Aluminum Extrusion Profiles from Japan - Aluminium Sheet Best Better Price with Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

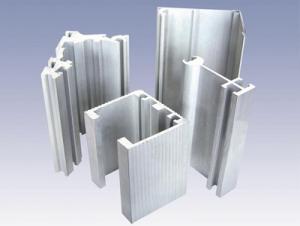

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it6s around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, cold rolled ss sheet, hot rolled ss sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the different cutting options available for aluminum profiles?

- Some of the different cutting options available for aluminum profiles include sawing, shearing, laser cutting, and waterjet cutting. Each method has its advantages and is chosen based on factors such as precision requirements, budget, material thickness, and production volume.

- Q: What are the reasons for the slow down of aluminum extrusion press?

- Try to adjust it properlyCheck for premature transferCheck whether the reaction speed of the filling valve is fast enoughThink of the above five points temporarily. Hope to be of some help to you.

- Q: What are the bending radii for different aluminum profiles?

- The bending radii for different aluminum profiles can vary depending on the specific shape and thickness of the profile. However, in general, aluminum profiles can be bent to a minimum radius that is typically around 1.5 to 2 times the thickness of the material. For example, if you have an aluminum profile with a thickness of 1mm, the minimum bending radius would be around 1.5 to 2mm. Similarly, if the profile has a thickness of 3mm, the minimum bending radius would be around 4.5 to 6mm. It is important to note that these are approximate values and may vary depending on the specific alloy and temper of the aluminum. Additionally, the bending process itself, including the method and equipment used, can also impact the achievable bending radii. To ensure accurate bending, it is recommended to consult the manufacturer or a professional fabricator who can provide specific guidelines and recommendations for bending radii based on the particular aluminum profile you are working with.

- Q: Are aluminum profiles suitable for material handling equipment?

- Yes, aluminum profiles are suitable for material handling equipment. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it ideal for applications that require easy maneuverability and lifting capacities. Additionally, aluminum profiles can be easily customized and assembled, allowing for versatile designs that can meet various material handling needs.

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum extrusions, which are shaped profiles made from aluminum.

- <p>Aluminum extrusions can be finished in several ways to enhance their appearance, durability, or functionality. Common finishes include anodizing, which provides a protective oxide layer; powder coating, offering a wide range of colors and textures; painting, which can be done electrostatically or by hand; polishing, resulting in a shiny, smooth surface; brushing, which creates a satin-like finish; and chromate conversion coating, which is a pretreatment for further painting or coating. Other finishes include wood grain transfer, which gives an aluminum surface a wood-like appearance, and various types of protective films or laminates. Each finish serves different purposes, from improving aesthetics to increasing corrosion resistance.</p>

- Q: How are aluminum profiles insulated?

- Aluminum profiles are typically insulated using a thermal break system. This involves placing a non-conductive material, such as polyamide or polyurethane, between the inner and outer sections of the aluminum frame. This insulation helps to reduce heat transfer and improve energy efficiency in buildings.

- Q: Can aluminum profiles be used in the construction industry?

- The construction industry can utilize aluminum profiles, which possess qualities such as being lightweight, durable, and resistant to corrosion. These attributes make them suitable for a wide range of construction applications. Aluminum profiles are commonly employed in the production of windows, doors, curtain walls, and structural framing systems. They offer an excellent strength-to-weight ratio, enabling the creation of large and intricate structures without excessive weight. Furthermore, they are easily molded into various shapes and sizes, providing flexibility in design and construction. The thermal conductivity of aluminum profiles is also advantageous, as it allows for efficient insulation and energy conservation. All in all, due to their versatility, durability, and aesthetic appeal, aluminum profiles are a favored choice in the construction industry.

- Q: This question asks about the impact of aluminum profiles on the sound insulation properties of a building.

- <p>Aluminum profiles can significantly affect the sound insulation of a building. They are often used in construction for their strength and lightweight properties. However, aluminum is a good conductor of sound, which can lead to sound transmission through the building structure. To enhance sound insulation, aluminum profiles are often combined with soundproofing materials such as acoustic foam or rubber seals. These materials help to absorb or block sound waves, reducing noise transmission. Additionally, the design and installation of aluminum profiles can also impact sound insulation; proper sealing and insulation techniques are crucial to minimize sound leakage.</p>

- Q: 30*40 how much aluminum meter?

- 30*40 aluminum tube color of grain price is generally about 13.6-19.8.

- Q: Measuring 3 meters long aluminum profiles of the straightness, you have what good method? What is the maximum deviation value allowed by our industry? In addition to the platform measurement, and what are the economic and practical methods, our factory stalls are small. Consider input costs.

- The friend the profiles of the straightness, don't know you mean curvature profile, or twist, there are clear provisions in the building material standard GB5237-2008 and GB/T6892-2006 standard in all industrial sections, such as building materials in the standard GB5237-2008, the bending degree is divided into ordinary grade, high grade, high precision class.

Send your message to us

Aluminum Extrusion Profiles from Japan - Aluminium Sheet Best Better Price with Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords