. From what I remember, Aluminum has a higher resistance than copper so it requires 1 size larger conductors. Aluminum also oxidizes faster than copper. If you have aluminum wires in your panel you should turn the main service disconnect off and put some de-oxidizer (you can find it at home improvement stores in the electrical section) where the wire lug is. This oxidation can make a bad connection causing you to lose voltage as the resistance goes up raising the amperage. This will generate more heat. Aluminum also... well its hard to explain... A/C current cycles its power in a sin wave, it causes the wire to vibrate. You will have to tighten all of the lugs on your electric panel periodically. The CO/AL wirenuts and receptacles/switches help prevent the vibration from loosening the connections causing a short and possibly a shock hazard or even a fire.

- Q: I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- aluminium wiring was very common in the '70's. there is nothing wrong with this wiring. it would be a lot better to have copper, but in your situation it is ok. to replace the wiring would be very labour intensive, and expensive. they likely wouldn't remove the whole wall and would do most of thee work in the basement and attic, if u have one. rewiring a house is like doing brain surgery in the dark. it is very important, though that u remember if u have any repairs, (ie: changing a recepticle, a switch, or breaker) you use aluminum compatible parts.

- Q: Heating aluminum plate, heating scheme, urgent ~!

- For aluminum heating silicon heating plate is a good choice. The four corners can be fixed by screws, Beijiao can. Installation is very convenient. I was in the goodway procurement. They are guaranteed for one year.

- Q: What specific tools or equipment are necessary for working with aluminum sheets?

- <p>Working with aluminum sheets typically requires a few specialized tools and equipment. These include a metal cutting saw for precise cuts, a metal file or sandpaper for smoothing edges, a metal shear for cutting, and a drill with metal bits for making holes. A roller or bending brake is useful for shaping the sheets, and a T-square or straight edge is important for marking straight lines. Safety equipment such as gloves, goggles, and a dust mask are also essential to protect against sharp edges and metal dust.</p>

Send your message to us

Aluminum Sheets for Siding - Aluminum Sheet and Cold Rolled Plate with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords