Aluminum Trim Profiles - Aluminium Sheet, Plate, and Slab Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled /cold drawn/hot rolled/hot drawn,aluminum sheet is widely usede field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 8000 series, 7000 sereis,

3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, F,H22, H24,O, H44,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

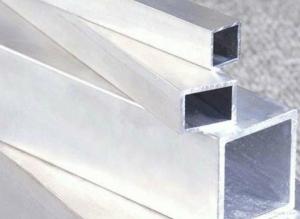

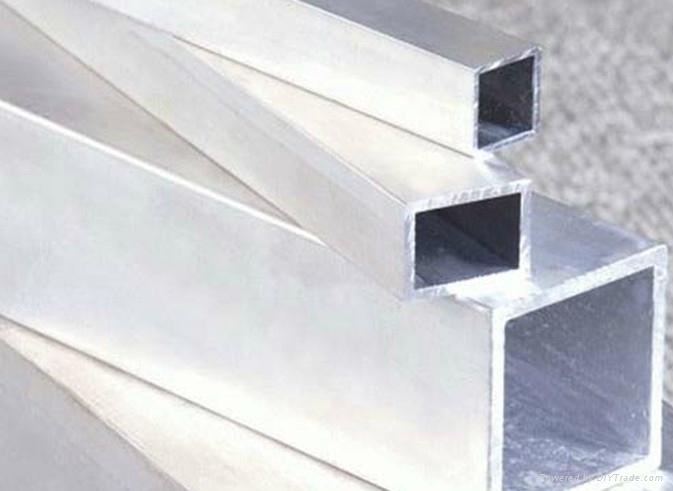

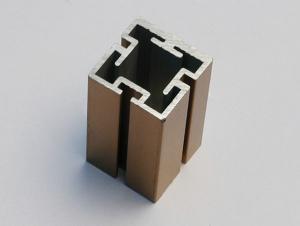

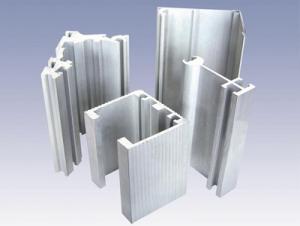

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the different surface protection options available for aluminum profiles?

- There are several surface protection options available for aluminum profiles, depending on the specific requirements and applications. 1. Anodizing: Anodizing is a commonly used surface treatment for aluminum profiles. It involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides excellent corrosion resistance, durability, and can also enhance the aesthetic appearance of the profiles by offering a range of colors. 2. Powder Coating: Powder coating is another popular surface protection option for aluminum profiles. In this process, a dry powder is electrostatically applied to the surface of the profiles, and then cured under heat to form a protective coating. Powder coating offers excellent durability, resistance to scratches, and comes in a variety of colors and finishes. 3. Painting: Painting is a traditional surface protection method for aluminum profiles. It involves applying a liquid paint coating to the surface, which provides protection against corrosion, UV radiation, and enhances the appearance. Painting allows for a wide range of colors and finishes, making it suitable for various aesthetic requirements. 4. Clear Coating: Clear coating is often used when the natural appearance of the aluminum profiles needs to be preserved while providing protection. This coating forms a transparent film on the surface, protecting it from oxidation, scratches, and other environmental factors, while still showcasing the metallic look of the aluminum. 5. Film Coating: Film coating, also known as protective film or peelable coating, is a temporary surface protection option. It involves applying a thin layer of film onto the aluminum profiles to protect them during transportation, handling, or installation. This film can be easily peeled off after the profiles are installed, leaving a clean and unharmed surface. 6. Mechanical Finishing: Mechanical finishing techniques like brushing, polishing, or sandblasting can be used to improve the surface appearance of aluminum profiles. These methods can help achieve a desired texture, gloss level, or remove any imperfections on the surface. While these techniques do not provide long-term protection, they can be combined with other surface protection options for enhanced aesthetics. Overall, the choice of surface protection option for aluminum profiles depends on factors such as the intended application, desired aesthetics, durability requirements, and cost considerations. It is important to select the most suitable option based on these factors to ensure the longevity and performance of the profiles.

- Q: Are aluminum profiles suitable for use as exterior wall materials?

- <p>Yes, aluminum profiles can be used for exterior walls. They are known for their durability, resistance to weathering, and low maintenance requirements. Aluminum is lightweight, strong, and can be easily shaped into various designs. It also has excellent resistance to corrosion, making it ideal for outdoor applications. Additionally, aluminum profiles can be powder coated or anodized for enhanced protection and aesthetic appeal, allowing them to blend well with different architectural styles.</p>

- Q: Is it possible to utilize recycled aluminum products as an alternative to new ones to decrease environmental impact and save costs?

- <p>Yes, using recycled aluminum products is an effective way to reduce environmental impact and cost. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials, which reduces greenhouse gas emissions. Additionally, recycled aluminum retains the same properties as new aluminum, making it a viable alternative for many applications. This practice not only conserves resources but also lowers production costs, making it a sustainable choice for both the environment and your budget.</p>

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- Is it ready to estimate?. Custom mold. If the simple section of the mold is about two thousand yuan (our company has many of these profiles on the outside to buy), the mold fee is in a certain amount can be returned.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: What are the different bending radii available for aluminum profiles?

- The different bending radii available for aluminum profiles can vary depending on the specific profile and its dimensions. However, common bending radii for aluminum profiles typically range from 1.5 to 3 times the profile's wall thickness.

- Q: Can aluminum profiles be subjected to painting or coating processes to improve their aesthetic appeal and resistance to wear?

- <p>Yes, aluminum profiles can be painted or coated. This process not only enhances their appearance but also significantly improves their durability and resistance to corrosion. Aluminum has a natural oxide layer that provides some protection, but painting or coating can offer additional layers of defense against environmental factors. These coatings can be applied through various methods such as powder coating, anodizing, or electrophoretic deposition, each providing a different finish and level of protection. The choice of coating depends on the specific requirements for appearance, performance, and the environment in which the aluminum profile will be used.</p>

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Warehouse and storage systems can utilize aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, which make them suitable for a variety of applications in warehouses and storage systems. They can be utilized for the construction of shelving units, racks, and partitions in order to optimize storage space and arrange inventory. Aluminum profiles are also highly versatile, allowing for easy customization and assembly to fulfill specific storage requirements. Furthermore, these profiles offer an exceptional strength-to-weight ratio, enabling them to support heavy loads without compromising the structural integrity. Overall, due to their durability, flexibility, and cost-effectiveness, aluminum profiles are widely preferred in warehouse and storage systems.

- Q: How is the thickness of the base plate of the aluminum profile radiator calculated? Are there formulas for calculation?

- There should be empirical formula, the heat of the surface heat dissipation is related to thermal conductivity, thickness, temperature change, surface area. Then the best thickness is calculated by linear programming.

- Q: Where is the exact location? TwentyBecause I was doing aluminum sales, want to go to the market!Where is the specific market aluminum sales, as long as there is, I have to go around! Say where it is! For example, what area, what road, how many?! Since I went to Chengdu for the first time, please tell me more about it. Thank you!

- 512 building materials market 'The two ring road north station over there direction

Send your message to us

Aluminum Trim Profiles - Aluminium Sheet, Plate, and Slab Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords