Extrusion Aluminum Profiles for Aluminium T-Profile Windows and Doors Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium T-profile for Windows and Doors Instalation Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium T-profile for Windows and Doors Instalation:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

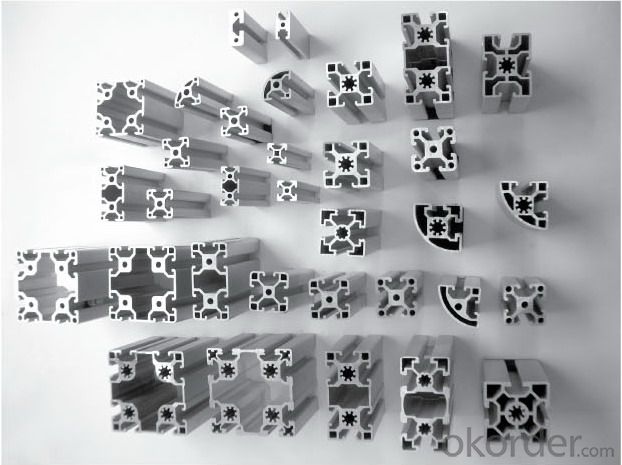

Images of the Aluminium T-profile for Windows and Doors Instalation:

Aluminium T-profile for Windows and Doors Instalation Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: T6 should be 140MPa, while the aluminum profile specification should be 150MPa. Should that be the standard?Code for design of glass curtain wall... And the calculation formula of bolt connection, what is the compressive strength value of aluminum profile?Prawns help you, 3Q~

- When the contact area of the fixture and the clamp decrease, the tension in the tensile process increases, and the change in the force area and bending moment, shear force, etc. will cause the increase of the local stress and the increase of bending moment.

- Q: This question asks if aluminum profiles can be recycled through existing recycling programs or facilities in the user's local area.

- <p>Yes, aluminum profiles can typically be recycled using existing recycling programs or facilities. Most recycling centers accept aluminum, and aluminum profiles are no exception. However, it's always a good idea to check with your local recycling program to confirm their specific guidelines and requirements. Some facilities may require aluminum profiles to be clean and free of any non-aluminum parts before recycling. You can also look for local scrapyards or metal recycling businesses that specialize in aluminum and may offer better rates for your aluminum profiles.</p>

- Q: What is the opening section of aluminum profile?

- Aluminum has an outer outline, an open outline, a closed outline, a plane to cut the opening, the plane is cut

- Q: What are the industries that require aluminum profiles in industry?

- 1, transportation (including automobile manufacturing, rail transportation).2 equipment and machinery manufacturing.3) durable consumer goods (including light industries).4, transportation, equipment and machinery and equipment manufacturing, durable consumer goods industry, respectively, in China's aluminum profile applications accounted for about 10%, 10% and 12%. While in Europe, North America and Japan aluminum consumption structure, industrial consumption ratio reached 60%, 55% and 40%, much higher than in China. It is expected in the next 5~10 years, China's consumption of aluminum industry will continue to grow in the aluminum products in the proportion of about 30% up to 2015 about 45~50%.5, aluminum plating process, which belongs to the coating technology it is pre plating and electroplating process steps to increase on the basis of conventional Ti process, aluminum is the process of the aqueous solution of salt and hydrochloric acid in the plating after activation of chemical treatment; electroplating bath composition including sulfur acid nickel, nickel chloride, boric acid twelve, sodium lauryl sulfate, saccharin, brightener, this process has the advantages of simple, practical and good effect, the titanium aluminum prepared by the hardness of the film is HV 1500, under the same conditions than the 22 carat gold plating wear 150 times, can be processed into various forms, golden color, black and bright various series of aluminum products.

- Q: Are aluminum profiles suitable for use in automotive body structures?

- Automotive body structures can indeed utilize aluminum profiles effectively. Aluminum, being a lightweight and durable material, offers numerous advantages in the automotive industry. Its high strength-to-weight ratio makes it an ideal option for constructing body frames, panels, and other structural components. The utilization of aluminum profiles in automotive body structures brings several benefits. Firstly, it enhances fuel efficiency by reducing the overall weight of the vehicle. This, in turn, leads to improved acceleration and handling. Moreover, aluminum exhibits exceptional corrosion resistance, allowing it to withstand harsh environmental conditions and increase the lifespan of the vehicle. Additionally, aluminum profiles can be easily shaped and molded into intricate designs, providing greater flexibility in automotive body structures. This versatility enables manufacturers to create more visually appealing and aerodynamic vehicles. While aluminum profiles offer a multitude of advantages, there are also some considerations to bear in mind. Aluminum can be more costly than traditional steel, potentially impacting the overall cost of the vehicle. Furthermore, the repair and maintenance of aluminum structures may require specialized equipment and expertise. Nevertheless, these factors are outweighed by the benefits aluminum profiles bring to the automotive industry. In conclusion, aluminum profiles are indeed suitable for use in automotive body structures due to their lightweight, durable, corrosion-resistant properties, and design flexibility. These characteristics make them an excellent choice for constructing modern vehicles.

- Q: Are there various ways to install aluminum profiles?

- <p>Yes, aluminum profiles can be installed using different methods. Common installation techniques include direct fastening with screws or bolts, using adhesives or sealants, and employing clip or channel systems. The choice of method depends on the specific application, load-bearing requirements, and aesthetic considerations. Some methods may provide quicker installation, while others might offer better structural integrity or visual appeal. It's important to consult with a professional or follow manufacturer guidelines to ensure the proper installation method is used for the intended application.</p>

- Q: Are aluminum profiles resistant to chemicals or solvents?

- Aluminum profiles, in general, exhibit resistance to chemicals and solvents. Aluminum is renowned for its exceptional ability to resist corrosion, which also translates to its resistance against the majority of chemicals and solvents. Nonetheless, it is crucial to acknowledge that the degree of resistance can fluctuate based on the particular chemical or solvent in question. Certain extremely corrosive chemicals or solvents might gradually impact aluminum profiles. Hence, seeking guidance from the manufacturer or performing precise tests is advisable to guarantee compatibility with a specific chemical or solvent.

- Q: What is the limitation of aluminum bending

- Stretch before aging. After aging, the hardness of the material is higher, and then the tension bend is cracked.

- Q: Are aluminum profiles capable of being tailored to fulfill unique design needs or standards?

- <p>Yes, aluminum profiles can be customized to meet specific design requirements or specifications. This customization can include varying the dimensions, finishes, and shapes to fit the intended application. Manufacturers can modify the extrusion process to create profiles with specific tolerances, surface treatments, and mechanical properties. This flexibility makes aluminum profiles suitable for a wide range of industries, including construction, automotive, and aerospace.</p>

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Extrusion Aluminum Profiles for Aluminium T-Profile Windows and Doors Installation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords