Standard Aluminum Profiles - Aluminum Sheet Plate Stocks Warehouse Cold Rolled Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

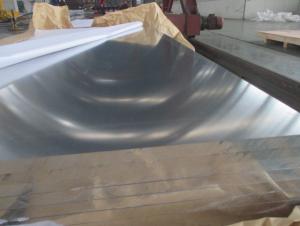

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Request recommended professional aluminum manufacturer?

- Jing Long aluminum, aluminum strip and aluminum wafer production capacity of 60000 tons, this piece in Shangqiu, still have the strength, is a professional production and processing, wholesale distribution of aluminum, hot-rolled plate, hot rolled plate, aluminum plate, aluminum plate, roll spindle is the main.

- Q: How to prevent the aging of aluminum profile hardness is not enough?

- Raw materials, alloy, cast bar qualityDuring extrusion, the outlet temperature is guaranteed to be above the solid solution temperature,Cooling, quenching speed guaranteed as fast as possible

- Q: What are the differences between horizontal and vertical aluminum profiles?

- Horizontal vertical hanger in the middle on the head,Therefore, the horizontal number will affect the surface a little, and when you have to find non decorative surface hangingThe vertical head is better, a hanging point, just cut off

- Q: What is the difference between 6063-T5 and 6061-T6 aluminum profiles?

- At present, microstructure and mechanical properties of joint changes have some preliminary research on the welding of 6000 Aluminum Alloy, Department of the welding joint part of the alloy softening phenomenon is more serious, the main reason is the influence of softening joint welding thermal cycle of reinforcement particles occurred in aging and coarsening. The above research mainly concentrated in the softening behavior of welding, microstructure and heat affected zone of alloy, but on the 6063 Aluminum Alloy changes the mechanical properties of welding joints and welding thermal cycle and the relationship between the effect of artificial aging is also a lack of detailed research. The T5 condition is aging and natural cooling! The coefficient of deformation is small and easy to control! General hardness! T6 status is water cooled! Large coefficient of deformation! Not easy to control! High hardness!

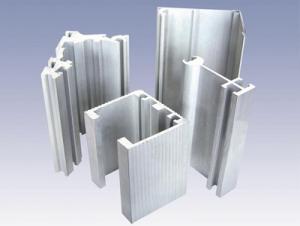

- Q: Can aluminum profiles be used in the construction of modular buildings?

- Modular buildings can benefit from the utilization of aluminum profiles. These profiles possess a combination of lightweight properties and strength, ensuring durability and making them a perfect material for modular construction. Their fabrication and joining processes are straightforward, enabling flexibility in both design and construction. Furthermore, aluminum profiles showcase exceptional resistance to corrosion, a vital characteristic for modular buildings that might face diverse weather conditions. Moreover, the employment of aluminum profiles in modular construction can contribute significantly to sustainability since aluminum is highly recyclable. Due to these advantages, aluminum profiles have become a favored choice in the industry for constructing modular buildings.

- Q: Are aluminum profiles suitable for solar panel frames?

- Yes, aluminum profiles are highly suitable for solar panel frames. Aluminum is a lightweight yet strong material, making it an ideal choice for constructing solar panel frames. It offers excellent corrosion resistance, which is crucial for outdoor applications, ensuring the longevity and durability of the frames. Additionally, aluminum profiles can be easily shaped and formed, allowing for flexible and customizable designs to accommodate different solar panel sizes and configurations. Furthermore, aluminum is a highly sustainable material as it is 100% recyclable, aligning with the environmentally-friendly nature of solar energy. Overall, the use of aluminum profiles for solar panel frames provides numerous advantages such as strength, durability, corrosion resistance, flexibility, and sustainability, making it a highly suitable choice.

- Q: What are the potential effects on the environment when aluminum profiles are used in the construction of buildings?

- <p>The use of aluminum profiles in building construction has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, which reduces the energy required for transportation and can contribute to a building's energy efficiency. It is also recyclable, with a high recycling rate, which helps to conserve resources and reduce waste. However, the production of aluminum is energy-intensive and generates greenhouse gas emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The environmental impact of using aluminum profiles in construction must therefore be balanced against these factors.</p>

- Q: Many aluminum extrusions are edge banding materials. What special advantages do they have for opening materials?.

- Sealing material does not open well. Most of the sealing material is old style, new openings are more, with the sealing material to the landlord to see, it will feel that the amount of material enough, you can raise the landlord's price.

- Q: Are aluminum profiles suitable for outdoor sign applications?

- <p>Yes, aluminum profiles are commonly used for outdoor signage due to their durability, resistance to corrosion, and lightweight properties. They can withstand various weather conditions without rusting or fading, making them an ideal material for long-lasting outdoor signs. Aluminum profiles can be easily cut, shaped, and assembled, offering flexibility in design and functionality.</p>

- Q: Do aluminum profiles require any special tools or equipment for installation?

- Yes, aluminum profiles typically require specific tools and equipment for installation. These may include a miter saw or aluminum cutting saw, drill press or power drill, measuring tools, screwdrivers, clamps, and fasteners specific to aluminum profiles. Additionally, certain installations may require specialized equipment such as a router or end milling machine for precision cuts and shaping.

Send your message to us

Standard Aluminum Profiles - Aluminum Sheet Plate Stocks Warehouse Cold Rolled Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords